Food Manufacturing Cooler Monitoring Systems

If you are looking for a food manufacturing cooler monitoring system that helps you and your team eliminate manual logging, improve compliance readiness, and protect all your temperature-sensitive assets, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts via text, email, push notifications and phone calls to protect your precious assets

- Compliance: Automated compliance reports

- Efficiency: Reduced Manual Logging and time spent on reports

- Robust Redundancy: Battery Backup and DataSync for reliable data continuity

And what makes us different?

- Lifetime Warranty: Ongoing warranty included with monitoring subscription

- Unlimited Users: Scale across your entire organization

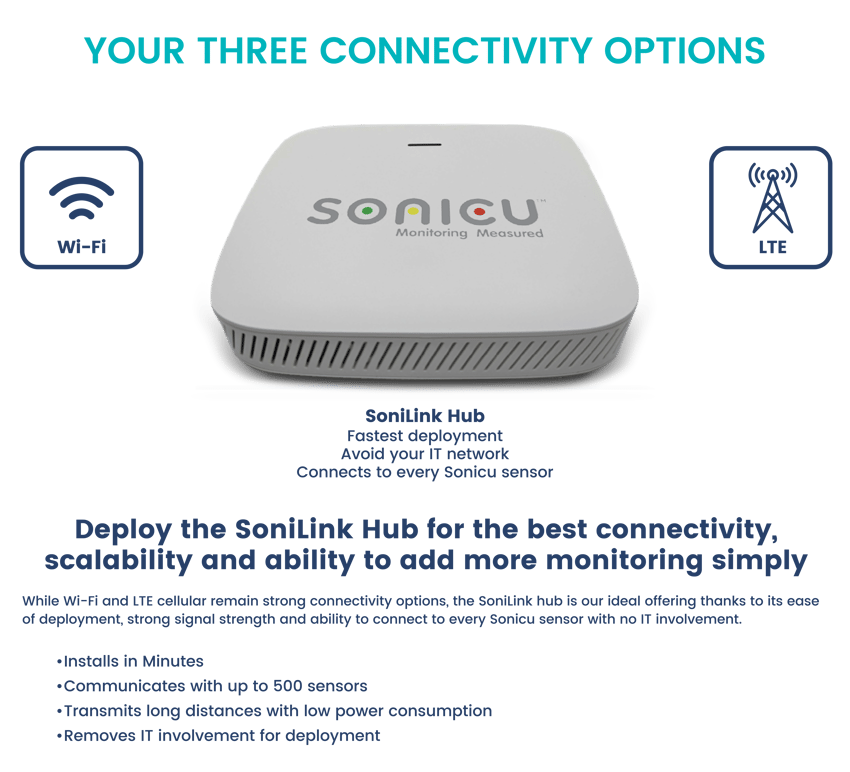

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

- Mobile App: 500 Freezers in your pocket

- Facility monitoring: Simple to add water leak, door open, occupancy, and even IAQ monitoring

Engineered in Indiana with U.S.-based support.

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

Food Manufacturing Cooler Monitoring Systems

Some of the finest names in healthcare, including Indiana University Health, University of Michigan Health System, and Stanford University rely on Sonicu to provide a robust and continuous environmental monitoring system, including temperature, humidity, air pressure, and more.

These respected healthcare and research brands turn to Sonicu for four primary reasons:

- Real-Time Monitoring: the sensors collect temperature, humidity, air pressure data, and more, and transmit it wirelessly to SoniCloud - our cloud-based platform.

- Operational Efficiency: Virtually eliminate the need for tedious and costly manual logging

- Compliance Automation: Respond to any regulatory audit or inspection in a few clicks with our reports section

- Asset Protection: Detect and respond to any threshold that can threaten anything perishable: food, drugs, vaccines, research, etc.

Our customers stay with us thanks to our American-based customer support, which is never more than a phone call away. While our technology is intuitive and powerful, we know it’s only as strong as the people who stand behind it.

Food manufacturing cooler monitoring systems are pivotal in ensuring the optimum functionality of a food production line.

This state-of-the-art tool plays a significant role in maintaining the safety and quality of food products, as fluctuating temperatures can lead to spoilage and potentially harmful bacteria.

These systems offer an integrated approach to cooler monitoring, incorporating sensors to record temperatures, humidity and other crucial variables in the cooler environment.

Industrial temperature monitoring systems are a vital component of these cooler monitoring systems. They help keep the food fresh and optimal for consumption while meeting stringent health and safety standards.

With the constant real-time tracking of temperature fluctuations, every product can be stored in its ideal environment for extended shelf life.

The collected data can be analyzed to optimize cooling processes, ultimately leading to saved costs and less food waste.

Sonicu's industrial temperature monitoring solutions provide comprehensive, real-time visibility into the environmental conditions of your production facility, ensuring consistent product quality and compliance with food safety regulations.

Next, refrigeration monitoring and control system is another key piece of the cooling monitoring systems puzzle.

These innovative systems allow food manufacturers to remotely access all their fridge units in real-time, improving operational efficiency and ensuring swift responses to any issues that may arise.

Sonicu's digitized wireless sensors facilitate remote refrigeration monitoring, thus empowering faster decision-making processes and significantly decreasing the chances of food spoilage due to equipment malfunction or power outages.

By centralizing control, these systems reduce operational costs and increase efficiency.

Therefore, investing in a robust food manufacturing cooler monitoring system such as those provided bySonicu is a sure-fire way to protect against costly food spoilage, reduce operational costs, and ensure compliant, safe food production.

The benefits are undeniable, making the system an integral part of the modern food manufacturing industry.

Exploring The Best Food Manufacturing Cooler Monitoring Systems

Exploring the best food manufacturing cooler monitoring systems is no trivial pursuit. Ensuring efficiency, cost-effectiveness, and optimal performance become pivotal in this quest.

The concept of commercial refrigeration monitoring systems moves past simply storing products at ideal temperatures; it involves precise monitoring and immediate alert systems to prevent unnecessary product spoilage, ensuring unwavering quality control while enhancing operational efficiency.

Among the many available options, certain systems stand out due to their exceptional performance and superior features.

For instance, the well-renowned Sonicu, a pioneer within the industry, provides comprehensive solutions offering around-the-clock temperature monitoring and data logging, ensuring constant product surveillance, though Sonicu is not the only provider offering high-quality monitoring systems.

Some of the best commercial refrigeration monitoring systems have been engineered with a focus on efficiency and reliability.

These systems offer advanced features such as customizable alerts, trend analysis, data analytics, and remote access to monitor temperatures, humidity, and energy usage.

The seamless integration of these features in top-notch monitoring systems demonstrates technology's significant role in the food manufacturing industry.

When selecting the best food manufacturing cooler monitoring systems, many factors come into play.

From performance and compatibility to cost and reliability, each is substantial. Optimum systems integrate performance and cost-effectiveness, presenting a solid investment that offers substantial returns.

Sonicu's wide-ranging monitoring capabilities present real-time data and alerts, further allowing remote viewing of temperatures through their cloud-based platform.

High-tech predictive analytics and trend mapping prevent potential problems before they even occur, ensuring consistent product quality.

Sonicu's adherence to federal and state compliance standards ensures year-round regulatory compliance, securing peace of mind for companies in this industry.

Offering a cost-efficient solution, Sonicu amalgamates performance and affordability, proving once again why they stand at the industry's forefront.

In summary, the pursuit of exploring the best food manufacturing cooler monitoring systems is a rewarding balance act, harmonizing performance, cost, compatibility, usability, and regulatory compliance.

With innovative technologies like Sonicu leading the charge, the industry continues to thrive.

The Cost Of Cooler Monitoring Systems

The retail industry is characterized by constant transformation, with businesses continually striving to enhance operational efficiency and customer service.

One crucial facet within this context is the food manufacturing process, particularly, its reliance on commercial refrigeration systems.

An essential part of these systems is cooler monitoring, a niche technology that, in recent times, has steadily gained prominence.

The relevance of cooler monitoring systems, however, extends beyond food manufacturing, garnering a substantial footprint within the commercial domain.

The term "the cost of cooler monitoring systems" may appear daunting to some, as it suggests a hefty investment.

However, the cost should be viewed from an extensive lens, bearing in mind long-term savings versus initial capital outlay.

Further, the benefits empowered by monitoring systems make it an indispensable investment, offering unprecedented control over the preservation quality of perishables.

- The cost of cooler monitoring systems varies, but Sonicu offers robust and cost-effective solutions designed to provide maximum value with minimal investment.

- Sonicu's commercial refrigeration monitoring systems cost is designed to be affordable, promising a high return-on-investment through prevention of food spoilage and improving food safety.

- Sonicu takes into account varying needs and budgets. Therefore, the food manufacturing cooler monitoring systems cost is flexible, with customizable options available to suit different business demands.

In summary, cooling systems play an instrumental role in the food manufacturing industry, and their successful operation hinges in large part on effective monitoring.

The commercial refrigeration monitoring systems cost is an investment that pays off handsomely in the long run, given its role in safeguarding precious inventories and improving operational efficiency.

It is indeed, a valuable tool that businesses cannot afford to overlook in today's competitive climate.

Sonicu stands at the forefront as a provider of superior, cost-effective monitoring solutions that are designed to deliver on all counts – efficiency, reliability, and value for money.

Commercial And Restaurant Usage Of Temperature Monitoring Systems

In today's world of rigorous food safety regulations, commercial and restaurant usage of temperature monitoring systems has become an essential part of operations.

These systems are designed to maintain optimal temperatures, ensuring food quality and safety in accordance with Hazard Analysis Critical Control Points (HACCP) monitoring procedures.

For instance, Sonicu, a leading provider of monitoring solutions, offers a range of sophisticated temperature monitoring systems that ensure adherence to strict food safety protocols.

Commercial refrigeration monitoring systems are a key component of HACCP procedures for food safety.

They diligently track temperature fluctuations in refrigeration units, negating risks associated with improper storage conditions.

The increased automation of these systems reduces manual oversight and prevents human errors, contributing to superior food safety.

Sonicu’s wireless monitoring and alarming technology, designed with leading-edge technology, ensure efficiency and reliability in commercial refrigeration monitoring systems.

Restaurants also significantly benefit from temperature monitoring systems.

Monitoring temperatures in refrigerators, freezers, and cooking units, these systems ensure restaurant meals meet the necessary food safety standards.

They provide an additional layer of protection against foodborne illnesses caused by insufficient temperature control.

Sonicu’s solutions aid in maintaining this control with real-time data access allowing for immediate response to potential discrepancies.

HACCP monitoring systems have been pivotal in ensuring safety in food services. A prime example of monitoring procedures from HACCP includes critically controlling temperature at various process points to mitigate food safety risks.

Sonicu’s robust cloud-based platform provides efficient HACCP-compliant solutions, thus fostering a comprehensive approach to food safety.

In summary, commercial refrigeration monitoring systems and restaurant temperature monitoring systems are fundamental to maintaining the quality and safety of food.

Sonicu, with its industry-leading technologies, provides competent solutions to meet varied needs in the food service sector.

Sonicu's wireless monitoring systems are a crucial tool in commercial refrigeration, ensuring optimal food storage conditions.

In restaurants, Sonicu technology mitigates food safety risks by providing real-time data for immediate response.

With HACCP compliant solutions on a robust cloud-based platform, Sonicu allows for a comprehensive and efficient approach to food safety.

Other Types Of Monitoring Systems And Their Uses

In the modern era of technological advancement, the Internet of Things (IoT) has revolutionized industries worldwide, with the development of various monitoring systems being a prominent part of this trend.

These systems include but are not limited to continuous parametric monitoring systems, data centre environmental monitoring systems, and pharmaceutical temperature monitoring systems.

Continuous parametric monitoring systems comprise smart sensors, virtual meters, and software applications that provide real-time tracking and analysis of a wide array of parameters, like temperature, humidity, and pressure.

These systems are chiefly used in industries where instant tracking and analysis of each stage in the manufacturing process is pivotal.

Sonicu emphasizes the versatility of these systems by adapting their technologies towards sectors like healthcare and pharmaceutical, where constant monitoring is synonymous with ensuring safety and efficacy.

Data center environmental monitoring systems are indispensable in the technological sectors.

They monitor and maintain optimal conditions in data centers and server rooms, essential for preventing data loss, equipment damage, and system failure.

Humidity or temperature fluctuations could be catastrophic, potentially leading to costly downtime.

Sonicu further fortifies their technology with exceptional alert systems and 24/7 monitoring capabilities, enhancing reliability in high-risk environments.

Pharmaceutical temperature monitoring systems, on the other hand, are vital for regulating temperatures in pharmaceutical companies.

Improper climate control can compromise the integrity of drugs and vaccines, rendering them ineffective or unsafe.

Sonicu recognizes the importance of this aspect and hence provides digital cloud-based solutions that ensure appropriate conditions for pharmaceutical products during storage and transportation.

Sonicu's continuous parametric monitoring systems cater to industries requiring instant monitoring in real-time.

Sonicu's data centre environmental monitoring systems maintain optimal conditions, precluding the risks of data loss and equipment damage.

With Sonicu's pharmaceutical temperature monitoring systems, the integrity of pharmaceutical products is maintained through stringent temperature control.

These examples emphasise Sonicu's technological prowess in providing effective monitoring solutions across various sectors.

In summary, monitoring systems are indispensable in the modern era, transcending industries and ensuring operational efficiency, safety, and integrity.

American-based Customer Support: Robust & Reliable High Touch Service

Software and technology is only as good as the people who stand behind it.

At Sonicu, that means our team of American-based customer success managers who are never more than a phone call away to help field and fix any service issues.

Our probes and sensors are placed in demanding frozen environments and our software literally sends billions bits of data monthly, meaning there’s always the potential for a hiccup on either the hardware or software.

We are committed to fielding every customer service request promptly and addressing our customer’s concerns promptly and professionally.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

How IU Health

consolidated all of its pharmacy monitoring needs

into one cloud-based platform serving dozen of locations.