Food Cooler Monitoring Technology

If you are looking for a food cooler monitoring technology that helps you and your team eliminate manual logging, improve compliance readiness, and protect all your temperature-sensitive assets, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts via text, email, push notifications and phone calls to protect your precious assets

- Compliance: Automated compliance reports

- Efficiency: Reduced Manual Logging and time spent on reports

- Robust Redundancy: Battery Backup and DataSync for reliable data continuity

And what makes us different?

- Lifetime Warranty: Ongoing warranty included with monitoring subscription

- Unlimited Users: Scale across your entire organization

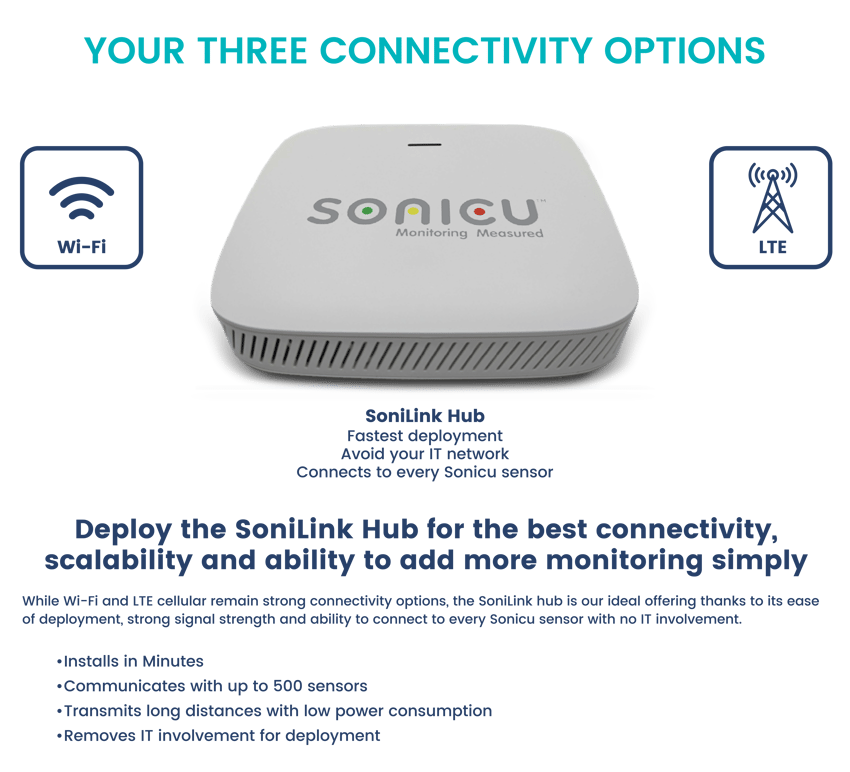

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

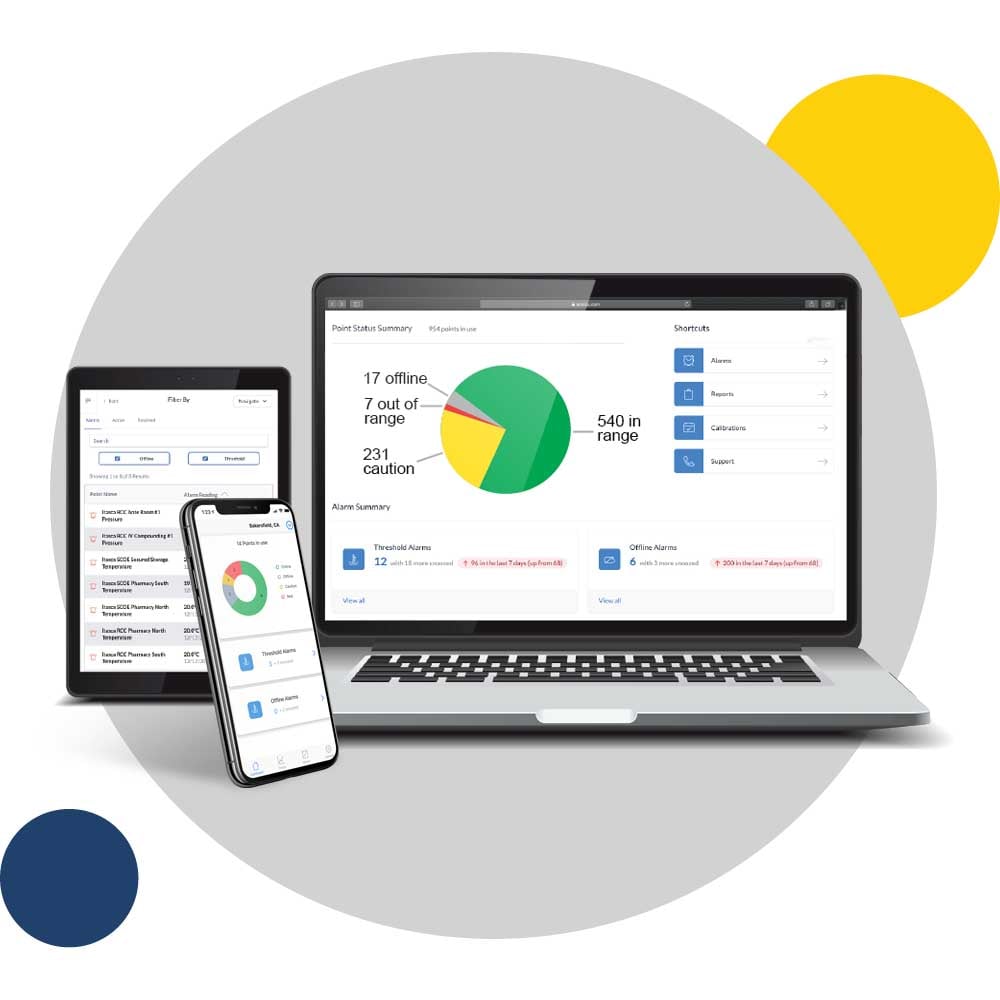

- Mobile App: 500 Freezers in your pocket

- Facility monitoring: Simple to add water leak, door open, occupancy, and even IAQ monitoring

Engineered in Indiana with U.S.-based support.

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

These respected healthcare and research brands turn to Sonicu for four primary reasons:

- Real-Time Monitoring: the sensors collect temperature, humidity, air pressure data and more, and transmit it wirelessly to SoniCloud - our cloud-based platform.

- Operational Efficiency: Virtually eliminate the need for tedious and costly manual logging

- Compliance Automation: Respond to any regulatory audit or inspection in a few clicks with our reports section

- Asset Protection: Detect and respond to any threshold that can threaten anything perishable: food, drugs, vaccines, research, etc.

.png?width=2000&height=312&name=Food%20Trust%20Bar%20Logos%20(2).png)

Cost competitiveness, great customer service, great control over the monitoring system, and low maintenance. You can't beat that.

Sonicu costs are considerably more reasonable than our historic system, as well as other competitors on the market. The equipment is robust but simple to learn and utilize.

Having safe and secure storage provides reassurance that any future family building efforts will be protected. Sonicu gave us the ability to more easily put our head on the pillows and sleep easier at night knowing we had invested in a strong monitoring system.”

Revolutionizing Food Safety: How Food Cooler Monitoring Technology is Changing the Game

Food cooler monitoring technology is an essential component in the management and operation of businesses dealing with perishable food items.

Food cooler monitoring technology involves systems and devices designed to track and regulate the temperature and humidity levels within food storage units such as refrigerators and freezers.

This technology typically includes:

- Sensors

- Devices that measure temperature and humidity levels within the cooler.

- Data loggers

- These record the temperature data over time.

- Alarms and alerts

- Systems that notify staff if temperatures deviate from set ranges.

- Remote monitoring

- Capability to monitor conditions remotely through internet-connected devices.

Food cooler monitoring technology is used in restaurants and cafes to ensure food is stored at safe temperatures to prevent spoilage and foodborne illnesses.

Supermarkets and grocery stores utilize this solution to monitor a wide range of products, from fresh produce to frozen goods.

In food processing and manufacturing, these monitoring systems help maintain specific temperatures for food safety and quality during processing and storage.

Catering services–especially those operating in outdoor or varying environments–leverage food cooler monitoring technology to uphold quality and safety.

In pharmaceuticals, storing food-related products, certain medications and supplements require strict temperature control similar to food products.

Food cooler monitoring technology is utilized for the cold chain management of food items during transit, and it also helps in complying with food safety regulations (like HACCP) by maintaining necessary temperature levels.

This solution reduces waste and financial loss by preventing spoilage.

It also allows staff to focus on other tasks while the system monitors the temperatures.

Additionally, it can provide a log of temperature data which can be crucial for health inspections and audits.

Food cooler monitoring technology ensures high standards of food quality, building trust with customers.

Smart systems can optimize energy use, reducing costs and environmental impact.

Thanks to remote monitoring,management can monitor conditions from anywhere, adding convenience and immediate response capability.

Food cooler monitoring technology is a vital tool for businesses in the food industry. It aids in maintaining food quality, ensures compliance with food safety standards, reduces waste, and enhances overall operational efficiency.

The implementation of this technology can have a significant positive impact on the smooth operation and profitability of food-related businesses.

What are the key components of food cooler monitoring technology?

Food cooler monitoring technology encompasses several components that work together to ensure the optimal preservation of perishable goods. This technology leverages a variety of technological advancements to perform its functions effectively.

- Temperature and humidity sensors

- These are the primary sensors used to monitor the internal conditions of the cooler.

- They continuously measure the temperature and, in some cases, the humidity levels to ensure they remain within safe and desired ranges.

- Utilize thermistors, thermocouples, or digital temperature sensors for accurate temperature readings.

- Humidity sensors are often capacitive or resistive types.

- Data loggers

- Data loggers record the temperature and humidity readings over time.

- They provide a historical record which can be crucial for audits and analyzing trends in cooler performance.

- Alarms and notifications

- These systems alert staff when temperatures or humidity levels fall outside of the predetermined safe range.

- Notifications can be sent through various channels, such as emails, text messages, calls or in-system alerts.

- IoT Connectivity

- Many modern systems are connected to the Internet (IoT - Internet of Things), allowing for remote monitoring.

- Integrates sensors and devices into a network, allowing for smart and automated control systems.

- This feature is particularly important for large operations or for businesses that need to monitor multiple locations.

- Wireless technology

- Wireless sensors and systems facilitate easier installation and flexibility in placement.

- They often use Wi-Fi, cellular, or Bluetooth technology to transmit data to a central monitoring system.

- Cloud computing and data storage

- Cloud-based platforms are often used for storing the vast amounts of data collected by these systems.

- They enable easier access to data, better scalability, and off-site backup for increased data security.

- Offer scalability and reliability in data handling.

- Energy management systems

- Some advanced cooler monitoring systems include energy management features.

- These systems optimize the power usage of the cooling units, reducing energy costs and environmental impact.

- Data analytics and AI

- Advanced systems may use artificial intelligence (AI) and machine learning algorithms to predict potential issues, optimize performance, and analyze trends.

- Help in making data-driven decisions for maintenance and operational efficiency.

- Mobile and web applications

- User interfaces for monitoring and control are often provided through web and mobile applications.

- Allow users to access data and receive alerts on the go.

Food cooler monitoring technology is a sophisticated integration of sensor technology, wireless communication, IoT capabilities, cloud computing, and in some cases, AI and data analytics. These components and technologies collectively ensure that food storage conditions are optimal, safe, and efficient, which is crucial for businesses that handle perishable goods.

You can learn more about how our software helps compliance professionals in these case studies:

Problem: Pharmacy Suffered Too Much Humidity In New Wing, impacting Compounding Pharmacy

Solution: Affordable Humidity Monitoring that Delivered Powerful data to prompt contractors to fix improperly sized air handler

Problem: Dining department struck with regulatory violations

Solution: Enterprise-wide monitoring that automates regulatory compliance across all departments

Problem: Release of lead particles in battery projects

Solution: Mobile, affordable air pressure monitoring solution

In addition to aiding cooler monitoring, Sonicu plays a vital role for organizations such as Ohio University in other industries including:

- Healthcare: Nurses respond to our alerts to keep your medicine safe

- Life Science/Lab: Lab directors rely on our alerts to protect priceless research

- Food Service: Food distributors rely on our tech to protect your dinner

What are the pain points in the food industry that food cooler technology addresses effectively?

Food cooler monitoring technology addresses several stubborn pain points in the food industry, significantly enhancing efficiency, safety, and compliance.

- Issue: Traditional methods of manual temperature checks are prone to human error, potentially leading to improper storage conditions.

- Solution: Automated monitoring ensures consistent, accurate temperature control, drastically reducing the risk of spoilage and foodborne illnesses.

- Issue: Regulatory bodies often require strict adherence to temperature control standards for food storage.

- Solution: Automated logging and reporting capabilities of these systems simplify compliance with health regulations like HACCP (Hazard Analysis Critical Control Points).

- Issue: Traditional coolers can consume significant energy, especially if not monitored or maintained properly.

- Solution: Smart monitoring systems can optimize cooling cycles, reducing energy consumption and costs.

- Issue: Inconsistent temperatures can lead to spoilage, resulting in significant food waste.

- Solution: Continuous monitoring minimizes spoilage, thereby reducing waste and associated costs.

- Issue: Manual monitoring is time-consuming and labor-intensive, diverting staff from other important tasks.

- Solution: Automated systems free up staff time, allowing them to focus on more productive activities.

- Issue: Without proper data, it's challenging to make informed decisions regarding inventory management and operational efficiencies.

- Solution: Cooler monitoring systems provide valuable data and analytics for better decision-making.

- Issue: Identifying a malfunction in cooling equipment can be delayed without continuous monitoring, leading to potential losses.

- Solution: Immediate alerts and notifications enable prompt response to equipment issues, preventing loss of stock.

- Issue: For businesses with multiple storage locations, ensuring uniform safety standards can be challenging.

- Solution: Remote monitoring capabilities allow centralized control and oversight of multiple sites.

- Issue: Fluctuations in temperature and humidity can affect the quality and shelf-life of food products.

- Solution: Constant monitoring ensures consistent storage conditions, maintaining product quality.

- Issue: Manual record-keeping is prone to errors and inefficiencies.

- Solution: Automated data logging provides accurate and easily accessible records for audits and inspections.

By addressing these challenges, food cooler monitoring technology not only enhances the operational efficiency of food businesses but also plays a critical role in ensuring food safety, regulatory compliance, and sustainability in the industry.

You can learn more about how our software helps compliance professionals in these case studies:

Problem: Needed to reduce time to complete HACCP compliance reports

Solution: Self-install of temperature monitoring for compliance automation

Problem: Needed pharmacy temperature monitoring following refrigerator loss across many remote clinics:

Solution: Simple Sonicu installation and configuration simplified standing-up remote systems

Indiana University Health: Enterprise Hospital For Temp, Humidity, Air Pressure

Problem: Server Based Monitoring lacking Enterprise Visibility

Solution: One Window into all monitoring across dozens of facilities

Companies such as Nomi Health have trusted Sonicu to provide them with peace of mind when it comes to temperature monitoring. Other benefits they receive by choosing Sonicu include:

- Asset Protection: Get alerts when a freezer is malfunctioning to protect assets like medicines, vaccines, blood, research, sperm/eggs

- Compliance Automation: Creates simple reports to satisfy local/state/federal regulations

- Operational Efficiency: Spend less time capturing data manually: Both temps/conditions and reporting

Key benefits of food cooler monitoring technology

- Consistent temperature monitoring reduces the risk of foodborne illnesses caused by improper storage conditions.

- Automated logging and real-time monitoring help in meeting strict food safety regulations and standards.

- By maintaining optimal storage conditions, the technology significantly lowers the chances of spoilage, thus reducing waste.

- Smart monitoring can optimize cooler operations, leading to lower energy consumption and cost savings.

- Immediate alerts for temperature fluctuations allow for prompt action, preventing potential losses.

- Automating temperature monitoring frees up staff to focus on other important tasks.

- Provides valuable insights for better inventory management and decision-making.

- Enables management of multiple locations from a central point, offering convenience and centralized control.

Embrace the Future with Sonicu: Elevating Standards in Food Safety and Efficiency

In the intricate dance of maintaining food safety and quality, the role of technology cannot be overstated. As we have explored, the advent of food cooler monitoring technology marks a significant leap in addressing the perennial challenges faced by the food industry. From ensuring compliance with stringent health regulations to dramatically reducing food spoilage, this technology stands as a guardian of both public health and business efficiency.

Sonicu's range of food cooler monitoring solutions epitomizes this technological evolution. By seamlessly blending accuracy, reliability, and user-friendliness, Sonicu not only promises peace of mind but also delivers a tangible impact on your bottom line. The advantages are clear: enhanced food safety, reduced waste, energy efficiency, and invaluable data insights, all culminating in a robust food storage management system.

However, we acknowledge the considerations that come with integrating new technology. Investment in such systems is not merely a purchase but a partnership in pursuing excellence in food safety and operational efficiency. With Sonicu, the transition is streamlined, and supported by an expert team dedicated to ensuring that your journey towards technological adaptation is as smooth as it is rewarding.

As we close this discussion, it is crucial to reflect on the broader impact of your choices. By adopting Sonicu's innovative solutions, you are not just upgrading your operations; you are contributing to a larger narrative of safety, quality, and sustainability in the food industry. The future beckons with the promise of smarter, safer, and more efficient food storage practices.

Are you ready to be a part of this transformative journey?

Embark on a path of innovation and excellence with Sonicu's food cooler monitoring technology. Safeguard your products, protect your customers, and elevate your business standards. Contact Sonicu today to learn more about how we can help you achieve improved food safety and quality.

Enhance Your Food Safety Standards with Sonicu – Your Partner in Excellence.

American-based Customer Support: Robust & Reliable High Touch Service

Software and technology is only as good as the people who stand behind it.

At Sonicu, that means our team of American-based customer success managers who are never more than a phone call away to help field and fix any service issues.

Our probes and sensors are placed in demanding frozen environments and our software literally sends billions bits of data monthly, meaning there’s always the potential for a hiccup on either the hardware or software.

We are committed to fielding every customer service request promptly and addressing our customer’s concerns promptly and professionally.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

The Sonicu Difference

Advanced Alarming

Cloud-based software capabilities with predictive algorithms for tailored alarming to reduce alarm fatigue and spot trends.

SMART Digital Sensors

SMART sensors with proprietary DataSync capture. Preserve and secure data in the event of transmission interruptions.

SMART Reporting

Automated logging and reporting unrivaled in the industry for effortless regulatory compliance.

Battery Backup

Industry leading battery life on all sensors. In the event of a power outage Sonicu's wireless sensors continue to keep you notified.

The Safest Network

Virtual Private Network on Verizon cellular platform that eliminates security concerns when transmitting data to the cloud.

Flexible Transmission

Replace server-based systems and eliminate IT concerns with a variety of transmission signals including: Cellular, Radio Frequency, WiFi, and Ethernet.

Recalibration is Easy

All-digital temperature probes for easy calibration renewal with Sonicu's SNAP calibration program.

Ensuring Consistency

Service quality and connectivity reports provide detailed analysis of system operations.

How IU Health

consolidated all of its pharmacy monitoring needs

into one cloud-based platform serving dozen of locations.