Food Safety Monitoring System

If you are looking for a food safety monitoring system that helps you and your team eliminate manual logging, improve compliance readiness, and protect all your temperature-sensitive assets, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts via text, email, push notifications and phone calls to protect your precious assets

- Compliance: Automated compliance reports

- Efficiency: Reduced Manual Logging and time spent on reports

- Robust Redundancy: Battery Backup and DataSync for reliable data continuity

And what makes us different?

- Lifetime Warranty: Ongoing warranty included with monitoring subscription

- Unlimited Users: Scale across your entire organization

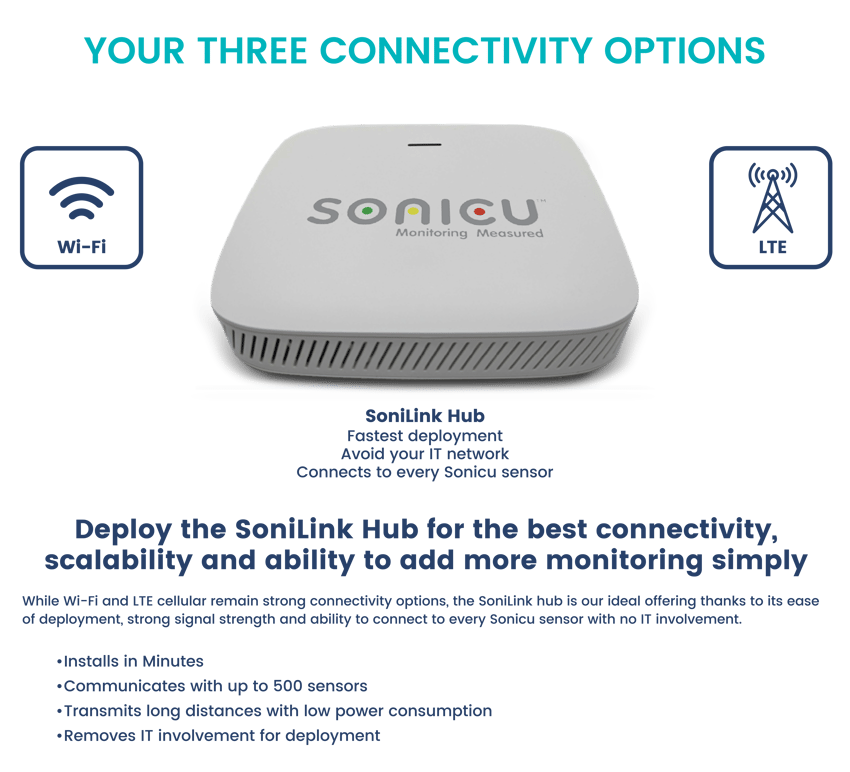

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

- Mobile App: 500 Freezers in your pocket

- Facility monitoring: Simple to add water leak, door open, occupancy, and even IAQ monitoring

Engineered in Indiana with U.S.-based support.

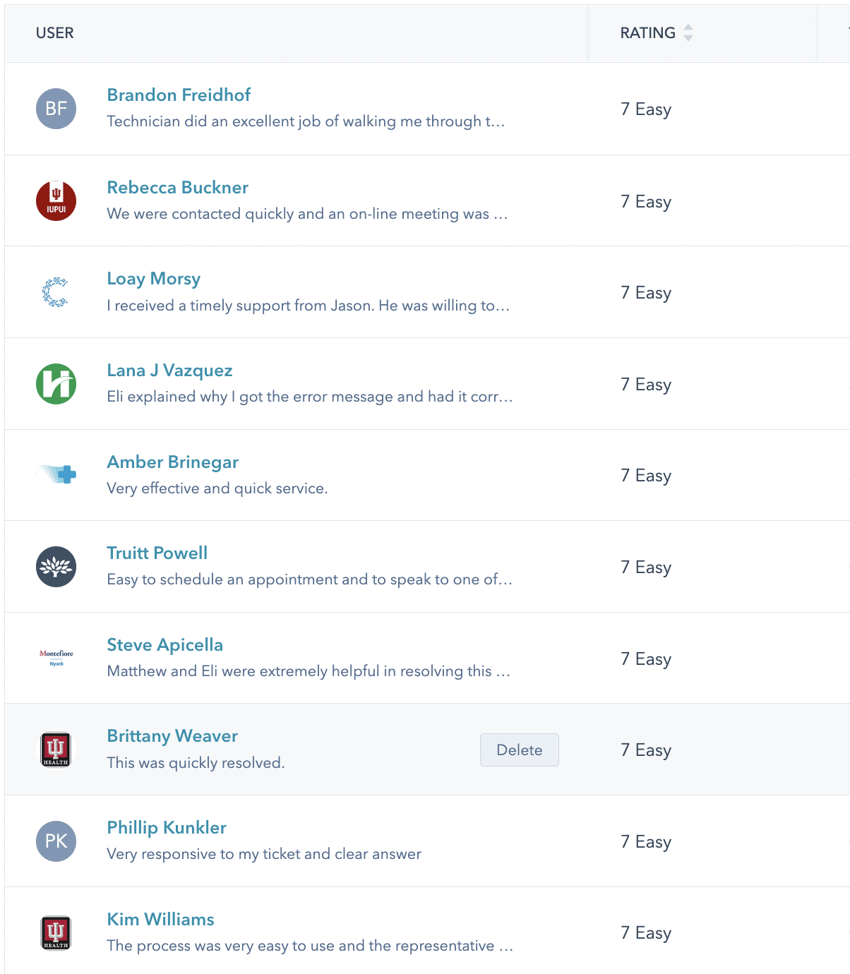

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

These respected healthcare and research brands turn to Sonicu for four primary reasons:

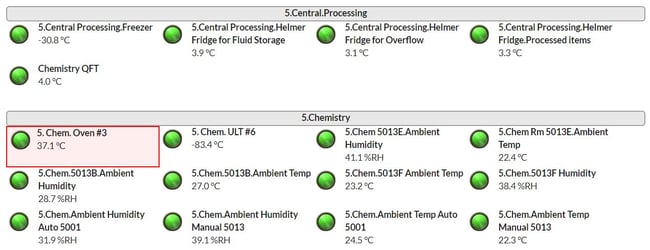

- Real-Time Monitoring: the sensors collect temperature, humidity, air pressure data and more, and transmit it wirelessly to SoniCloud - our cloud-based platform.

- Operational Efficiency: Virtually eliminate the need for tedious and costly manual logging

- Compliance Automation: Respond to any regulatory audit or inspection in a few clicks with our reports section

- Asset Protection: Detect and respond to any threshold that can threaten anything perishable: food, drugs, vaccines, research, etc.

.png?width=2000&height=312&name=Food%20Trust%20Bar%20Logos%20(2).png)

Mastering Food Safety: How The Food Safety Monitoring System is Setting New Industry Standards

A food safety monitoring system takes an integrated approach used to ensure that food products are consistently produced and controlled according to quality and compliance standards. It's designed to minimize risks and hazards in food production, processing, handling, and distribution. This system includes various methods, procedures, and tools to track, record, and analyze factors that affect food safety, such as temperature control, contamination prevention, hygiene practices, and the use of safe raw materials.

The utilization of food safety monitoring systems is deemed essential in several niches of the food industry.

In agriculture and farming, a food safety monitoring system can ensure crops and livestock are free from contaminants and grown or raised under safe conditions.

In food processing and manufacturing, these solutions help monitor the safety and quality of food during processing, packaging, and storage.

They also ensure that during transportation and warehousing, food products are stored and handled in ways that prevent spoilage and contamination.

Restaurants, supermarkets, and other food service providers use the food safety monitoring system to ensure food is stored, handled, and prepared safely.

The impact of a food safety monitoring system on the day-to-day operations of companies in these sectors is critical.

To begin with, a food safety monitoring system helps ensure adherence to local and international food safety standards and regulations.

It also plays an essential part in minimizing the risk of foodborne illnesses and contamination, thus protecting consumer health.

Maintaining high standards of food safety enhances a company's reputation and consumer trust.

A food safety monitoring system fast tracks operational efficiency by streamlining the process, reducing waste, and leading to cost savings in the long run.

These solutions also facilitate data-driven decision-making by providing valuable data that can be leveraged for making informed decisions and continuous improvement in food safety practices.

Sonicu has around 700 customers in all 50 states, as well as in Canada and the Caribbean and serves the healthcare, life sciences, pharmaceutical, and food service industries. Customers trust Sonicu to monitor cold storage temperature, ambient room condition temperature and humidity, air pressure differential and noise.

If you care about receiving safe medicines from the pharmacist, safe vaccines from your doctor and safe food from your grocery, you care about temperature and conditions monitoring.

Lastly, compliance with safety standards is often a prerequisite for entering certain markets or working with specific retailers.

A robust food safety monitoring system is vital for maintaining the highest standards of food quality and safety, which in turn supports the smooth and efficient operation of food-related businesses.

You can learn more about how our software helps compliance professionals in these case studies:

Problem: Data loggers that were not on the cloud and cloud-based solution that only connected via wi-fi

Solution: Cloud-based solution with connectivity in wi-fi AND cellular for maximum flexibility and compliance readiness

Problem: An aging walk-in cooler with a faulty electrical system caused system failure and a loss of $5,000 in food

Solution: Simple and affordable temperature monitoring solution that protects costly food and automates compliance.

The components of food safety monitoring systems

The components of a typical food safety monitoring system vary depending on the specific needs and scale of the operation, but generally, they include a combination of hardware, software, and procedural elements. These components leverage various technologies to perform their functions efficiently.

- Sensors and monitoring devices

- These include temperature sensors, humidity sensors, and pH sensors used in food storage and processing areas.

- IoT (Internet of Things) technology is often used, allowing real-time monitoring and data collection.

- Data analytics and management software

- Software solutions that collect, store, and analyze data from various sources within the food supply chain.

- This can include batch tracking, shelf-life monitoring,trend analysis, and freshness expectancy.

- Traceability systems

- Technologies such as RFID (Radio-Frequency Identification) and barcoding are used to track food products throughout the supply chain.

- This ensures that, in the event of a contamination issue, the source of contamination can be quickly identified, and the impact minimized.

- Quality management systems (QMS)

- Laboratory information management systems (LIMS)

- Used in testing labs for managing samples, testing workflows, and storing test results to ensure that food products meet safety and quality standards.

- Mobile applications

- Used for on-site data collection, reporting, and communication. Inspectors or employees can input data directly into the system from the field or production floor.

- Cloud computing

- Facilitates data storage and access, allowing various stakeholders within the supply chain to access real-time information from anywhere.

- Training and compliance tools

- E-learning platforms and digital documentation help in training staff on food safety protocols and compliance requirements.

By integrating these technologies, a food safety monitoring system can provide comprehensive oversight and control over the entire food supply chain, enhancing the ability to prevent, detect, and respond to food safety issues. This integrated approach also contributes to greater operational efficiency, cost savings, and improved compliance with regulatory standards.

Companies such as Tyner Pond Farm have trusted Sonicu to provide them with peace of mind when it comes to food safety monitoring. Other benefits they receive by choosing Sonicu include:

- Asset Protection: Get alerts when a freezer is malfunctioning to protect assets such as medicines, vaccines, blood, research, sperm/eggs

- Compliance Automation: Creates simple reports to satisfy local/state/federal regulations

- Operational Efficiency: Spend less time capturing data manually: Both temps/conditions and reporting

What are the pain points that a food safety monitoring system can resolve effectively?

A food safety monitoring system is designed to address several critical and often challenging issues in the food industry.

- Pain point: Contamination, whether microbial, chemical, or physical, poses a significant risk.

- Solution: Food safety monitoring systems help in the early detection and control of contaminants, thereby preventing potential foodborne illnesses.

- Pain point: Maintaining the right temperature during storage and transportation is crucial for many food products.

- Solution: Automated temperature monitoring and alerts help in the prevention of spoilage and ensuring product quality.

- Pain point: The food industry is subject to numerous regulations.

- Solution: A food safety monitoring system can streamline the process of compliance by ensuring that all necessary protocols are followed and documented.

- Pain point: In case of a food safety incident, it is vital to trace back to the source quickly.

- Solution: A food safety monitoring system, especially one using technologies such as RFID or blockchain, enhances traceability, enabling quick action in recall situations.

- Pain point: Manual quality checks are prone to errors and inconsistencies.

- Solution: Automated systems provide consistent and objective monitoring, ensuring product quality and uniformity.

- Pain point: Supply chain inefficiencies

- Solution: A food safety monitoring system can optimize the supply chain by providing real-time data on inventory, production, and distribution, helping to reduce waste and inefficiencies.

- Pain point: Handling large volumes of data and reporting for compliance can be overwhelming.

- Solution: These systems simplify data management, analysis, and reporting processes.

- Pain point: Issues with food safety can significantly damage a brand.

- Solution: Proactive monitoring and swift response to potential issues help in maintaining consumer trust and brand reputation.

- Pain point: Keeping staff updated with the latest food safety practices can be challenging.

- Solution: Some systems offer training modules and updates to ensure that all employees are well-informed.

- Pain point: Food safety regulations can change frequently.

- Solution: Monitoring systems can be updated to comply with the latest standards, ensuring that businesses remain compliant.

By tackling these pain points, food safety monitoring systems not only enhance the safety and quality of food products but also contribute to operational efficiency, risk management, and overall sustainability in the food industry.

Piazza Produce has entrusted Sonicu and received these top features:

- American-based customer service and tech support

- Redundancy of power/connectivity to protect data integrity

- SNAP calibration service for NIST compliance

- Hardware assembled in the United States

- Built on AWS Cloud for simplicity, speed, reliability, and scalability

You can learn more about how our software helps compliance professionals in these case studies:

Problem: Pharmacy Suffered Too Much Humidity In New Wing, impacting Compounding Pharmacy

Solution: Affordable Humidity Monitoring that Delivered Powerful data to prompt contractors to fix improperly sized air handler

Problem: The dining department struck with regulatory violations

Solution: Enterprise-wide monitoring that automates regulatory compliance across all departments

Problem: Release of lead particles in battery projects

Solution: Mobile, affordable air pressure monitoring solution

What are the key benefits of implementing a food safety monitoring system?

- By continuously monitoring and controlling potential hazards, a food safety monitoring system significantly reduces the risk of foodborne illnesses and contamination, ensuring safer food products for consumers.

- They help businesses stay compliant with local and international food safety standards, such as HACCP (Hazard Analysis and Critical Control Points), FDA regulations, and ISO standards. This compliance is crucial for legal operations and market access.

- Consistent monitoring of the production process leads to higher-quality products. This includes maintaining proper storage conditions, handling practices, and production processes.

- In the event of a contamination or recall, a food safety monitoring system allows for quick and accurate traceability of products throughout the supply chain. This efficiency is critical for addressing safety issues promptly and minimizing potential harm.

- By preventing spoilage and improving operational efficiencies, food safety monitoring systems can lead to significant cost savings and reduced food waste.

- Demonstrating a commitment to food safety enhances consumer confidence and loyalty, which is vital for brand reputation and long-term success.

- The collection and analysis of data provide valuable insights for decision-making. This can include improving production processes, supply chain management, and developing strategies to address market demands.

- Automation of monitoring tasks reduces the labor and time required for manual checks, leading to increased operational efficiency.

- Proactive monitoring and early detection of potential issues help in mitigating risks, avoiding costly recalls, and legal issues.

- Compliance with international food safety standards can open up new markets and expand business opportunities globally.

- By reducing waste and optimizing resource usage, these systems can contribute to more sustainable and environmentally friendly operations.

Securing Your Future with Sonicu: The Final Word in Advanced Food Safety Solutions

In conclusion, the importance of a robust food safety monitoring system in today's ever-evolving food industry cannot be overstated. With the growing demands for higher safety standards, regulatory compliance, and consumer expectations for quality, the role of efficient and reliable monitoring systems such as those offered by Sonicu becomes increasingly critical.

Sonicu's state-of-the-art food safety monitoring system is more than just a compliance tool; it's a gateway to operational excellence, enhanced food safety, and business growth. By leveraging cutting-edge technology, Sonicu helps businesses stay ahead of potential hazards, ensures products are of the highest quality, and protects the brand's reputation, all while fostering consumer trust.

The true value of Sonicu's system lies in its ability to transform challenges into opportunities. From reducing waste and cutting costs to unlocking new market potentials and driving innovation, Sonicu is not just a solution; it's a strategic partner in your journey toward excellence in food safety.

As we navigate this dynamic and competitive landscape, the question is no longer about whether to implement a food safety monitoring system, but rather, how quickly can you integrate a solution as comprehensive and reliable as Sonicu. Remember, in the realm of food safety, the right decision today can define your success tomorrow.

Don't wait for a food safety crisis to be the wake-up call. Be proactive. Embrace the future of food safety with Sonicu. Contact us today to learn more about how our food safety monitoring system can revolutionize your operations and safeguard your future. Your journey towards impeccable food safety standards begins with Sonicu – let's take this step together.

Embrace Safety, Embrace Success with Sonicu

American-based Customer Support: Robust & Reliable High Touch Service

Software and technology is only as good as the people who stand behind it.

At Sonicu, that means our team of American-based customer success managers who are never more than a phone call away to help field and fix any service issues.

Our probes and sensors are placed in demanding frozen environments and our software literally sends billions bits of data monthly, meaning there’s always the potential for a hiccup on either the hardware or software.

We are committed to fielding every customer service request promptly and addressing our customer’s concerns promptly and professionally.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

The Sonicu Difference

Advanced Alarming

Cloud-based software capabilities with predictive algorithms for tailored alarming to reduce alarm fatigue and spot trends.

SMART Digital Sensors

SMART sensors with proprietary DataSync capture. Preserve and secure data in the event of transmission interruptions.

SMART Reporting

Automated logging and reporting unrivaled in the industry for effortless regulatory compliance.

Battery Backup

Industry leading battery life on all sensors. In the event of a power outage Sonicu's wireless sensors continue to keep you notified.

The Safest Network

Virtual Private Network on Verizon cellular platform that eliminates security concerns when transmitting data to the cloud.

Flexible Transmission

Replace server-based systems and eliminate IT concerns with a variety of transmission signals including: Cellular, Radio Frequency, WiFi, and Ethernet.

Recalibration is Easy

All-digital temperature probes for easy calibration renewal with Sonicu's SNAP calibration program.

Ensuring Consistency

Service quality and connectivity reports provide detailed analysis of system operations.

We realized there had to be a better way and went in search of technology that could give us that level of monitoring that would keep our patients safe. Sonicu made it easy and we grew across the entire hospital.