Differential Air Pressure System

If you are looking for a differential air pressure system equipment that helps you and your team eliminate manual logging, improve compliance readiness, and protect all your temperature-sensitive assets, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts to protect assets

- Compliance: Automated reports

- Efficiency: Reduced Manual Logging

And what makes us different?

- Lifetime Warranty: Never buy hardware again!

- Unlimited Users: Scale across your entire org

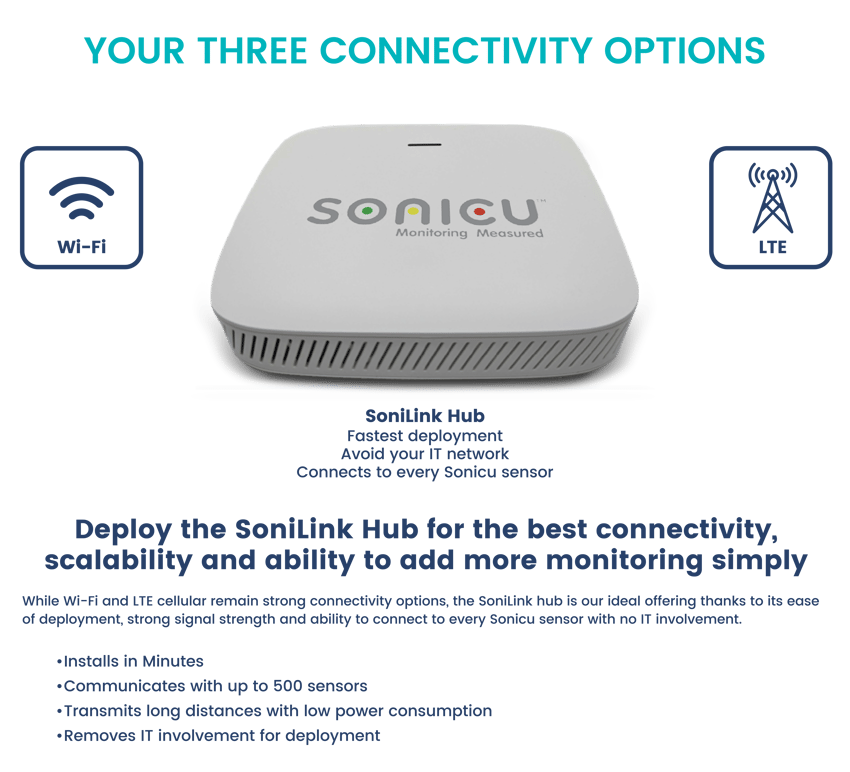

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

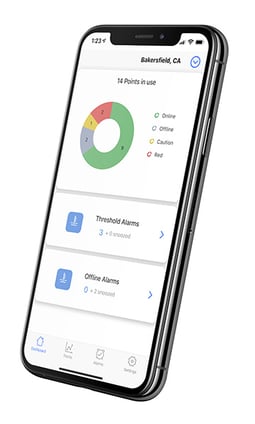

- Mobile App: 500 Freezers in your pocket

All American made and supported!

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

Differential Air Pressure System

Some of the finest names in healthcare, including Indiana University Health, University of Michigan Health System, and Stanford University rely on Sonicu to provide a robust and continuous environmental monitoring system, including temperature, humidity, air pressure, and more.

These respected healthcare and research brands turn to Sonicu for four primary reasons:

- Real-Time Monitoring: the sensors collect temperature, humidity, air pressure data, and more, and transmit it wirelessly to SoniCloud - our cloud-based platform.

- Operational Efficiency: Virtually eliminate the need for tedious and costly manual logging

- Compliance Automation: Respond to any regulatory audit or inspection in a few clicks with our reports section

- Asset Protection: Detect and respond to any threshold that can threaten anything perishable: food, drugs, vaccines, research, etc.

Our customers stay with us thanks to our American-based customer support, which is never more than a phone call away. While our technology is intuitive and powerful, we know it’s only as strong as the people who stand behind it.

Engaging with the vocabulary of science and technology, one might come across terms that seem like crosswords designed for scientific scholars.

Yet, when simplified, anyone can understand these terms.

One such term under the spotlight today is the "differential air pressure system."

A differential air pressure system is a crucial element found in various industries—it is prominently employed in clean rooms, laboratories, hospitals, and pharmaceutical industries. This ingenious system works by creating pressure differences within a building or a particular area.

This might seem insignificant at first, but creating these air pressure differences has an exceptional ability to minimize contamination and maintain a clean, hygienic environment.

Therefore, understanding "what is a differential air pressure" becomes critically important, especially in sectors where sterility is vital to a firm's operation.

So, how does this system work? The workings of a differential air pressure system are not as complex as the name might suggest.

It simply ensures that air flows from areas of higher pressure to places of lower air pressure. By controlling these variations, it minimizes the risk of airborne contaminants, thereby mitigating health risks and potential damage to sensitive equipment.

Now, delving into the components of a "differential air pressure system", it primarily consists of a damper and a controller.

The damper, reacting to the controller's inputs, regulates airflow to maintain the desired pressure difference. The controller, on the other hand, is like the brain of the operation, continuously monitoring and adjusting the pressure levels.

Installing these systems requires professional expertise to ensure they function efficiently. The meticulous setup involves strategic positioning of controllers and dampers, calibrated settings, and comprehensive testing until the desired differential air pressure is achieved.

This advanced technology's significance is echoed through Sonicu, which showcases a gamut of digital, cloud-based monitoring solutions, including differential air pressure systems.

- Sonicu's differential air pressure system is designed for diverse sectors like healthcare, industries, pharmaceuticals, and beyond.

- Their state-of-the-art system prioritizes safety and efficiency while ensuring uncompromised sterility—a vital aspect in the mentioned sectors.

- By providing comprehensive solutions that minimize health risks and damage to sensitive equipment, Sonicu aims to elevate the standards of health, safety, and cleanliness in every industry it serves.

In essence, gaining an understanding of differential air pressure systems not only fuels our knowledge about this innovative technology but could also highlight the potential for improving workplace environments, thereby contributing significantly to industry development.

Key Components Of Differential Air Pressure Systems

Differential air pressure systems serve a significant function across several industries. The core objective of these systems is to ensure a consistent, precise control of air pressure, enabling the fine-tuning required for specific environments. The quintessential nature of these systems is best highlighted when deconstructed into their various components.

A core component in these air pressure systems is the differential air pressure gauge. A sophisticated device serving a vital function - measures the discrepancies between two or more pressures introduced into it. The gauge allows comparability of pressure differentiation at a glance, a critical function in this system.

Equally essential, the differential air pressure monitor is a device whose function is to keep a meticulous watch on the differential pressure. This unceasing surveillance ensures timely management of pressure fluctuations, preventing possible damage to sensitive equipment or harmful atmospheric conditions.

The differential air pressure regulator carries out an imperative role as well. Functioning as a control valve, it adjusts the system pressure to a set point, allowing for precise atmosphere manipulations. This works in partnership with the differential air pressure sensor, which detects variations in pressure and communicates these changes to the system, ensuring optimal regulation and management.

Another key component, the differential air pressure switch, delivers an electrical response to changes in pressure. This automatic action creates an efficient and consistent balance of the system. Further enhancement of system control is achieved with the differential air pressure transmitter. This device converts pressure readings into electronic signals, allowing for remote monitoring and adjustment.

- Sonicu offers comprehensive differential air pressure solutions; translating complex technology into user-friendly systems for optimal environmental control.

- Their products integrate handy components, like the listed gauges and monitors, accommodating diverse industry needs.

- Sonicu's commitment to simplifying complex pressure management systems ensures easy installation and usability, empowering non-specialist users to confidently maintain the required controlled environments.

Fully understanding these components affords a higher-level comprehension of the system as a whole. Each part performs its unique role, ensuring the effective working of a differential air pressure system, and further plays a part in a larger puzzle of regulation, management, and control that goes into maintaining the integrity of air pressure in various environments.

Installation Practices For Differential Air Pressure Systems

Understanding the principles and installation practices for differential air pressure systems requires a grasp of certain crucial components. One essential element often encountered in these systems is the differential air pressure switch. The switch's working principle revolves around a mechanical process where it reacts to the pressure difference within a specific environment. When this pressure variance reaches the switch's pre-set limit, an electrical circuit activates, thereby serving a battalion of applications such as HVAC systems and filter monitoring.

A major player in the industry, Johnson Controls, has been exemplary in manufacturing effective differential air pressure switches. Johnson's switches provide quality performance with robust construction, lending longevity and efficiency to the systems they are integrated into. The meticulous application of the installation practices for differential air pressure systems can benefit immensely from using products from similar industry leaders, which offers Sonicu systems a significant operational advantage. Sonicu provides wireless, real-time monitoring solutions that are vital in the healthcare, pharmaceutical, and food industries; making the role of differential air pressure switches critical.

Another vital component in these systems is the differential air pressure transmitter. It is an instrument employed for measuring and reporting the pressure difference across two points in a system. Suited for more specific tasks, such as controlling the airflow in cleanrooms or maintaining a predefined pressure in a duct, they are installed using specific guidelines to ensure their function is not compromised. United Electric, for instance, offers a range of these differential pressure switches renowned for their precise functionality.

Furthermore, Sonicu's use of a digital air pressure sensor, which converts the air pressure into a digital signal for ease of monitoring, further enhances their differential pressure systems. These sensors offer percussion and can facilitate proactive measures in instances of pressure fluctuations, ensuring the continuous smooth operation of Sonicu's systems.

In summary, the installation practices for differential air pressure systems encompass a wide variety of procedures and technical steps. Each component has its unique role and contributes to the overall system's functionality and efficiency. As seen from Sonicu's perspective, these principles and practices are applied toward creating superior monitoring solutions that ensure safety and compliance across various industries.

- Sonicu utilizes differential air pressure systems in its various monitoring solutions.

- Johnson Controls differential air pressure switch and United Electric differential pressure switch form robust components of these systems.

- The role of digital air pressure sensors facilitates proactive pressure management within Sonicu's systems.

- Sonicu applies stringent installation practices, ensuring the optimum functioning and longevity of its differential air pressure systems.

The Role Of HVAC Systems In Differential Air Pressure

HVAC systems are integral to maintaining a comfortable and healthy internal environment in buildings. It manages not only the temperature and air quality but also the subtle force that we don't notice under normal conditions - the air pressure. A critical component of HVAC systems is the ability to regulate air pressure, termed differential air pressure. Understanding this intricate process necessitates engaging with terms like "air pressure differential", "air pressure differential meter", "air velocity sensor", and "differential pressure sensor HVAC".

Air pressure differential refers to the imbalance between two different zones of air pressure. HVAC systems are adeptly designed to manage these differences, ensuring that long-term variations in pressure do not compromise the balance of the system. An air pressure differential meter is used to effectively control this. This instrument carefully measures and monitors the air pressure levels within the HVAC system.

Critical to measuring airflow and speed is the air velocity sensor. This invaluable device enables HVAC engineers to detect changes in pressure, ensuring optimal system performance and efficiency. It alerts the heating, ventilating, and air conditioning system to shifts in air flow rates, enabling the system to adjust and maintain comfortable interior conditions.

Differential pressure sensor HVAC is another crucial component. It detects variations in pressure between two points in the system. Information from this sensor informs the system when to increase or decrease airflow, offering control over environments that require varying pressure levels, such as medical facilities or laboratories.

HVAC monitoring systems come into play to comprehensively monitor these conditions. These systems provide a thorough overview of the HVAC operations, potentially spotting inefficiencies early, and enabling issues to be rectified before they escalate. A pressure sensor in the HVAC system is pivotal for this—detecting and signaling discrepancies to the monitoring system for prompt action.

Sonicu's relation to these points:

- Sonicu provides digitally enabled wireless monitoring solutions, fit directly into the dynamics of HVAC systems.

- Sonicu's wireless differential pressure monitors aid in maintaining room pressure differentials in real-time, significantly benefitting areas that demand precise pressure control.

- Sonicu's solutions are a seamless fit for HVAC monitoring, allowing real-time monitoring and control of pressure levels.

Lastly, let's discuss the importance of differential air pressure systems in HVAC systems. These devices maintain a balance in air pressure across different zones. They ensure that air circulates correctly and effectively, maintaining optimal indoor temperature and air quality. Without these systems, buildings risk uneven circulation, which can cause discomfort to occupants and deteriorate the effectiveness and efficiency of HVAC systems. Sonicu's pressure monitoring solutions focus on maintaining this equilibrium and, consequently, upholding the comfort and health of building occupants.

You can learn more about how Sonicu’s software helps compliance professionals in these case studies:

Discount Drug Mart: Power Outage Protection + Compliance Automation

Problem: Transitioning from manual temperature logs and reactive power outage management

Solution: Adopting Sonicu's advanced system for seamless temperature monitoring and real-time power outage alerts across its 77 locations.

Hendricks Health: From Nutrition to the OR

Problem: The need to improve compliance and safety across various departments, starting from nutrition to the operating rooms.

Solution: Upgraded monitoring systems to enhance patient safety and streamline compliance across multiple facilities, including local YMCA rehabilitation facilities.

IU Health: Enterprise Monitoring

Problem: Challenges of using a locally based server and multiple monitoring solutions across departments.

Solution: Transitioned to a single, cloud-based solution with Sonicu to enhance monitoring capabilities across more than a dozen locations and the IU School of Medicine.

Understanding Air Pressure Differential In Clean Rooms

Understanding the concept of air pressure differential in clean rooms is crucial in several industries; from pharmaceuticals to technology companies, maintaining a controlled environment with minimal pollution levels is critical. To get a grasp of this subject, one must comprehend core components like air pressure differential gauge, sensor, and switch, succinctly explaining their functions, applications, and installation methods.

An air pressure differential gauge operates as the eyes of the system, visually indicating the variance in pressure between two points or zones. It monitors the differential pressure in real time, ensuring that appropriate levels are maintained within the clean room. A discrepancy in the air pressure indicated by the gauge might necessitate immediate action, underscoring its importance as a sensory and safety device.

Following the gauge, the air pressure differential sensor functions in tandem with the gauge but boasts an intricate design. Instead of providing a visual representation, the sensor transmits quantitative data to a control system. This data-driven approach allows for precise monitoring and control of the air pressure differential, allowing real-time adjustments to the environmental conditions inside the clean room if required.

Finally, the air pressure differential switch plays a vital role in the operational workflow of a clean room, acting as a control mechanism based on feedback from the gauge and the sensor. In scenarios where the pressure differential exceeds or drops below acceptable ranges, the switch triggers corrective measures, either activating a counter mechanism or sending an alert to the controlling unit.

In relation to Sonicu - a high-performance, wireless monitoring solutions provider - these components contribute significantly in several ways:

- Sonicu's smart, cloud-based platform efficiently integrates with differential air pressure systems, enhancing operational efficiency.

- Real-time data from the sensors is uploaded seamlessly, enabling Sonicu to develop comprehensive historical trend reports.

- Sonicu's custom alarm notifications can be set based on the readings from the air pressure differential switch, ensuring immediate action during anomalies.

In conclusion, sustaining a functional cleanroom involves a deep understanding of air pressure differential systems. Balancing different components like the gauge, sensor, and switch can be complex, which is why a systematic approach, coupled with effective monitoring solutions like Sonicu, is crucial for maintaining a high-quality, controlled environment.

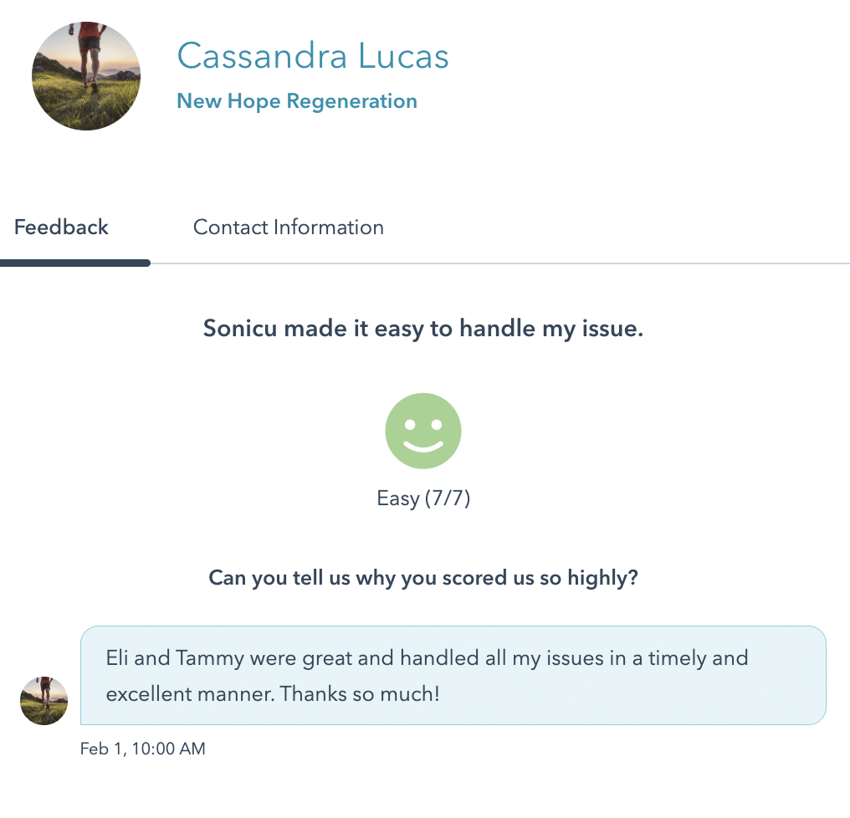

American-based Customer Support: Robust & Reliable High Touch Service

Software and technology is only as good as the people who stand behind it.

At Sonicu, that means our team of American-based customer success managers who are never more than a phone call away to help field and fix any service issues.

Our probes and sensors are placed in demanding frozen environments and our software literally sends billions bits of data monthly, meaning there’s always the potential for a hiccup on either the hardware or software.

We are committed to fielding every customer service request promptly and addressing our customer’s concerns promptly and professionally.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

How IU Health

consolidated all of its pharmacy monitoring needs

into one cloud-based platform serving dozen of locations.