Food Traceability and Safety Monitoring

If you’re looking for a food traceability solution that eliminates manual logging, improves compliance readiness and protects all your inventory regardless of temperature, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts via text, email, push notifications and phone calls to protect your precious assets

- Compliance: Automated compliance reports

- Efficiency: Reduced Manual Logging and time spent on reports

- Robust Redundancy: Battery Backup and DataSync for reliable data continuity

And what makes us different?

- Lifetime Warranty: Ongoing warranty included with monitoring subscription

- Unlimited Users: Scale across your entire organization

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

- Mobile App: 500 Freezers in your pocket

- Facility monitoring: Simple to add water leak, door open, occupancy, and even IAQ monitoring

Engineered in Indiana with U.S.-based support.

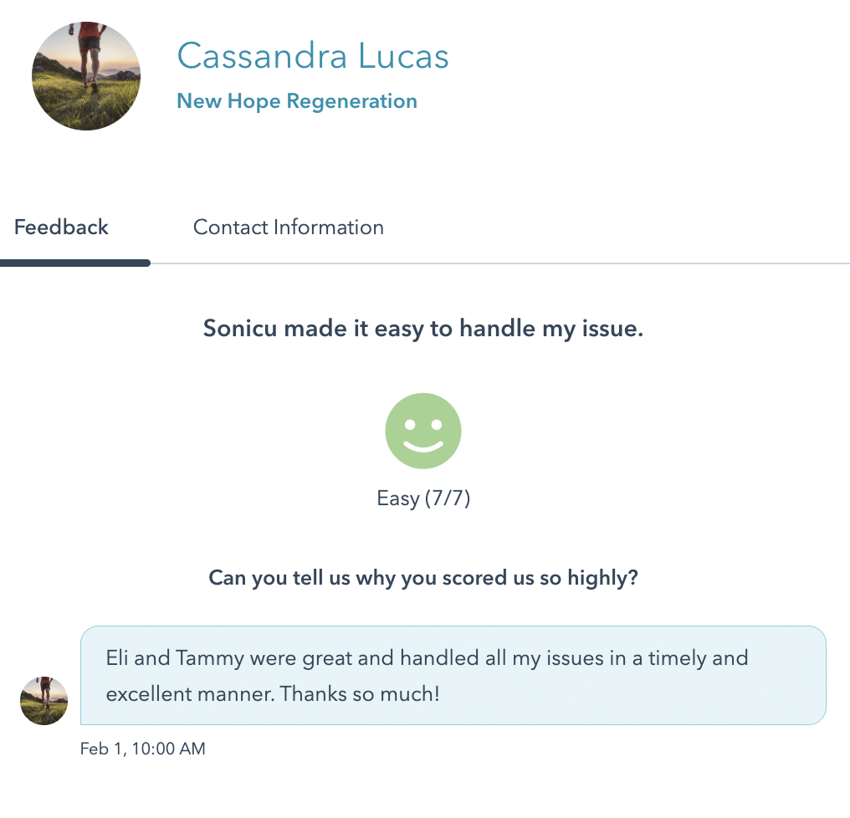

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

.png?width=2000&height=312&name=Food%20Trust%20Bar%20Logos%20(2).png)

Food Traceability and Safety: Growing Importance in the Food Industry

The Increasing Importance of Temperature Monitoring in Meeting Food Safety Regulations

From family dinners to large-scale catered meals, the food we eat — and how safe it is before preparing and consuming it — plays a vital role in our everyday lives.

Our health and well-being and overall safety create high demand within the agriculture, food service, distribution, warehouse and compliance industries for transparency.

Any changes in these industries with regulations and oversight, especially on the federal level, shine the spotlight on the importance of food traceability and smarter food safety.

The following article highlights changes that impact nearly every organization involved in the production, transportation and storage of food.

And includes special attention on the role temperature monitoring plays in meeting those regulations.

FDA Food Traceability List

Food traceability is designed to deliver product and supply chain visibility and industry compliance to help agriculture and foodservice providers prevent foodborne illnesses.

The Food and Drug Administration (FDA) oversees and advises on food safety by identifying items requiring specific protection in its Food Traceability List (FTL).

This list covers everything from dairy and meats to fruits and vegetables.

More specifically, Section 204 of the FDA Food Safety Modernization Act (FSMA) requires the FDA to “designate foods for which additional recordkeeping requirements are appropriate and necessary to protect public health, and to establish those recordkeeping requirements.”

Such public health transparency is outlined in the Requirements for Additional Traceability Records for Certain Foods (Food Traceability) proposed rule, and is “intended to make it easier to rapidly and effectively track the movement of a food to prevent or mitigate a foodborne illness outbreak.”

According to the FDA, the FTL identifies foods “for which the additional traceability records described in the proposed rule would be required.

As noted in the proposed rule, the additional recordkeeping requirements would apply not only to foods specifically listed on the FTL, but also to foods that contain those same items on the list as ingredients.”

In January 2021, the FDA updated descriptions of particular foods on the list for clarification purposes.

The designations affected the Risk-Ranking Model for Food Tracing in items such as cheeses, especially regarding their designation as “hard,” specifically referring to the percentage of moisture (hard cheeses such as cheddar, Romano and parmesan are defined as having less than 39s% moisture) and “fresh.”

The FDA reports that the word “fresh” was not included in previous versions of the food traceability chart, especially for clarification of:

- cucumbers

- leafy greens

- melons

- peppers

- sprouts

- tomatoes

- tropical tree fruits.

The update also removed collards from the description of leafy greens, as they are listed as “rarely consumed raw” in the produce safety regulation.

For more information on the Risk-Ranking Model for Food Tracing, see the FDA’:

“Full List of References in the Risk-Ranking Model for Food Tracing.”

A New Era of Smarter Food Safety

Along with updates to the Food Traceability List, the FDA also recently modernized food safety and traceability protocols with its:

New Era of Smarter Food Safety and

New Era of Smarter Food Safety Blueprint

The FDA says its “ultimate goal is to bend the curve of foodborne illness in this country by reducing the number of illnesses.”

Frank Yiannas, FDA Deputy Commissioner for Food Policy and Response, stressed that collaboration is key to a safer future for our food and its traceability function.

“It’s more important today than ever before in our history to work together to create a more digital, traceable and safer food system,” Yiannas said in a public statement.

The FDA launched its New Era of Smarter Food Safety Blueprint in July 2020 to establish “achievable goals for enhanced traceability, improve predictive analytics, respond more rapidly to outbreaks, address new business models, reduce contamination of food, and foster the development of stronger food safety cultures.”

The FDA has made the following items central to its strategy:

tech-enabled traceability

smarter tools and approaches for prevention and outbreak response

new business models and retail modernization

and food safety culture

These priorities align with Sonicu’s automated remote monitoring kit solution that offers food service providers with superior asset protection to ensure food safety and traceability of temperature and other environmental conditions.

Food Traceability List Updates

These updates, and the importance of food traceability, are integral to Sonicu’s delivery of full-service monitoring solutions such as monitoring of cold and frozen temperature storage and even ambient conditions.

Sonicu helps clients such as Piazza Produce and Specialty Foodsprotect their products and profit by monitoring desired temperatures to foster safe and sanitary conditions in real-time.

Piazza’s high-quality products include fresh fruits, vegetables, herbs, proteins, and organic, prepared and natural foods — all common items that cannot be spoiled or contaminated prior to use for preparation of meals and catered events.

Since these products require proper storage in well monitored environments, Piazza benefits from the peace of mind that their freezers, refrigerators and walk-ins are functioning 24/7, monitored from a customizable dashboard to prevent spoilage and loss.

When you couple the real-time monitoring with Sonicu’s ability to deliver automated compliance reports for federal, state and local agencies, Piazza has invested in an affordable and simple solution that helps them operate smarter and safer.

As the FDA continues to update the Food Traceability List and integrate its Food Safety Blueprint, Sonicu ensures that Piazza meets regulatory safety requirements with digital monitoring and paper back-ups.

The benefits of the Sonicu temperature monitoring system for Piazza and other food service providers include

asset protection (including alerts when a freezer malfunctions)

compliance automation to produce simple reports meeting local/state/federal regulations and compliance

and operational efficiency for less manual data captures and temps/conditions reporting

Global Food Safety Initiative Standards

Sonicu’s temperature monitoring system supports stakeholders at Piazza Produce, a Safe Quality Foods Institute SQF Level II Certified Company, by helping them meet and exceed Global Food Safety Initiative (GFSI) standards.

The GFSI is an international action group from The Consumer Goods Forum launched in 2000 as a non-profit.

It is composed of 42 retailers and manufacturers collaborating as a food safety oversight community to drive positive change through action.

The initiative establishes and maintains standards for businesses and helps provide access to safe food worldwide.

Here in the U.S., Sonicu wireless temperature monitoring helps local food service providers and businesses such as Piazza Produce, and others, streamline their operations and make regulatory compliance reporting simple.

Wireless temperature monitoring helps keep consumers safe by preventing spoilage and better navigating compliance audits.

This is achieved through constant temperature monitoring for freezers, refrigerators, walk-in coolers, cold warehouses and transport.

Farming Food Chain Safety

Sonicu’s advanced software capabilities also provide farm-to-table food traceability and production safety for Tyner Pond Farms, a 500-acre beef, pork chicken and turkey farm located in Greenfield, Ind.

The farm is dedicated to natural, pasture-raised livestock and sustainable farming, as well as transparent food traceability and smarter food safety.

Thanks to 24/7 automated remote monitoring, any potential threats to consumer safety and wellness from freezer failure due to power outages, human error and erratic performance can be easily and continuously detected.

To establish remote monitoring access onsite at Tyner Pond, Sonicu performed an assessment based on a demanding need for data-driven process controls and alarm notifications for temperature excursions on its meat freezers.

The days of tirelessly checking on equipment based on a hunch or bad feeling would soon be replaced with the insurance of state-of-the-art technology.

This helps Tyner Pond fulfill its mission of “providing grass-fed beef, local pork, pasture -raised chicken and turkey unmatched in quality and nutrition by using regenerative farming practices.”

The Natural Resources Defense Council (NRDC) defines the regenerative farming philosophy as an approach to land management that considers all aspects of agriculture connected as a network of entities rather than a linear supply chain.

This network grows, enhances, exchanges, distributes and consumes goods and services using holistic principles to restore soil and ecosystem health by considering the future of the land, waters and climate.

This philosophy, says the NRDC, benefits the health of farmers, farmworkers, and downstream communities by reducing use of and exposure to harmful chemicals. That supports global food safety in the farming food chain.

“When we speak with farmers and ranchers focused on regenerative agriculture, they tell us that their notion of ‘success’ goes beyond yield and farm size,” said Lara Bryant, NRDC deputy director of water and agriculture, in the “Regenerative Agriculture 101” guide available online.

“It includes things like joy and happiness, the number of families they feed, watching how the land regenerates and flourishes, the money saved from not purchasing chemical inputs, the debt avoided by repurposing old equipment, and the relationships built with community members,” Bryant said.

Tyner Pond Farms made it a goal to start with tangible agrifood safety on a local level. That begins with improving soil health and building and strengthening the local community by providing drug-free humanely-raised animals to consumers.

Regenerative farmers such as Tyner Pond Farms make growing healthy food for their families and communities a priority.

This all ties back to the importance of food traceability and transparency, as well as smarter food safety for consumers.

Sonicu was quick to help in providing an affordable and intuitive solution by installing a temperature probe and transmitter assembly programmed to broadcast data and updates via Wi-Fi.

Technology in motion for an age-old agriculture philosophy that dates back centuries.

Sonicu’s alarms with predictive algorithms could now spot Tyner’s meat freezer trends, reduce alarm fatigue, and escalate if needed.

Employees now receive instant, automated notifications of freezer performance variances to protect inventory and save time, money and effort.

Web-based access is available to them by phone, tablet and PC, 24/7, on the user-friendly SoniCloud Monitoring Dashboard.

This modern, scalable platform easily allows for viewing and monitoring anytime with best-in-class security and reliability.

The system’s DataSync feature ensures data integrity, and cellular VPN eliminates security breach concerns.

All-digital temperature probes provide easy recalibration with Sonicu's SNAP calibration program. These features provide a level of security and compliance the farm had not experienced in its past.

A Culture of Food Safety

From agriculture to food service distributors, such on-demand quality control and regulatory compliance are ensured with Sonicu’s 24/7/365 monitoring and data storage solutions.

Services also include humidity monitoring for proper storage, air pressure monitoring for critical areas, and power and machine-to-machine monitoring to maintain efficiency and lean manufacturing processes.

Sonicu allows for full-service operational management with superior operational visibility from a single platform.

This helps the FDA fulfill its promise to “foster, support and strengthen food safety cultures on farms, in food facilities, and in homes.”

The FDA says it will not “make dramatic improvements in reducing the burden of foodborne disease without doing more to influence the beliefs, attitudes, and, most importantly, the behaviors of people and the actions of organizations.”

The Michigan State University Extension reports that the changing mindset within the food safety culture continues to evolve.

According to the MSU Extension, food safety culture starts with looking at produce, and how it is handled in the operation, as food.

“It is very easy when handling bulk volumes of fruits or vegetables to think of it as a commodity, like corn or soybeans. By thinking of the produce as food, a culture of food safety begins.”

The Extension reminds us that fresh produce interactions, from harvest to distribution, impacts quality and safety. Understanding and evaluating food flow in this context is the next step in developing a culture of food safety, says the Extension.

“Whether it is recognizing that the holding temperature of the cooler is important, or understanding that healthy workers harvest and pack safe food, these realizations will begin to inform management decisions that drive change on the farm.”

Sonicu wholeheartedly agrees.

We believe our commitment to improving and promoting food safety shows in the affordability and simplicity of the products and technology we implement.

Food Traceability and Safety: Growing Importance in the Food Industry

The Increasing Importance of Temperature Monitoring in Meeting Food Safety Regulations

From family dinners to large-scale catered meals, the food we eat — and how safe it is before preparing and consuming it — plays a vital role in our everyday lives.

Our health and well-being and overall safety create high demand within the agriculture, food service, distribution, warehouse and compliance industries for transparency.

Any changes in these industries with regulations and oversight, especially on the federal level, shine the spotlight on the importance of food traceability and smarter food safety.

The following article highlights changes that impact nearly every organization involved in the production, transportation and storage of food.

And includes special attention on the role temperature monitoring plays in meeting those regulations.

FDA Food Traceability List

Food traceability is designed to deliver product and supply chain visibility and industry compliance to help agriculture and foodservice providers prevent foodborne illnesses.

The Food and Drug Administration (FDA) oversees and advises on food safety by identifying items requiring specific protection in its Food Traceability List (FTL).

This list covers everything from dairy and meats to fruits and vegetables.

More specifically, Section 204 of the FDA Food Safety Modernization Act (FSMA) requires the FDA to “designate foods for which additional recordkeeping requirements are appropriate and necessary to protect public health, and to establish those recordkeeping requirements.”

Such public health transparency is outlined in the Requirements for Additional Traceability Records for Certain Foods (Food Traceability) proposed rule, and is “intended to make it easier to rapidly and effectively track the movement of a food to prevent or mitigate a foodborne illness outbreak.”

According to the FDA, the FTL identifies foods “for which the additional traceability records described in the proposed rule would be required.

As noted in the proposed rule, the additional recordkeeping requirements would apply not only to foods specifically listed on the FTL, but also to foods that contain those same items on the list as ingredients.”

In January 2021, the FDA updated descriptions of particular foods on the list for clarification purposes.

The designations affected the Risk-Ranking Model for Food Tracing in items such as cheeses, especially regarding their designation as “hard,” specifically referring to the percentage of moisture (hard cheeses such as cheddar, Romano and parmesan are defined as having less than 39s% moisture) and “fresh.”

The FDA reports that the word “fresh” was not included in previous versions of the food traceability chart, especially for clarification of:

cucumbers

leafy greens

melons

peppers

sprouts

tomatoes

tropical tree fruits.

The update also removed collards from the description of leafy greens, as they are listed as “rarely consumed raw” in the produce safety regulation.

For more information on the Risk-Ranking Model for Food Tracing, see the FDA’:

“Full List of References in the Risk-Ranking Model for Food Tracing.”

A New Era of Smarter Food Safety

Along with updates to the Food Traceability List, the FDA also recently modernized food safety and traceability protocols with its:

New Era of Smarter Food Safety and New Era of Smarter Food Safety Blueprint

The FDA says its “ultimate goal is to bend the curve of foodborne illness in this country by reducing the number of illnesses.”

Frank Yiannas, FDA Deputy Commissioner for Food Policy and Response, stressed that collaboration is key to a safer future for our food and its traceability function.

“It’s more important today than ever before in our history to work together to create a more digital, traceable and safer food system,” Yiannas said in a public statement.

The FDA launched its New Era of Smarter Food Safety Blueprint in July 2020 to establish “achievable goals for enhanced traceability, improve predictive analytics, respond more rapidly to outbreaks, address new business models, reduce contamination of food, and foster the development of stronger food safety cultures.”

The FDA has made the following items central to its strategy:

tech-enabled traceability

smarter tools and approaches for prevention and outbreak response

new business models and retail modernization

and food safety culture

These priorities align with Sonicu’s automated remote monitoring kit solution that offers food service providers with superior asset protection to ensure food safety and traceability of temperature and other environmental conditions.

Food Traceability List Updates

These updates, and the importance of food traceability, are integral to Sonicu’s delivery of full-service monitoring solutions such as monitoring of cold and frozen temperature storage and even ambient conditions.

Sonicu helps clients such as Piazza Produce and Specialty Foodsprotect their products and profit by monitoring desired temperatures to foster safe and sanitary conditions in real-time.

Piazza’s high-quality products include fresh fruits, vegetables, herbs, proteins, and organic, prepared and natural foods — all common items that cannot be spoiled or contaminated prior to use for preparation of meals and catered events.

Since these products require proper storage in well monitored environments, Piazza benefits from the peace of mind that their freezers, refrigerators and walk-ins are functioning 24/7, monitored from a customizable dashboard to prevent spoilage and loss.

When you couple the real-time monitoring with Sonicu’s ability to deliver automated compliance reports for federal, state and local agencies, Piazza has invested in an affordable and simple solution that helps them operate smarter and safer.

As the FDA continues to update the Food Traceability List and integrate its Food Safety Blueprint, Sonicu ensures that Piazza meets regulatory safety requirements with digital monitoring and paper back-ups.

The benefits of the Sonicu temperature monitoring system for Piazza and other food service providers include

asset protection (including alerts when a freezer malfunctions)

compliance automation to produce simple reports meeting local/state/federal regulations and compliance

and operational efficiency for less manual data captures and temps/conditions reporting

Global Food Safety Initiative Standards

Sonicu’s temperature monitoring system supports stakeholders at Piazza Produce, a Safe Quality Foods Institute SQF Level II Certified Company, by helping them meet and exceed Global Food Safety Initiative (GFSI) standards.

The GFSI is an international action group from The Consumer Goods Forum launched in 2000 as a non-profit.

It is composed of 42 retailers and manufacturers collaborating as a food safety oversight community to drive positive change through action.

The initiative establishes and maintains standards for businesses and helps provide access to safe food worldwide.

Here in the U.S., Sonicu wireless temperature monitoring helps local food service providers and businesses such as Piazza Produce, and others, streamline their operations and make regulatory compliance reporting simple.

Wireless temperature monitoring helps keep consumers safe by preventing spoilage and better navigating compliance audits.

This is achieved through constant temperature monitoring for freezers, refrigerators, walk-in coolers, cold warehouses and transport.

Farming Food Chain Safety

Sonicu’s advanced software capabilities also provide farm-to-table food traceability and production safety for Tyner Pond Farms, a 500-acre beef, pork chicken and turkey farm located in Greenfield, Ind.

The farm is dedicated to natural, pasture-raised livestock and sustainable farming, as well as transparent food traceability and smarter food safety.

Thanks to 24/7 automated remote monitoring, any potential threats to consumer safety and wellness from freezer failure due to power outages, human error and erratic performance can be easily and continuously detected.

To establish remote monitoring access onsite at Tyner Pond, Sonicu performed an assessment based on a demanding need for data-driven process controls and alarm notifications for temperature excursions on its meat freezers.

The days of tirelessly checking on equipment based on a hunch or bad feeling would soon be replaced with the insurance of state-of-the-art technology.

This helps Tyner Pond fulfill its mission of “providing grass-fed beef, local pork, pasture -raised chicken and turkey unmatched in quality and nutrition by using regenerative farming practices.”

The Natural Resources Defense Council (NRDC) defines the regenerative farming philosophy as an approach to land management that considers all aspects of agriculture connected as a network of entities rather than a linear supply chain.

This network grows, enhances, exchanges, distributes and consumes goods and services using holistic principles to restore soil and ecosystem health by considering the future of the land, waters and climate.

This philosophy, says the NRDC, benefits the health of farmers, farmworkers, and downstream communities by reducing use of and exposure to harmful chemicals. That supports global food safety in the farming food chain.

“When we speak with farmers and ranchers focused on regenerative agriculture, they tell us that their notion of ‘success’ goes beyond yield and farm size,” said Lara Bryant, NRDC deputy director of water and agriculture, in the “Regenerative Agriculture 101” guide available online.

“It includes things like joy and happiness, the number of families they feed, watching how the land regenerates and flourishes, the money saved from not purchasing chemical inputs, the debt avoided by repurposing old equipment, and the relationships built with community members,” Bryant said.

Tyner Pond Farms made it a goal to start with tangible agrifood safety on a local level. That begins with improving soil health and building and strengthening the local community by providing drug-free humanely-raised animals to consumers.

Regenerative farmers such as Tyner Pond Farms make growing healthy food for their families and communities a priority.

This all ties back to the importance of food traceability and transparency, as well as smarter food safety for consumers.

Sonicu was quick to help in providing an affordable and intuitive solution by installing a temperature probe and transmitter assembly programmed to broadcast data and updates via Wi-Fi.

Technology in motion for an age-old agriculture philosophy that dates back centuries.

Sonicu’s alarms with predictive algorithms could now spot Tyner’s meat freezer trends, reduce alarm fatigue, and escalate if needed.

Employees now receive instant, automated notifications of freezer performance variances to protect inventory and save time, money and effort.

Web-based access is available to them by phone, tablet and PC, 24/7, on the user-friendly SoniCloud Monitoring Dashboard.

This modern, scalable platform easily allows for viewing and monitoring anytime with best-in-class security and reliability.

The system’s DataSync feature ensures data integrity, and cellular VPN eliminates security breach concerns.

All-digital temperature probes provide easy recalibration with Sonicu's SNAP calibration program. These features provide a level of security and compliance the farm had not experienced in its past.

A Culture of Food Safety

From agriculture to food service distributors, such on-demand quality control and regulatory compliance are ensured with Sonicu’s 24/7/365 monitoring and data storage solutions.

Services also include humidity monitoring for proper storage, air pressure monitoring for critical areas, and power and machine-to-machine monitoring to maintain efficiency and lean manufacturing processes.

Sonicu allows for full-service operational management with superior operational visibility from a single platform.

This helps the FDA fulfill its promise to “foster, support and strengthen food safety cultures on farms, in food facilities, and in homes.”

The FDA says it will not “make dramatic improvements in reducing the burden of foodborne disease without doing more to influence the beliefs, attitudes, and, most importantly, the behaviors of people and the actions of organizations.”

The Michigan State University Extension reports that the changing mindset within the food safety culture continues to evolve.

According to the MSU Extension, food safety culture starts with looking at produce, and how it is handled in the operation, as food.

“It is very easy when handling bulk volumes of fruits or vegetables to think of it as a commodity, like corn or soybeans. By thinking of the produce as food, a culture of food safety begins.”

The Extension reminds us that fresh produce interactions, from harvest to distribution, impacts quality and safety. Understanding and evaluating food flow in this context is the next step in developing a culture of food safety, says the Extension.

“Whether it is recognizing that the holding temperature of the cooler is important, or understanding that healthy workers harvest and pack safe food, these realizations will begin to inform management decisions that drive change on the farm.”

Sonicu wholeheartedly agrees.

We believe our commitment to improving and promoting food safety shows in the affordability and simplicity of the products and technology we implement.

American-based Customer Support: Robust & Reliable High Touch Service

Software and technology is only as good as the people who stand behind it.

At Sonicu, that means our team of American-based customer success managers who are never more than a phone call away to help field and fix any service issues.

Our probes and sensors are placed in demanding frozen environments and our software literally sends billions bits of data monthly, meaning there’s alway the potential for a hiccup on either the hardware or software.

We are committed to fielding every customer service request promptly and addressing our customer’s concerns promptly and professionally.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director