Positive and Negative Pressure Rooms 101: All You Need to Know

How Air Pressure Impacts Healthcare Safety and Compliance

Effective climate control systems are essential in many different settings, including medical and research facilities.

One major application of these systems is the use of positive and negative pressure rooms.

These specialized environments help prevent the spread of infectious contaminants, maintain the integrity of sterile or restricted spaces, and protect both patients and healthcare professionals.

Monitoring and measuring these spaces can be a critical piece of information related to compliance with federal agencies that enforce strict guidelines around air pressure aimed at safety.

There are significant and diverse consequences for failing to maintain appropriate air pressure conditions in a host of environments, from healthcare and life science settings to advanced manufacturing and food preparation, including:

- Damage to equipment: Air pressure that is too high or too low can damage sensitive equipment, such as computers, medical devices, and scientific instruments.

- Health risks: Air pressure that is too low can cause headaches, dizziness, and nausea. Air pressure that is too high can cause ear pain, sinus pain, and difficulty breathing.

- Infection control: Air pressure that is too low can make it easier for bacteria and viruses to spread. This is a particular concern in healthcare settings, where patients are already at risk of infection.

- Product spoilage: Air pressure that is too low can cause food and other products to spoil. This is a particular concern in food processing and storage facilities.

- Fire risk: Air pressure that is too low can make it more difficult to extinguish fires. This is a particular concern in industrial settings, where fires can be large and dangerous.

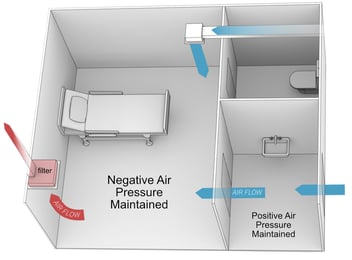

Positive pressure rooms: Where the air streams out

Otherwise known as protective environments, positive pressure rooms are designed to maintain a higher pressure within the treated space than that of the surrounding spaces.

In other words, in such a room, air may leave without circulating back in. So any airborne particles that originate from within the positive pressure room will be efficiently filtered out.

While germs and potential contaminants in the surrounding spaces will not gain entry into the room.

Positive pressure rooms are particularly indispensable in medical settings since they allow healthcare professionals to keep vulnerable patients safe from infections and disease.

These rooms require specialized construction and climate control equipment to remain effective, including:

- No less than twelve airflow changes per hour must be maintained to sustain the desired pressurized environment. Depending on the size and purpose of the room, more airflow changes may be necessary.

- Recirculation of air through HEPA filters helps control the movement of airborne contaminants.

- A self-closing entryway with adequate sealing prevents air from escaping. Thoroughly sealed floors, ceilings, walls, and windows also play a role in helping maintain a positive pressure environment.

- Fans and ductwork move air in the desired direction.

- A monitoring system enables users to adjust pressure levels whenever necessary.

- An intermediate environment between the positive pressure room and the outside environment is often reserved for deliveries, observations, and storing protective gear.

- Some healthcare facilities integrate UV radiation into the system to help maintain a sterile environment.

Positive pressure rooms have different applications in different medical and research settings.

They are especially useful when treating patients with compromised immune systems because any harmful element that’s introduced into the room will be efficiently filtered out.

Positive pressure rooms are also useful in situations where a specific type of atmosphere must be consistently maintained in the room like in human and animal nurseries.

Other uses of these systems include in vitro fertilization labs and operating theaters.

Sonicu provides a comprehensive suite of monitoring applications designed to help professionals focused on capturing compliance data around air pressure differentials in hospitals and laboratory settings.

Designed to be easy to install and simple to use, the Sonicu environmental monitoring systems can be deployed by a non-technical healthcare employee while the reporting in the SoniCloud system is pre-configured to meet the strict requirements of healthcare and life science regulatory agencies.

This case study, from a California-based manufacturing company, demonstrates how easy it is to deploy Sonicu’s air pressure differential monitoring system and how it can be transported between different locations.

Exide Technologies: Mobile Air Pressure Monitoring

Negative pressure rooms

Unlike positive pressure rooms, these rooms leverage lower air pressure to permit outside air into the segregated environment.

This traps and keeps potentially harmful particles within a negative pressure room by preventing internal air from leaving the space.

These rooms are indispensable to healthcare facilities where patients with infectious diseases are isolated to protect people in the surrounding spaces from exposure.

Negative pressure rooms are also referred to as airborne infection isolation rooms (AIIRs).

Like the positive variety, AIIRs require specialized construction and climate control equipment to work as desired.

- They require at least twelve airflow changes per hour to sustain the desired environment.

- Recirculation of air through HEPA filters helps regulate the movement of airborne contaminants.

- A self-closing entryway with adequate seals prevents air from escaping. Thoroughly sealed floors, ceilings, walls, and windows help maintain a negative-pressure environment.

- Fans and ductwork relay air in the desired direction.

- A monitoring system allows users to adjust pressure levels whenever necessary.

Negative pressure rooms play a critical role in helping control the spread of infectious diseases within large healthcare facilities like hospitals.

Hospitals use them in in-patient rooms to ensure infectious germs cannot spread throughout the facility via the HVAC system.

They are also used in other areas of the hospital, including:

- emergency rooms

- triage areas

- bathrooms

- autopsy and dark rooms

- soiled laundry rooms

- and decontamination spaces

The Sonicu air pressure monitoring system can capture the data to ensure your negative pressure environment is performing as required and that you’re ready to validate compliance with a regulatory agency.

Hospitals, clinics, laboratories and manufacturing facilities across the country rely on Sonicu for affordable and simple air pressure differential monitoring

Installing positive and negative pressure rooms

Installing a pressurized room is a complex task that demands careful planning to make sure the room seamlessly suits the facility’s needs and space, conforms to applicable regulations, and protects patients and the general public from the spread of infectious diseases.

Properly installed positive and negative pressure rooms can be instrumental in preserving a healthy environment for hospital patients or one compromised by dangerous pathogens.

Proper installation of a pressurized room is essential to its effectiveness in controlling airborne contaminants.

Hospital managers should enlist the services of experienced and skilled contractors with the necessary expertise in designing and constructing these sorts of rooms to guarantee all requirements are met.

Below are the steps commonly involved in the installation of a positive or negative pressure room.

- Assess the needs of the space: before installing a pressurized room, it is crucial to first figure out the specific requirements of the space. This may include the intended use of the room, the variety of contaminants it has to filter, and its ideal size and layout.

- Design the room: based on the requirements of the space, you can develop a design plan for the pressurized room. Some of the tasks involved are figuring out the room’s placement within the building, the space’s layout, and the equipment needed.

- Select the right materials: positive and negative pressure rooms require specific materials to be able to maintain the desired air pressure and prevent contamination. Such materials may include specialized doors, windows, flooring, and wall panels.

- Install an airflow system: the airflow system is an indispensable component of a pressurized room. It comprises HVAC equipment, ductwork, and filters which ensure the air within the space is consistently filtered and circulated to maintain the desired pressure and avert contamination.

- Install a monitoring system: monitoring systems are needed to guarantee that the pressurized room maintains acceptable air pressure and quality. Such a system consists of sensors that continuously take readings of air pressure, temperature, and humidity in the room and can then alert hospital staff if the levels fall or rise beyond the acceptable range.

In conclusion, positive and negative pressure rooms are indispensable components of modern healthcare facilities and research centers.

By helping prevent the spread of infectious diseases, they play a key role in keeping people safe and healthy.