Understanding Heat Stress and OSHA Regulations: How to Protect Your Employees and Ensure Compliance

How remote temperature monitoring can support your Heat Stress Readiness Plan

Healthcare workers in the United States are all too familiar with the increasing dangers of heat-related illnesses.

“Nearly 120,000 heat-related emergency room visits were recorded across the United States (in 2023), according to the Centers for Disease Control and Prevention,” The New York Times reported recently in a story about the issue of the rise of heat-related emergencies.

While the nation’s healthcare workers have been busy tending to those who have fallen ill due to heat-related issues, the nation’s policymakers are focused on crafting regulations to protect workers from the increasingly serious threat of indoor heat at work.

Healthcare workers themselves are among those that the regulators seek to protect with these new regulations.

In a news release issued in July 2024, OSHA said that “the U.S. Department of Labor has released a proposed rule with the goal of protecting millions of workers from the significant health risks of extreme heat.

If finalized, the proposed rule would help protect approximately 36 million workers in indoor and outdoor work settings and substantially reduce heat injuries, illnesses, and deaths in the workplace.”

Similarly, in California, under increasing pressure from workers, Cal/OSHA issued a Heat Illness Prevention in Indoor Places of Employment regulation that applies to most indoor workplaces, such as restaurants, warehouses, and manufacturing facilities where temperatures can get high.

Sonicu is working with some of the largest and most respected organizations across California today to deploy simple and affordable temperature monitoring solutions that can play a crucial role in providing reliable, actionable data for health and safety professionals as well as front-line managers in their work to adhere to these strict new California policies.

“For indoor workplaces where the temperature reaches 82 degrees Fahrenheit, employers must take steps to protect workers from heat illness,” the State of California’s Department of Industrial Relations said. Some requirements include providing water, rest, cool-down areas, methods for cooling down the work areas under certain conditions, and training.

Keeping reliable and searchable heat index logs is also part of the regulatory policy.

Healthcare workers don’t just tend to those suffering from heat stress; they are also among the most vulnerable workers to suffer from such illnesses themselves.

“Healthcare professionals are often at risk of experiencing heat exhaustion and related illnesses during the hotter months or in environments with high temperatures,” according to Supplemental Health Care, a staffing firm for healthcare employers.

“The combination of working long hours in physically demanding settings and wearing personal protective equipment (PPE) can increase opportunities for heat exhaustion or illness to develop.”

Heat stress is an increasingly important issue across various industries, especially in the wake of rising global temperatures.

While manufacturers, warehouses, agriculture, and logistics organizations are some of the most obvious industries regulators are focused on protecting, employers in the life sciences, pharmacies, healthcare, and food service industries must take proactive steps to mitigate the risks associated with heat exposure to their employees, ensuring compliance with OSHA regulations.

As OSHA continues to refine its guidelines and introduce new rules, companies must stay informed and implement strategies to safeguard worker health and ensure compliance.

This article will look at what companies in these sectors need to know about heat stress, explore the new OSHA rules, and highlight the importance of environmental and temperature monitoring systems to protect employees and prevent potential liabilities.

This video shows how employers leverage Sonicu’s monitoring system to track key conditions.

What Is Heat Stress?

Heat stress refers to a situation where the body cannot cool itself effectively, leading to heat-related illnesses such as heat stroke, heat exhaustion, heat cramps, and heat rashes.

The body maintains a stable temperature through a delicate balance of heat production and heat loss.

In hot environments or during physical exertion, the body dissipates heat mainly through sweat evaporation and increased blood flow to the skin.

When external conditions prevent the body from shedding excess heat, workers become susceptible to heat stress. The rising temperatures in nearly all parts of the country are prompting regulatory agencies to focus on heat stress as a new threat to employees that requires oversight.

Key Heat Stress Symptoms Include:

- Heat stroke: This is the most severe form of heat illness, characterized by confusion, loss of consciousness, and potentially fatal complications if untreated. It occurs when the body's temperature regulation fails, causing the core temperature to rise above 104°F (40°C).

- Heat exhaustion: Symptoms include heavy sweating, weakness, dizziness, headache, nausea, and fainting. Workers with heat exhaustion must be treated promptly to avoid escalation to heat stroke.

- Heat cramps: Painful muscle cramps or spasms are usually caused by heavy sweating during intense physical labor. Rest and electrolyte replenishment can help prevent heat cramps.

- Heat rash: This occurs when sweat is trapped under the skin, causing irritation and discomfort. Workers in hot, humid environments are particularly prone to heat rash.

Heat Stress Risks in Different Sectors

The risks of heat stress vary depending on the industry:

- Life Sciences and Pharmacies: Laboratory environments with high heat-generating equipment, such as autoclaves, centrifuges, and large freezers, can create localized hot spots. Additionally, employees working with PPE may face reduced heat dissipation, increasing the risk of heat-related illnesses.

- Healthcare: Healthcare workers, especially those in kitchens or laundry rooms, can be exposed to high heat levels. Emergency response personnel may also be exposed to extreme heat when responding to outdoor emergencies during heat waves.

- Food Service: Kitchen staff work in environments with high ambient temperatures due to stoves, ovens, and grills. Food delivery personnel, particularly those working outdoors during heatwaves, are also at risk.

OSHA Heat Stress Guidelines

OSHA provides comprehensive guidelines on heat stress, urging employers to take preventive measures to protect workers. These guidelines focus on identifying risk factors, monitoring worker health, and implementing control strategies to prevent heat-related illnesses.

Key Components of OSHA's Heat Stress Guidelines:

- Training and Awareness: Employers must train workers to recognize the signs of heat stress and provide them with guidance on how to respond in case of symptoms.

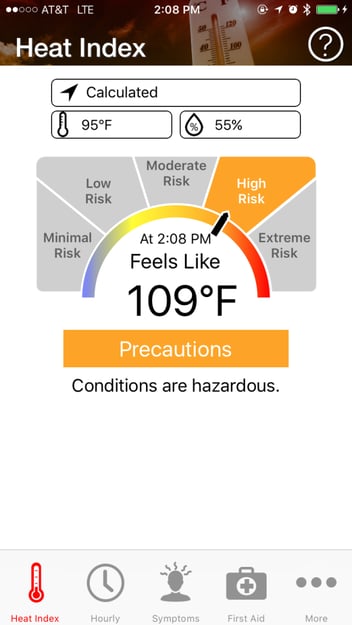

- Monitoring Environmental Conditions: Employers should regularly monitor temperature, humidity, and other environmental factors that influence heat stress, such as radiant heat from equipment or surfaces.

- Hydration and Rest Breaks: Workers should have access to cool water, and regular rest breaks should be implemented, especially during high heat conditions. OSHA recommends drinking water every 15-20 minutes when working in hot conditions.

- Acclimatization Programs: Employers should introduce workers gradually to hot environments, allowing them to acclimatize to higher temperatures. This is crucial for new employees or those returning after extended periods away from work.

- Engineering Controls: Employers should take steps to reduce heat exposure through engineering controls such as increasing ventilation, installing fans, using heat shields, and improving air conditioning systems.

- PPE Considerations: Special attention should be paid to workers required to wear PPE, as these can limit the body’s ability to dissipate heat. Proper PPE selection is crucial to minimizing heat-related risks.

New OSHA Rules for Employers on Heat Stress

In response to rising temperatures and the increasing frequency of heatwaves, OSHA has implemented new rules that hold employers more accountable for protecting workers from heat stress.

These rules are particularly relevant for industries with high-risk exposure, including life sciences, pharmacies, hospitals, and food service.

1. The National Emphasis Program (NEP) on Heat Illness Prevention:

In 2022, OSHA launched its National Emphasis Program (NEP) focusing on heat-related hazards. This program aims to:

- Target industries and worksites where workers are most at risk of heat stress, including indoor and outdoor environments.

- Conduct proactive inspections and audits of workplaces with high heat exposure risks, such as those in healthcare, food service, and life sciences.

- Enforce heat-related safety measures by requiring employers to implement proper heat illness prevention protocols, conduct risk assessments, and ensure appropriate PPE usage.

2. Mandatory Heat Illness Prevention Plans:

Under the new OSHA rules, employers must now develop formalized Heat Illness Prevention Plans (HIPP) for workplaces where heat hazards are prevalent.

A comprehensive HIPP should include:

- Hazard assessments to identify heat-related risks in various areas of the workplace.

- Protocols for providing cooling solutions like air conditioning or fans in work areas, shaded rest zones, and easily accessible hydration stations.

- Emergency response procedures in the event of a heat-related illness, including first-aid measures and immediate access to medical care.

- Worker training programs that emphasize the importance of recognizing early symptoms of heat stress and reporting them.

Employers must review these plans periodically and update them in response to changing environmental conditions or workplace practices.

3. Heat Stress Monitoring and Record-Keeping:

New OSHA guidelines emphasize the importance of heat stress monitoring. Companies must now monitor workplace temperatures and humidity levels, particularly during heatwaves or high-risk conditions. Furthermore, employers are required to maintain records of any heat-related incidents and corrective actions taken.

Heat-related illnesses are now part of OSHA’s injury and illness record-keeping requirements. This means that employers must report heat-related incidents that result in hospitalization or lost workdays.

4. Acclimatization Requirements:

The new OSHA rules require employers to implement acclimatization protocols, especially for new workers or those returning after an extended absence. Acclimatization allows workers to gradually adjust to working in hot environments, reducing the likelihood of heat-related illnesses.

Key aspects of acclimatization include:

- Gradual exposure to increasing heat levels over a period of days or weeks.

- Adjusting workloads during the initial days of exposure to avoid overexertion.

- Continuous monitoring of acclimatized workers to ensure that they maintain their ability to tolerate heat over time.

Technological Solutions for Monitoring and Mitigating Heat Stress

Employers in life sciences, pharmacies, healthcare, and food service can leverage advanced technologies to comply with OSHA's heat stress regulations and enhance worker safety.

Wireless environmental monitoring systems, wearable devices, and remote wireless temperature monitoring systems sensors, like those from Sonicu, are key tools that help monitor temperature and humidity levels, track worker health, and send real-time alerts in case of dangerous conditions.

1. Wireless Environmental Monitoring Systems:

Wireless environmental monitoring systems can track temperature, humidity, and air quality across different areas of a workplace. These systems use sensors to provide real-time data on environmental conditions, allowing employers to identify heat hotspots and take corrective action.

In industries such as life sciences and pharmacies, where temperature-sensitive products are stored, these systems not only protect workers but also ensure product safety and compliance with regulatory requirements. For instance, monitoring the temperature in laboratories, freezers, and storage areas can prevent both heat-related worker illness and damage to temperature-sensitive products.

.png?width=600&height=300&name=Sonicu%20Devices%20(1).png)

2. Wearable Heat Monitoring Devices:

Wearable heat-monitoring devices, such as smart bands or body temperature sensors, help track workers’ physiological responses to heat. These devices can monitor core body temperature, heart rate, and sweat rate, alerting workers and supervisors when an individual is at risk of heat stress.

These wearables can be particularly useful for outdoor workers, delivery personnel, or employees working in confined spaces where temperatures may rise unexpectedly. Organizations looking to improve their data collection and preemptive monitoring to maximize employee protection may couple a wireless monitoring system like Sonicu with wearable sensors for employees in particularly risky environments.

By providing real-time alerts, these devices empower workers to take precautionary measures like hydrating or taking breaks before symptoms escalate. And all of these sensor options demonstrate to employees that organizations are taking the serious threat of heat stress.

3. Automated Heat Stress Alerts:

Employers can also integrate automated heat stress alerts into their safety systems. These alerts can notify workers via mobile apps or other communication devices when environmental conditions exceed safe limits.

For instance, if the temperature or humidity levels in a kitchen, laboratory, or hospital laundry room reach dangerous levels, an automated alert system can notify the relevant teams to take immediate action, such as increasing ventilation or taking rest breaks.

Sonicu helps companies manage the risk of heat stress by delivering affordable and simple heat stress monitoring technology that employers can deploy rapidly and keep track of their heat stress situation from virtually anywhere.

You can learn more about how our software helps compliance professionals in these case studies:

Hamilton County, Indiana Health Department: Vaccine Monitoring

Katherine Shaw Bethea Hospital: Pharmacy Monitoring for Remote Clinics

Nomi Health: Fast installation, simple deployment

Compliance and Best Practices

For companies in any industry, complying with OSHA’s heat stress rules is not just about meeting regulatory requirements. It is about creating a safer workplace, improving employee well-being, and minimizing the risk of heat-related incidents. Employers should:

- Conduct regular heat risk assessments to identify areas where workers are most vulnerable to heat stress.

- Implement a formal Heat Illness Prevention Plan (HIPP) that includes acclimatization protocols, emergency response measures, and strategies for minimizing heat exposure.

- Leverage technology like wireless environmental monitoring systems, wearable devices, and automated heat stress alerts to enhance heat monitoring and early intervention.

- Provide training that helps workers recognize the early signs of heat stress and take appropriate action.

- Maintain clear records of any heat-related incidents and the measures taken to prevent future occurrences.

- Ensure continuous communication between employees and supervisors regarding heat conditions and necessary precautions.

Heat stress is a serious concern for employers across the life sciences, pharmacies, healthcare, and food service sectors.

OSHA’s evolving regulations, including the NEP and mandatory HIPPs, require companies to take proactive measures to protect their workers.

By implementing proper training, monitoring environmental conditions, using technology to track worker health, and fostering a culture of safety, employers can prevent heat-related illnesses and ensure a compliant and safe work environment.

Adopting a comprehensive approach not only mitigates health risks but also improves employee productivity, morale, and overall workplace safety.

Sonicu can play an instrumental role in any heat-stress workplace program with our simple and affordable monitoring that is already trusted by scores of health and safety professionals working to protect employees from the dangers of heat-related workplace injuries.