Food Manufacturing Cooler Monitoring Technology

If you are looking for food manufacturing cooler monitoring technology that helps you and your team eliminate manual logging, improve compliance readiness, and protect all your temperature-sensitive assets, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts via text, email, push notifications and phone calls to protect your precious assets

- Compliance: Automated compliance reports

- Efficiency: Reduced Manual Logging and time spent on reports

- Robust Redundancy: Battery Backup and DataSync for reliable data continuity

And what makes us different?

- Lifetime Warranty: Ongoing warranty included with monitoring subscription

- Unlimited Users: Scale across your entire organization

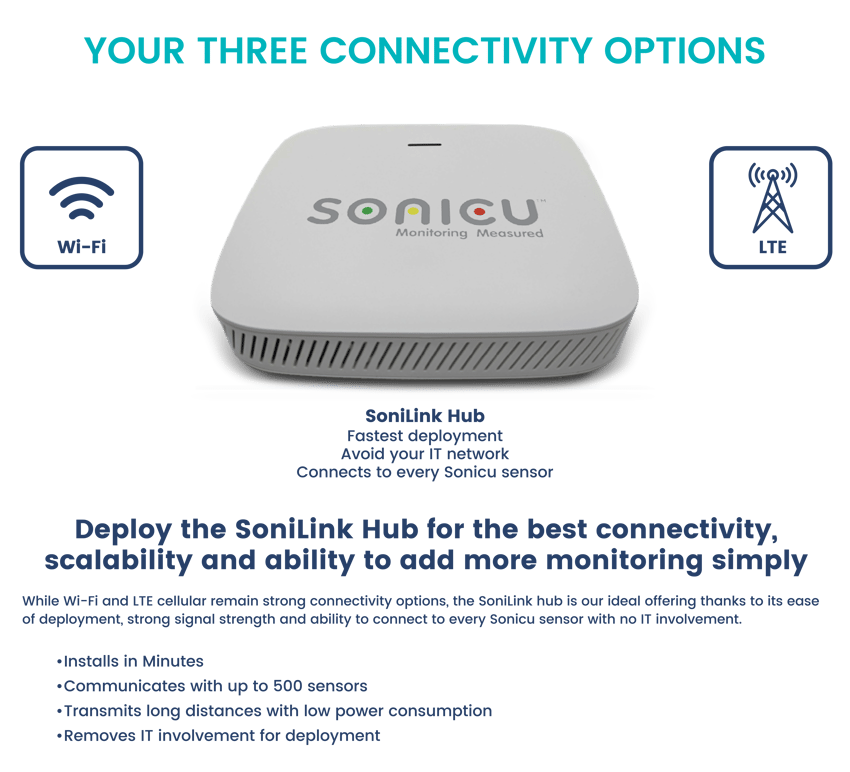

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

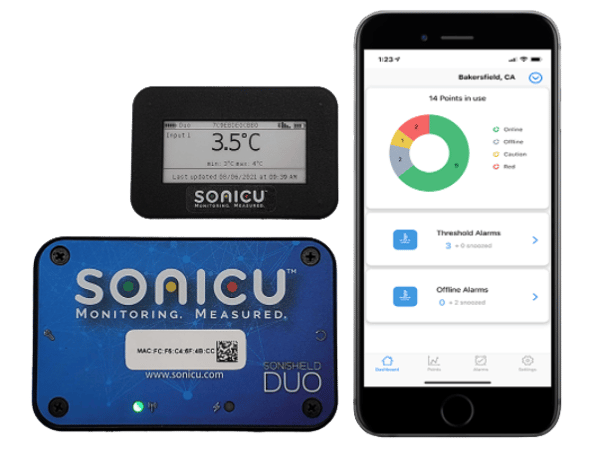

- Mobile App: 500 Freezers in your pocket

- Facility monitoring: Simple to add water leak, door open, occupancy, and even IAQ monitoring

Engineered in Indiana with U.S.-based support.

Before Sonicu, we had to don bunny suits to check the status of our cleanrooms. Now we check our phones and know right away. The system saves us time and effort and helps us respond to environmental

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

Some of the finest names in healthcare, including Indiana University Health, University of Michigan Health System, and Stanford University rely on Sonicu to provide a robust and continuous environmental monitoring system, including temperature, humidity, air pressure and more.

These respected healthcare and research brands turn to Sonicu for four primary reasons:

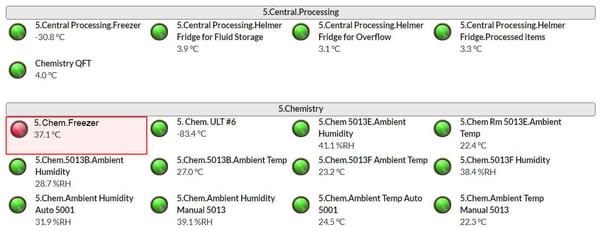

- Real-Time Monitoring: the sensors collect temperature, humidity, air pressure data and more, and transmit it wirelessly to SoniCloud - our cloud-based platform.

- Operational Efficiency: Virtually eliminate the need for tedious and costly manual logging

- Compliance Automation: Respond to any regulatory audit or inspection in a few clicks with our reports section

- Asset Protection: Detect and respond to any threshold that can threaten anything perishable: food, drugs, vaccines, research, etc.

Our customers stay with us thanks to our American-based customer support, which is never more than a phone call away. While our technology is intuitive and powerful, we know it’s only as strong as the people who stand behind it.

Food Manufacturing Cooler Monitoring Technology

Sonicu’s food manufacturing cooler monitoring eliminates manual logging, improves compliance readiness, and protects temperature-sensitive assets.

In the food industry, temperature is everything. Controlling climate, humidity, and air pressure in rooms, freezers, and coolers prevents spoilage and contamination of perishable items.

Sonicu’s food manufacturing cooler monitoring technology is a wireless, cloud-based solution designed with public health, efficiency, and compliance in mind.

While asset protection is vital in the food production industry for cost savings, food safety is a priority for health and safety. Compliance with the Food and Drug Administration promotes public health by meeting food safety and temperature control regulations.

The FDA’s Code of Federal Regulations Title 21 requires that refrigerated foods be maintained at 45 deg.F (7.2 deg.C) or below as appropriate for the particular food involved, frozen foods be maintained in a frozen state, and hot foods be maintained at 140 deg.F (60 deg.C) or above.

So monitoring food manufacturing coolers is crucial for maintaining food safety, quality, and regulatory compliance. Continuous monitoring helps ensure that the temperature and other environmental conditions within the coolers are within safe limits. This prevents the growth of harmful bacteria and preserves the freshness of the food products.

Maintaining proper temperature conditions is essential for preventing the growth of pathogenic microorganisms that can cause foodborne illnesses. Cooling units that store perishable foods such as raw meats, dairy products, and cooked dishes need to be monitored to ensure they stay within safe temperature ranges.

Also, many countries have strict regulations and guidelines for food safety and storage. Regular monitoring of cooler conditions helps food manufacturers meet these requirements and avoid penalties or legal issues.

Temperature fluctuations can also lead to changes in food texture, flavor, and appearance. Monitoring ensures that products maintain their intended quality, which is crucial for consumer satisfaction and brand reputation.

Proper cooling can significantly extend the shelf life and taste of perishable goods. Monitoring conditions in coolers also allows manufacturers to optimize storage and reduce waste by ensuring products are kept at optimal temperatures.

On the other hand, some food products are highly sensitive to temperature changes. For example, certain pharmaceutical ingredients, chocolates, and delicate desserts can lose their quality or effectiveness if exposed to improper temperatures.

Food also goes through a complex distribution network, and maintaining the cold chain—ensuring proper temperature control from production to consumption—is vital for preserving food safety and quality.

Cross-contamination is a concern in food manufacturing too. Proper temperature monitoring can help prevent allergen contamination by ensuring that allergen-containing foods are stored separately and at safe temperatures.

Additionally, monitoring systems often generate electronic records of temperature data, providing a documented history of cooler conditions. These records can be essential for audits, investigations, and quality assurance.

In the event of equipment failures or power outages, real-time monitoring with Sonicu can also alert staff to take immediate action, minimizing the risk of spoilage and ensuring timely corrective measures are taken.

Lastly, monitoring cooler conditions can help manufacturers identify trends and patterns in temperature fluctuations, allowing them to optimize their cooling processes and reduce energy consumption.

Continuous monitoring of food manufacturing coolers is vital for maintaining food safety, quality, regulatory compliance, and operational efficiency. It helps prevent spoilage, minimize waste, and ensures that consumers receive safe and high-quality food products.

Sonicu | Remote Wireless Monitoring for Food Safety

Sonicu listens to customers and clients who rely on our state-of-the-art technology designed with safety, efficiency and compliance.

We hear their need for cloud-based wireless food safety temperature monitoring systems. We help healthcare, research, and food service teams eliminate manual logging, improve compliance readiness, and protect all your temperature-sensitive assets.

Sonicu’s cooler monitoring technology ensures asset protection by detecting and responding to any temperature excursion that can threaten virtually anything perishable: food, especially meat, poultry, fish, eggs, dairy products, fruits and vegetables, medications, and natural materials.

You can learn more about how our software helps compliance professionals in these case studies:

Problem: Data loggers that were not on the cloud and cloud-based solution that only connected via wi-fi

Solution: Cloud-based solution with connectivity in wi-fi AND cellular for maximum flexibility and compliance readiness

Problem: An aging walk-in cooler with a faulty electrical system caused system failure and a loss of $5,000 in food

Solution: Simple and affordable temperature monitoring solution that protects costly food and automates compliance.

Components of Food Manufacturing Cooler Monitoring Systems

There are several advanced technologies available in the market for monitoring food manufacturing coolers and ensuring optimal storage conditions. These technologies utilize various sensors, data collection methods, and software to provide real-time monitoring, data analysis, and alerts.

- Wireless temperature monitoring systems use wireless sensors placed inside coolers to continuously monitor temperature and humidity levels.

- The data is transmitted wirelessly to a central monitoring station or cloud-based platform, where users can access real-time information and receive alerts if conditions deviate from preset parameters.

- The data is transmitted wirelessly to a central monitoring station or cloud-based platform, where users can access real-time information and receive alerts if conditions deviate from preset parameters.

- IoT (Internet of Things) enabled sensors and devices can provide comprehensive monitoring of various parameters, such as temperature, humidity, air pressure, and door status.

- These devices are connected to the internet, allowing remote monitoring through web-based dashboards or mobile apps.

- These devices are connected to the internet, allowing remote monitoring through web-based dashboards or mobile apps.

- RFID (Radio Frequency Identification) tags or sensors can be placed on individual food products or packages to track their location and temperature throughout the supply chain.

- This technology helps ensure that products are stored and transported under proper conditions.

- This technology helps ensure that products are stored and transported under proper conditions.

- Data loggers are portable devices that record temperature and humidity data over a specified period.

- They can be placed inside coolers to collect data, which can later be retrieved and analyzed.

- Some advanced data loggers offer real-time monitoring capabilities and wireless data transfer.

- They can be placed inside coolers to collect data, which can later be retrieved and analyzed.

- Automated Alert Systems send out alerts via email, SMS, or app notifications when temperature or other conditions exceed predetermined thresholds.

- Some solutions offer analytics and reporting capabilities, allowing manufacturers to analyze historical data, identify trends, and optimize their cooling processes for efficiency and quality.

- Certain technologies allow users to remotely adjust cooler settings based on real-time data, ensuring that conditions remain within optimal ranges.

It's important to note that the choice of monitoring technology depends on factors such as the specific needs of the food manufacturing process, the type of products being stored, regulatory requirements, budget constraints, and the level of automation desired.

You can learn more about how our software helps compliance professionals in these case studies:

Problem: Pharmacy Suffered Too Much Humidity In New Wing, impacting Compounding Pharmacy

Solution: Affordable Humidity Monitoring that Delivered Powerful data to prompt contractors to fix improperly sized air handler

Problem: The dining department struck with regulatory violations

Solution: Enterprise-wide monitoring that automates regulatory compliance across all departments

Problem: Release of lead particles in battery projects

Solution: Mobile, affordable air pressure monitoring solution

Cloud-Based Food Manufacturing Cooler Monitoring Technology

Cloud-based solutions store temperature and environmental data in remote servers. Users can access this data from anywhere with an internet connection, allowing for real-time monitoring, historical analysis, and remote alert notifications.

Cloud-based solutions for monitoring food manufacturing coolers offer several advantages over traditional methods, enhancing convenience, accessibility, and efficiency.

First of all, cloud-based platforms provide real-time access to temperature and environmental data from any location with an internet connection. This allows manufacturers and stakeholders to monitor conditions remotely, making it easier to manage multiple locations or facilities.

Cloud-based systems can also easily scale to accommodate the monitoring needs of small to large operations. As your business grows or you expand your operations, you can add more sensors and devices without significant infrastructure changes.

Cloud-based solutions often eliminate the need for extensive hardware and IT infrastructure investments. Instead of setting up and maintaining servers, you can rely on the service provider's infrastructure, reducing capital requirements and operational expenses.

Also, data from sensors is automatically collected and uploaded to the cloud, minimizing the need for manual data entry and reducing the potential for human errors.

Cloud-based systems also offer real-time monitoring and generate instant alerts via email, SMS, or mobile apps. This enables rapid response to any deviations from preset parameters, helping to prevent food spoilage and quality issues.

Additionally, cloud platforms store historical data, allowing manufacturers to analyze trends over time. This data can be used to identify patterns, optimize processes, and make informed decisions for process improvement.

Many cloud-based solutions also provide reporting and compliance features, making it easier to generate audit-ready reports for regulatory agencies or internal quality control purposes.

Cloud services typically have high levels of reliability and uptime. This minimizes the risk of data loss due to system failures, ensuring continuous monitoring and data collection.

Cloud platforms also enable easy sharing of data and reports with various stakeholders, including quality control teams, management, regulatory agencies, and suppliers.

Finally, cloud-based systems can contribute to reduced environmental impact by eliminating the need for physical servers and data storage on-site.

In addition to aiding food manufacturing cooler monitoring technology, Sonicu plays a vital role for organizations in other industries such as Ohio University and others including:

- Healthcare: Nurses respond to our alerts to keep your medicine safe

- Life Science/Lab: Lab directors rely on our alerts to protect priceless research

- Universities: Research and science department heads

- Food Service: Food distributors rely on our tech to protect your dinner

How to select the best food manufacturing cooler monitoring technology providers

When selecting the best food manufacturing cooler monitoring technology provider, there are several key factors to consider to ensure that you choose a solution that meets your specific needs and delivers reliable performance.

To begin with, the monitoring system should provide accurate and reliable data to ensure the safety and quality of your products. Look for providers with a track record of delivering precise measurements and consistent performance.

High-quality sensors are also crucial for accurate data collection. Ensure that the provider uses reputable and well-calibrated sensors that are suitable for the specific temperature and environmental conditions of your cooler.

The technology should be user-friendly and intuitive too. The user interface, dashboard, and mobile app should be easy to navigate and provide clear insights into cooler conditions.

The system should also offer real-time monitoring capabilities and customizable alert notifications that promptly inform you of any temperature deviations or other issues.

If opting for a cloud-based solution, assess the platform's features, ease of access, data visualization, and reporting capabilities. Make sure it meets your reporting and compliance needs.

Sonicu offers a comprehensive solution for temperature monitoring by utilizing wireless sensors that can be strategically placed in diverse locations and environments. These sensors efficiently collect data, which is then transmitted to our cloud-based platform, SoniCloud.

From SoniCloud, users can conveniently access and monitor the data remotely through their smart device.

Ensure you choose a solution that can grow with your business. Verify that it's easy to add additional sensors, devices, or monitoring points as your operations expand.

Data security is also crucial, especially when using cloud-based solutions. The provider should employ robust security measures, such as encryption, authentication, and regular security updates to safeguard your sensitive data.

A responsive and knowledgeable customer support team is essential too. Make sure the provider offers timely technical support, troubleshooting assistance, and training resources.

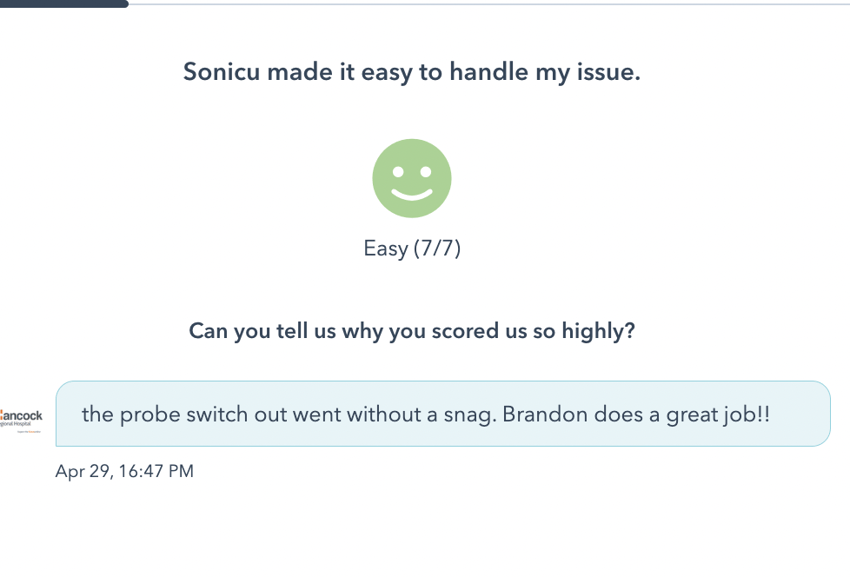

Our customers at Sonicu stay with us thanks to our American-based customer support, which is never more than a phone call away. While our technology is intuitive and powerful, we know it’s only as strong as the people who stand behind it.

The technology should also allow you to customize parameters, alerts, and reports to align with your specific requirements and regulatory compliance needs.

Additionally, choose a provider with a reliable track record and high system uptime to ensure continuous monitoring without interruptions.

Evaluate the total cost of ownership, including upfront costs, subscription fees (if applicable), and any additional expenses. Consider the value the solution provides in terms of food safety, reduced waste, and operational efficiency.

Look for customer reviews, testimonials, and case studies to gauge the experiences of other users with the provider's technology.

Ensure that the monitoring system is also compatible with the types of coolers or storage units you use in your food manufacturing process.

If your industry is subject to specific regulations (e.g., FDA, HACCP), also verify that the technology meets the necessary compliance standards.

Lastly, choose a provider that demonstrates a commitment to innovation and staying current with technology trends. This ensures that your monitoring solution will remain relevant and effective as new advancements emerge.

By carefully evaluating these factors and conducting thorough research, you can identify a food manufacturing cooler monitoring technology provider that aligns with your business goals and helps you maintain the highest standards of food safety and quality.

Food Manufacturing Cooler Monitoring Mobile App Technology

Food manufacturing cooler monitoring mobile app technologies provide a convenient and accessible way for users to monitor and manage cooler conditions directly from their smartphones or tablets. These apps offer real-time insights, alerts, and remote control capabilities, enhancing the efficiency of food safety and quality management.

First of all, mobile apps allow users to view real-time temperature, humidity, and other environmental conditions within their food manufacturing coolers. This helps identify potential issues promptly and take immediate action.

Mobile apps can also send push notifications, SMS messages, or emails to users when cooler conditions deviate from preset parameters. Alerts enable quick response and intervention to prevent spoilage and quality issues.

Sonicu has designed alerts and alarms around one simple goal: ensuring you and your team receive the right message at the right time to protect your assets, staff and clients. When coupled with our dashboard, the Sonicu mobile app serves as your mobile connection to all your sensitive assets and environments.

A well-designed and intuitive user interface is crucial for ease of use. The app should be straightforward to navigate, with clear icons, labels, and intuitive controls.

Look for apps that allow users to customize alert thresholds, monitoring intervals, and other settings to match specific cooler requirements and operational needs.

Some apps also support multi-device access, allowing multiple users to monitor cooler conditions simultaneously. This is particularly useful for teams responsible for food safety and quality control.

Also, ensure that the app is compatible with various mobile devices and operating systems, such as iOS and Android, so that users can access it from their preferred devices.

In environments with intermittent internet connectivity, having an offline mode can be valuable as well. This feature enables the app to continue collecting data even when a stable connection is not available, with the data syncing once a connection is restored.

Some mobile apps also allow users to generate reports and documentation directly from their devices. This can simplify compliance with regulatory requirements and facilitate quality audits.

Choose apps from reputable providers that offer regular updates, bug fixes, and responsive customer support to ensure a smooth user experience.

Lastly, look for apps that provide user guides, tutorials, and resources to help users make the most of the app's features and capabilities.

Food manufacturing cooler monitoring mobile app technologies offer flexibility and convenience, enabling users to stay connected to their cooler conditions and make informed decisions on the go. When evaluating app options, prioritize user-friendliness, real-time monitoring, and the ability to customize settings to suit your specific needs.

Seize the Opportunity: Why Investing in Sonicu is a No-Brainer

As we journey through the intricacies of food manufacturing, one thing becomes abundantly clear: the stakes couldn't be higher. From ensuring food safety to preserving quality, the delicate dance of temperature and environment is a symphony that must be orchestrated flawlessly. But fear not, for in this era of innovation, a powerful ally emerges to champion your cause—food manufacturing cooler monitoring technology. At Sonicu, we prioritize customer satisfaction and swiftly address any support request that comes our way. We are only one call or click away!

Imagine a world where you can oversee your coolers' conditions from the palm of your hand. A world where real-time insights and alerts are at your fingertips, guiding you to prevent potential disasters and unlocking new levels of efficiency. This world is not a distant dream—it's a reality waiting to be embraced.

In the heart of your food production, these technological marvels silently stand guard, tirelessly collecting data, and revealing the secrets of your coolers. Cloud-based solutions and cutting-edge mobile apps empower you to transcend physical boundaries, ensuring that your products' quality remains uncompromised, no matter where you are.

What does this mean for you? It means reduced waste, safeguarded profits, and a reputation that shines as brightly as the North Star. It's the assurance that every batch of goods leaving your facility is a testament to your commitment to excellence. It's the power to adapt, scale, and grow without fear, knowing that your monitoring technology can evolve right alongside you.

But don't take our word for it—take the stories of thriving manufacturers who have harnessed this technology to their advantage. From seamless regulatory compliance to unprecedented insights that drive smarter decisions, their success stories are a testament to the transformative impact of food manufacturing cooler monitoring technology.

So, as you embark on your quest for quality and success, consider this your call to arms. Embrace the power of innovation and elevate your operations to heights unimagined. Let your coolers be the guardians of perfection, guided by the marvels of modern technology. The journey may be bold, but the rewards are grand. Step forth and invest in the future of food manufacturing cooler monitoring technology, and let your legacy be one of excellence, precision, and prosperity.

Are you ready to join the ranks of visionary manufacturers who are shaping the future of the industry with Sonicu? The choice is yours, and the possibilities are limitless.

Welcome to the future. Welcome to success.

American-based Customer Support: Robust & Reliable High Touch Service

Software and technology is only as good as the people who stand behind it.

At Sonicu, that means our team of American-based customer success managers who are never more than a phone call away to help field and fix any service issues.

Our probes and sensors are placed in demanding frozen environments and our software literally sends billions bits of data monthly, meaning there’s always the potential for a hiccup on either the hardware or software.

We are committed to fielding every customer service request promptly and addressing our customer’s concerns promptly and professionally.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

The Sonicu Difference

Advanced Alarming

Cloud-based software capabilities with predictive algorithms for tailored alarming to reduce alarm fatigue and spot trends.

SMART Digital Sensors

SMART sensors with proprietary DataSync capture. Preserve and secure data in the event of transmission interruptions.

SMART Reporting

Automated logging and reporting unrivaled in the industry for effortless regulatory compliance.

Battery Backup

Industry leading battery life on all sensors. In the event of a power outage Sonicu's wireless sensors continue to keep you notified.

The Safest Network

Virtual Private Network on Verizon cellular platform that eliminates security concerns when transmitting data to the cloud.

Flexible Transmission

Replace server-based systems and eliminate IT concerns with a variety of transmission signals including: Cellular, Radio Frequency, WiFi, and Ethernet.

Recalibration is Easy

All-digital temperature probes for easy calibration renewal with Sonicu's SNAP calibration program.

Ensuring Consistency

Service quality and connectivity reports provide detailed analysis of system operations.

How IU Health

consolidated all of its pharmacy monitoring needs

into one cloud-based platform serving dozen of locations.