Food Manufacturing Cooler Monitoring Solutions

If you’re looking for a cloud-based air pressure monitoring sensor solution that eliminates manual logging, improves compliance readiness, manage the temperature and humidity levels in food manufacturing coolers, refrigerators, and freezers to ensure food safety and quality, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts via text, email, push notifications and phone calls to protect your precious assets

- Compliance: Automated compliance reports

- Efficiency: Reduced Manual Logging and time spent on reports

- Robust Redundancy: Battery Backup and DataSync for reliable data continuity

And what makes us different?

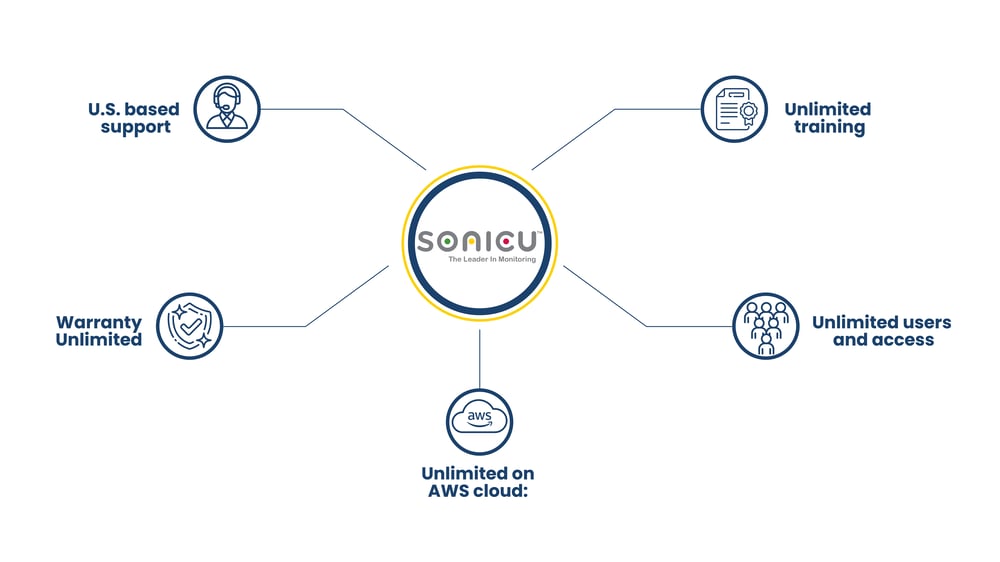

- Lifetime Warranty: Ongoing warranty included with monitoring subscription

- Unlimited Users: Scale across your entire organization

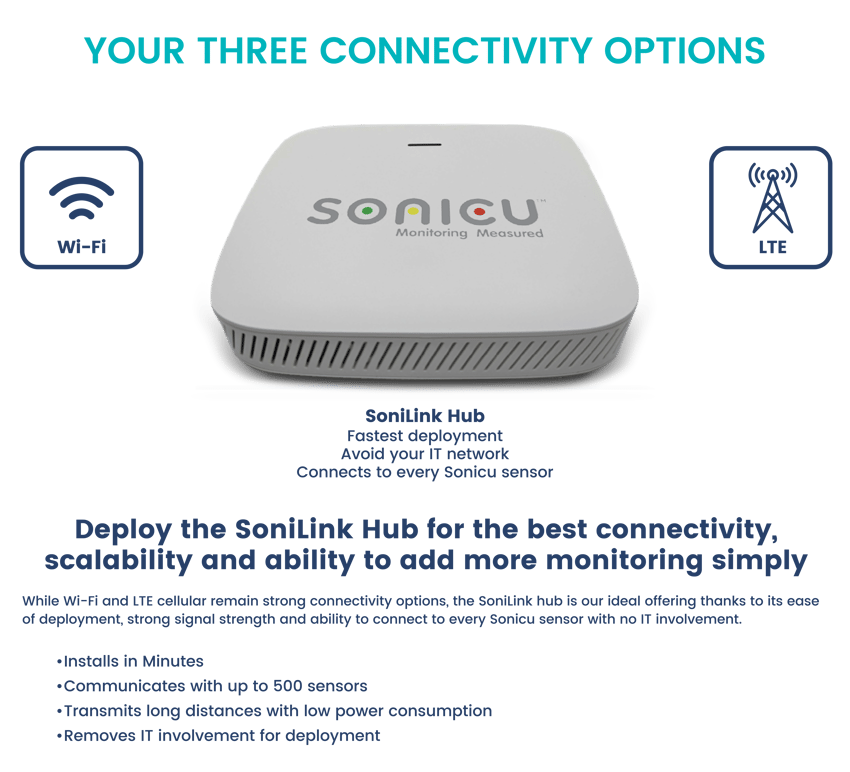

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

- Mobile App: 500 Freezers in your pocket

- Facility monitoring: Simple to add water leak, door open, occupancy, and even IAQ monitoring

Engineered in Indiana with U.S.-based support.

Sonicu costs are considerably more reasonable than our historic system, as well as other competitors on the market. The equipment is robust but simple to learn and utilize.

Having safe and secure storage provides reassurance that any future family building efforts will be protected. Sonicu gave us the ability to more easily put our head on the pillows and sleep easier at night knowing we had invested in a strong monitoring system.”

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

.png?width=2000&height=312&name=Food%20Trust%20Bar%20Logos%20(2).png)

Food Manufacturing Cooler Monitoring Solutions

Food manufacturing cooler monitoring solutions are systems that help to monitor and manage the temperature and humidity levels in food manufacturing coolers, refrigerators, and freezers.

In the food industry, it is critical to maintain proper temperature and humidity levels in coolers to ensure the safety and quality of the food being stored.

Temperature and humidity fluctuations can result in spoilage or bacterial growth, which may ultimately lead to foodborne diseases and product recalls.

A good food manufacturing cooler monitoring solution can help to avert all these issues by triggering alerts once temperature and humidity levels fall or rise beyond the acceptable range.

Also, virtually all food manufacturers are subject to a number of regulatory guidelines for temperature monitoring and control including the hazard analysis and critical control points (HACCP) protocols.

So making the smart choice to implement a monitoring solution can help guarantee continued compliance with such regulations. While at the same time, providing documentation of temperature and humidity levels for auditing purposes.

Thousands of food service, healthcare, and life science professionals rely on Sonicu for their temperature and humidity monitoring needs thanks to our affordability, simplicity of installation and onboarding, and robust U.S.-based live support.

We have many case studies that show how professionals from a diverse range of industries have automated their regulatory compliance, protected their perishable assets, and virtually eliminated their manual temperature logging processes with Sonicu.

Food Manufacturing Cooler Monitoring Solutions - Components

A food manufacturing cooler monitoring system comprises several different components that work seamlessly together to monitor and manage temperature and humidity levels in food coolers.

First, there are temperature and humidity sensors that work together to continuously measure, record and report on temperature and humidity conditions within the cooler.

Temperature sensors typically use a thermistor or thermocouple to take readings.

The first variety is a sort of resistor that can alter its resistance to correspond with changes in temperature.

A thermocouple, on its part, is a sensor that produces a voltage proportional to temperature differentials between two junctions. Both thermistors and thermocouples are used in temperature monitoring sensors to deliver accurate temperature readings in a food manufacturing cooler.

Conversely, humidity sensors take readings of the amount of moisture in the air.

Capacitive sensors are the most common solution for manufacturing cooler monitoring applications. They work by measuring changes in the dielectric constant of a material as it corresponds to humidity changes.

Sonicu normally provides temperature and environmental monitoring kits that contain all the elements required to establish a monitoring system, including sensors and communicating Duo meters.

Temperature and humidity sensors may be wired or wireless.

The first are connected to a monitoring system via cables to deliver measurements. Wireless sensors utilize radio waves or other wireless communication protocols to transmit data to the monitoring system like Wi-Fi, Bluetooth, or Zigbee.

Sonicu features the communicating Duo meter which has the flexibility to transmit the monitoring data with either Wi-Fi, cellular, or via LoRaWAN, which is a radio frequency used specifically for the Internet of Things.

This Technical Overview shows in greater detail the communication protocols and how they can be leveraged to increase flexibility and ease of installation while virtually eliminating the need for IT support or even the use of your network.

Besides the temperature and humidity sensors, the other essential component of a food manufacturing cooler monitoring system is the monitoring software.

It works by receiving and processing the data transmitted by the sensors. This software might be cloud-based or installed locally on a computer.

It is usually configured to send alerts when temperature or humidity levels in a cooler fall or rise beyond the acceptable range. These alerts may be dispatched via email, text message, or any other notification method the user chooses.

You can learn more about how our software helps compliance professionals in these case studies:

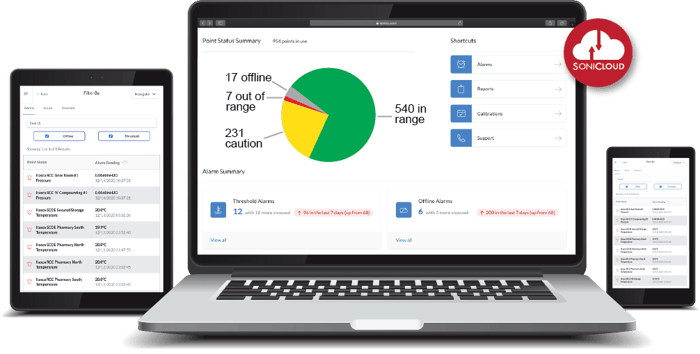

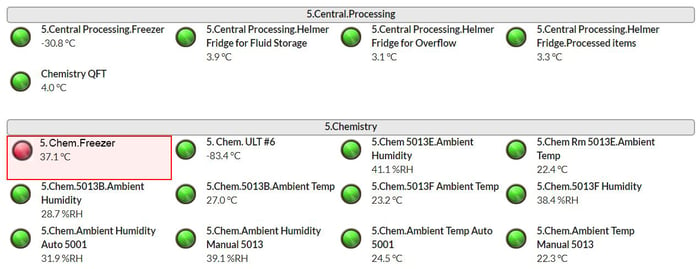

SoniCloud is the cloud-based software available on any web-connected device. Engineered based on customer input from dozens of healthcare, life science, and food service professionals who require a simple platform to set up alarms, automate their reporting, and share real-time views of their assets and environments from a single dashboard.

The mobile app version of SoniCloud includes an Installation Wizard that walks new users step-by-step through the connectivity and configuration process, resulting in an average installation time of about 20 minutes per cold/frozen storage monitoring device.

Cryopoint: Mission-Critical Monitoring

Problem: Cryopoint faced calibration challenges with their legacy monitoring system and issues with a server-based system, putting critical samples at risk.

Solution: Transitioned to Sonicu's SoniCloud and its mobile-first solution, enhancing reliability in monitoring and easing operations.

Ohio University Innovation Center

Problem: Tech and tech-enabled startups at the Innovation Center needed reliable support systems for temperature and environmental monitoring due to the requirements of grant-funded projects.

Solution: Implement Sonicu for comprehensive monitoring of temperature, ambient humidity, and air pressure differential, ensuring necessary protection and compliance.

Hancock Regional Health: Enterprise Monitoring from Sound to Environmental

Problem: Disparate monitoring systems were taxing the staff with many manual processes, leading to inefficiencies and reduced asset protection.

Solution: CEO Steve Long initiated the adoption of a consolidated monitoring program for temperature, environmental, and sound, which automated compliance and reduced manual logging.

Installation Video: Easy install for your cold storage monitoring

Cloud-based Food Manufacturing Cooler Monitoring Solutions

Otherwise known as wireless or IoT sensors, cloud-based food manufacturing cooler monitoring systems are designed to transmit temperature and humidity readings to a cloud-based software platform, leveraging wireless communication protocols including Wi-Fi and cellular networks.

Cloud-based temperature and humidity monitoring sensors are noted for delivering a number of advantages upon comparison with traditional wired systems.

One of the most prominent of which is they may be effortlessly and conveniently installed in a food manufacturing cooler without needing additional IT infrastructure like gateways or routers.

About half of Sonicu customers install their own systems and then configure their reports and alerts with the support of a dedicated Customer Success Manager who ensures their system is built to their specific requirements.

In turn, this makes this temperature and humidity monitoring solution an excellent choice for remote or hard-to-reach areas where the more traditional sensors might not be practical.

Another plus for settling for cloud-based solutions like Sonicu is they offer real-time data monitoring and reporting capabilities.

This allows food manufacturers to rapidly determine issues with temperature or humidity levels in their coolers and take corrective action.

Our robust alarm handler makes it easy for system admins to build, edit and grow alarm notification trees that ensure a temperature and/or environmental excursion is responded to promptly.

Additionally, cloud-based systems can offer advanced analytics functionalities that will deliver insights into temperature and humidity trends over time. This enables food manufacturers to optimize their cooler management processes to reduce the risk of food spoilage or contamination and to ensure continued compliance with regulations.

Lastly, cloud-based sensors may be easily integrated into other IoT devices and software platforms.

For instance, a temperature and humidity sensor may be seamlessly integrated with a cloud-based Building Automation System that can push data to a facility manager or can pull data from a BMS/BAS into the Sonicu system to take advantage of the alerts and reports.

Sonicu conducted a webinar with the Controls Group North America that showcased how to use this wireless connectivity between our monitoring platform and your BMS system which illustrates the value and simplicity of the integration.

Comparisons of Food Manufacturing Cooler Monitoring Solutions

As it has been earlier mentioned, both cloud-based sensors and traditional data loggers are utilized to monitor temperature and humidity levels within food manufacturing coolers.

Data loggers are standalone devices that are battery-powered and work by taking temperature and humidity readings at set intervals.

These readings are usually stored locally on the device and must be manually retrieved and downloaded to a computer for analysis.

Some data loggers come with basic alarm functionalities that can alert users when temperature or humidity readings deviate from the acceptable range. However, very few of them can provide real-time monitoring or remote data access.

On the other hand, cloud-based food manufacturing cooler monitoring solutions can deliver real-time data monitoring and remote access to data via a software platform.

Data is transmitted wirelessly from the sensors to the cloud-based platform where authorized users can access it with any internet-enabled device.

Yet another key difference between data loggers and cloud-based sensors is the ease of installation and use.

Traditional data loggers can be difficult to install and often require manual retrieval and downloading of the data stored in them. This can prove to be both a time-consuming and labor-intensive process.

Alternatively, cloud-based sensors are easy and convenient to install and may be effortlessly accessed and managed remotely, which saves time and minimizes the risk of errors.

Affordable and Reliable Food Manufacturing Cooler Monitoring System

Affordability is yet another key difference between cloud-based food manufacturing cooler monitoring solutions and other options including data loggers.

Typically, the price of data loggers varies from a few hundred dollars to several thousand dollars depending on the device type and its features.

Besides the cost of the data logger itself, there might be hidden costs associated with data retrieval like the cost of shipping the device to its maker and the cost of software to download and analyze its data.

Conversely, cloud-based solutions generally come with a higher upfront cost for the hardware and software. However, they always prove to be the most cost-effective option in the long-term.

These temperature and humidity monitoring systems eliminate the need for manual data retrieval and analysis.

In turn, this not only saves valuable time, but reduces labor costs.

Also, by providing real-time monitoring and remote access features, they can help avert costly product losses attributable to temperature or humidity issues.

Additionally, cloud-based sensors are much more scalable than data loggers, which may be an important consideration for larger food manufacturing enterprises.

Traditional data loggers require multiple devices to be able to effectively monitor different areas within a food manufacturing facility. Alternatively, cloud-based sensors are often added or repositioned whenever necessary simply.

The onboard battery and data storage of the Sonicu Duo communicating meter make it ideal if you need to move the device temporarily or even install it in a location without power or even Wi-Fi connectivity.

At the same time, since they offer remote access to data from anywhere where there is an internet connection, these solutions eliminate the need for staff to be physically present at the facility in order to access and analyze data.

In turn, this can reduce travel costs and improve overall efficiency.

Lastly, these sensors may be integrated with other systems including inventory management, quality control, and production planning tools.

This can lead to increased efficiencies and significant cost savings in these areas.

Cloud-based food manufacturing cooler monitoring systems deliver a comprehensive temperature and humidity monitoring solution and provide substantial cost savings and efficiencies in several areas of a food manufacturing business.

While they may be a larger investment initially, the long-term benefits they offer make them a more cost-effective option over time.

You can learn more about how our software helps compliance professionals in these case studies:

Nomi Health: Fast installation, simple deployment

Problem: A rapidly growing healthcare technology startup needed to scale quickly and monitor cold chain storage devices nationwide.

Solution: Implement Sonicu's temperature probes with a central command center for enterprise visibility, allowing fast and easy training for reps across the country.

CleanSlate: Addiction Treatment Centers

Problem: A Boston-based addiction treatment center needed an affordable and simple monitoring solution for their facilities across the United States.

Solution: Choose Sonicu for its affordability and ease of self-installation, supporting the center's mission to manage growth and improve service delivery nationwide.

UHS: South Texas Health System, Edinburg

Problem: Fire alarm testing disrupted the environmental conditions in Operating Rooms, causing compliance and operational challenges.

Solution: Implemented Sonicu's environmental monitoring system, which allowed the facility manager to monitor conditions via a mobile app and resolve issues with the HVAC system triggered by fire alarms.

Conclusion

Food manufacturing cooler monitoring solutions not only help ensure food safety and quality, but guarantee continued compliance with regulations in the food industry.

Federal, state, and local regulators make temperature integrity a critical part of virtually any inspection related to food safety from manufacturing through distribution and onto the retail location.

There are many temperature monitoring sensors available in the market, but investing in a Sonicu system will deliver many essential characteristics, including

- Affordability: Far less costly than many enterprise solutions

- Simplicity: From installation and configuration to usage and support

- Easy to scale across an organization

These systems not only eliminate manual processes, but also provide real-time alerts and data logging capabilities for analytics and reporting.

While, at the same time, streamlining workflows and improving efficiency.

Why Automated Monitoring:

Hospitals have pharmaceuticals, vaccines, and other temperature-sensitive assets needing protection.

These assets becoming too hot or cold can cost thousands and put patients at risk.

Regulatory agencies require many departments to maintain records of temperature, humidity, and other settings throughout the hospital.

This can add stress and tie up staff resources.

Current Methods

Today, many facilities rely heavily on manual processes to maintain records and ensure compliance. This method can be labor-intensive and error-prone.

Data-Loggers are prevalent but still require someone to visit each storage area every day.

Loggers assist with compliance but rarely identify problems until it’s too late.

Sonicu Solution

Sonicu’s solution is a fully scalable, cloud-based solution that automates your monitoring processes across all departments. With 24/7/365 continuous monitoring, we help you:

- Protect Valuable Assets with instantaneous, customizable, and actionable alerts sent via phone, email, text, or pager.

- Improve Operational Efficiency by eliminating manual monitoring and paper logs

- Adhere to Regulatory and Compliance requirements by providing unlimited data storage, timely reporting, and NIST management.

What We Offer

Sonicu provides monitoring for

- Temperature

- Humidity

- Sound

- Pressure

- Power

- and a host of other monitoring needs

Our flexible sensors can transmit data via

- Wi-Fi

- 900 MHz,

- or Cellular

SoniCloud software platform provides alarm handling, real-time and historical data views, and advanced algorithms to detect and alert potential equipment failure.

We help you stay compliant with

- Joint Commission

- VFC

- CDC

- USP

- FDA

- and other state and federal regulatory agencies

Our remote, wireless system provides 24/7/365 monitoring at desired intervals.

Each probe comes with a NIST certificate of traceability and is ISO-compliant.

Our re-calibration program easily and cost-effectively keeps you compliant for years to come.

American-based Customer Support: Robust & Reliable High Touch Service

Software and technology is only as good as the people who stand behind it.

At Sonicu, that means our team of American-based customer success managers who are never more than a phone call away to help field and fix any service issues.

Our probes and sensors are placed in demanding frozen environments and our software literally sends billions bits of data monthly, meaning there’s always the potential for a hiccup on either the hardware or software.

We are committed to fielding every customer service request promptly and addressing our customer’s concerns promptly and professionally.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

Cost competitiveness, great customer service, great control over the monitoring system, and low maintenance. You can't beat that.