Heat Stress Monitoring Technology

If you are looking for heat stress monitoring technology that helps you and your team eliminate manual logging, improve compliance readiness, and protect all your temperature-sensitive assets, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts via text, email, push notifications and phone calls to protect your precious assets

- Compliance: Automated compliance reports

- Efficiency: Reduced Manual Logging and time spent on reports

- Robust Redundancy: Battery Backup and DataSync for reliable data continuity

And what makes us different?

- Lifetime Warranty: Ongoing warranty included with monitoring subscription

- Unlimited Users: Scale across your entire organization

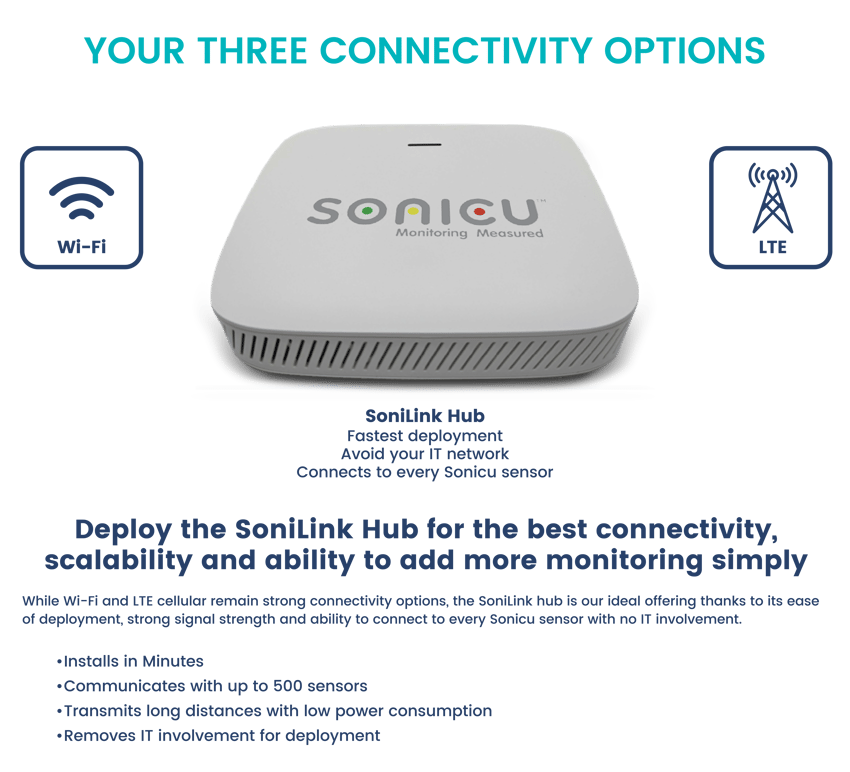

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

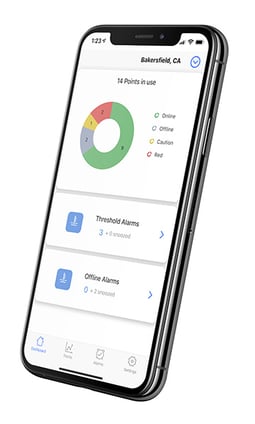

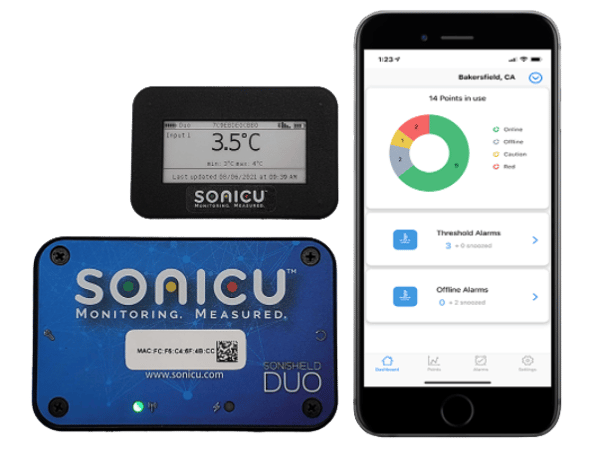

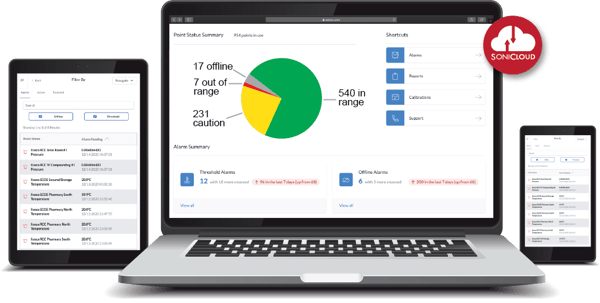

- Mobile App: 500 Freezers in your pocket

- Facility monitoring: Simple to add water leak, door open, occupancy, and even IAQ monitoring

Engineered in Indiana with U.S.-based support.

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

Warehouse Monitoring

Sonicu’s sensors and automated systems detect patterns of overcooling or overheating, enabling precise adjustments that reduce energy consumption without sacrificing product quality. The result? A remarkable reduction in operational costs and a commendable contribution to sustainability efforts.

Warehouse Monitoring Brochure

Understanding and Preventing Heat Stress Demo

Learn how to recognize, prevent, and manage heat stress in outdoor or high-heat work conditions. This video highlights essential safety measures, symptoms to watch for, and practical tips to protect yourself or your team from heat-related illnesses. Perfect for construction workers, outdoor professionals, and anyone working in extreme temperatures. Stay safe, stay productive!

Heat Stress Monitoring Systems

As temperatures continue to rise globally, the need for effective heat stress monitoring in workplaces has become increasingly important.

Prolonged exposure to high temperatures can cause heat-related illnesses such as heat exhaustion, heat stroke, and dehydration, all of which can significantly impact worker health and productivity.

Industries that operate in enclosed environments, such as warehouses, factories, food processing facilities, and healthcare centers, are particularly vulnerable to the dangers of indoor heat stress.

In response to these challenges, the Occupational Safety and Health Administration (OSHA) has proposed new rules to address heat stress for indoor workers.

These regulations aim to protect employees from heat-related risks by enforcing temperature management and monitoring standards in workplace environments.

Cal/OSHA's Heat Illness Prevention in Indoor Places of Employment regulation applies to most indoor workplaces, such as restaurants, warehouses, and manufacturing facilities where temperatures can get high.

For indoor workplaces where the temperature reaches 82 degrees Fahrenheit, employers must take steps to protect workers from heat illness.

Some of the requirements include providing water, rest, cool-down areas, methods for cooling down the work areas under certain conditions, and training.

Employers may be covered under both the indoor and outdoor regulations if they have both indoor and outdoor workplaces.

Sonicu has extensive experience in this area, having successfully implemented similar solutions for several clients in California, where CAL/OSHA has been a pioneer in these regulations.

Sonicu is a trusted partner for organizations that prioritize compliance, and we are well-equipped to meet your regulatory needs.

IoT-based heat stress monitoring systems like those from Sonicu are playing an increasingly vital role in helping companies comply with these rules, providing a range of benefits from real-time data collection to predictive analytics.

Sonicu helps companies manage the risk of heat stress by delivering affordable and simple heat stress monitoring technology that employers can deploy rapidly and keep track of their heat stress situation from virtually anywhere.

Thermal environment monitors, for instance, are devoted to the measurement of heat.

Therefore, they overlap quite a lot with heat stress monitoring equipment and other types of temperature monitoring devices.

A business or organization may understand the need to use thermal environmental monitoring, but they still may struggle with how to use thermal environment monitoring.

That is why many businesses turn to the wireless technology of Sonicu’s remoting heat stress monitoring system.

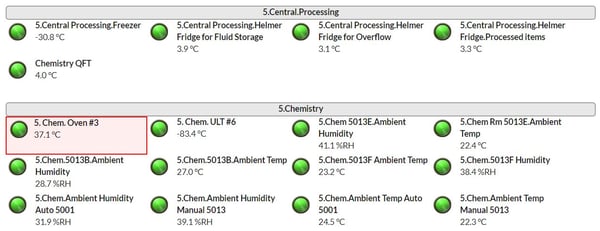

With Sonicu, the thermal monitor manual is easy to digest, and the system has a user-friendly dashboard and interface to make heat stress monitoring as easy and efficient as it can be.

These are some of the reasons why businesses turn to wireless thermal environmental monitoring.

- Operational Efficiency: Virtually eliminate the need for tedious and costly manual logging

- Compliance Automation: Respond to virtually any regulatory audit or inspection in a few clicks with our reports section

- People Protection: Detect and respond to temperatures deemed too high by regulators so you can protect your employees from heat-related injuries

Rather than constantly having to manually log in data, a supervisor can place the settings wherever they want them and trust that the system will alert them should there be any deviation from the desired temperature or other climate conditions.

Sonicu offers more than a year of data storage for your logs, and our sensors are completely wireless, cost-effective, and easy to deploy.

Our alerting system is highly customizable, providing notifications via text, email, phone calls, and push notifications.

These alerts can be configured to repeat and escalate, ensuring that the appropriate personnel are promptly informed and can take necessary action.

Sonicu sensors are compact, resembling hockey pucks in size and shape, and are IP67-rated for durability. They measure both ambient temperature and humidity, with our cloud-based software automatically calculating the heat index.

Sonicu software also offers sophisticated multi-site management features, enabling you to efficiently oversee multiple divisions.

You can learn more about how Sonicu software helps compliance professionals in these case studies:

Hamilton County, Indiana Health Department: Vaccine Monitoring

Problem: The need to protect vaccines from temperature excursions and meet state compliance requirements with an outdated analog system.

Solution: Implemented a new monitoring system with a mobile app and robust support, enhancing the management of remote COVID-19 vaccination programs.

Katherine Shaw Bethea Hospital: Pharmacy Monitoring for Remote Clinics

Problem: After a freezer failure led to a loss of drugs, the pharmacy director needed a reliable and simple monitoring solution for multiple remote clinics.

Solution: Adopted Sonicu's temperature monitoring system, enhancing audit readiness, and deploying a mobile app to employees across clinics in Illinois.

Nomi Health: Fast installation, simple deployment

Problem: A rapidly growing healthcare technology startup needed to scale quickly and monitor cold chain storage devices nationwide.

Solution: Implement Sonicu's temperature probes with a central command center for enterprise visibility, allowing fast and easy training for reps across the country.

This article explores the value of IoT-based heat stress monitoring systems, particularly in light of OSHA’s proposed regulations, and how these systems contribute to safer, more efficient workplace environments.

The Heat Stress Problem in Indoor Workplaces

Indoor workers across various industries often face significant heat-related risks, especially in enclosed environments where temperatures can rise dramatically.

Heat stress can result from a combination of factors, including high ambient temperatures, poor ventilation, humidity, and the heat generated by machinery and equipment.

When indoor temperatures soar, workers are at an increased risk of developing heat-related illnesses, which can lead to lost productivity, increased absenteeism, and even serious health emergencies.

Industries such as manufacturing, food services, healthcare, and warehousing are particularly susceptible to the hazards of indoor heat stress.

Workers in these environments often perform physically demanding tasks, further elevating their susceptibility to heat stress.

Additionally, the use of heavy machinery and industrial processes can exacerbate the problem by increasing both temperature and humidity levels inside the workspace.

OSHA’s proposed rules on indoor heat stress are designed to address these challenges by requiring employers to implement measures that safeguard workers from excessive heat exposure.

These regulations emphasize the need for continuous monitoring of environmental conditions, ensuring that workers are not exposed to unsafe temperatures.

IoT-based heat stress monitoring systems, like those from Sonicu, are uniquely positioned to help businesses meet these requirements, providing real-time data that enables timely interventions and informed decision-making.

The Sonicu Ambient Temperature solution can help ensure that the OSHA heat safety requirements are met in your facility.

Combining wireless sensors with remote monitoring software, the smart solution measures humidity and temperature in critical environments, including warehouses, distribution centers, depots, processing plants, and kitchens.

The Sonicu Facility Monitoring solution sends a real-time alert so you can take prompt remedial action to prevent heat-related sickness.

How IoT-Based Heat Stress Monitoring Systems Work

IoT-based heat stress monitoring systems use interconnected sensors and cloud-based platforms to measure environmental conditions such as temperature, humidity, and air quality in real time.

These sensors are strategically placed throughout the workplace to collect data from different areas, ensuring comprehensive monitoring of the indoor environment.

The data is then transmitted to a centralized dashboard, where it is analyzed to identify potential heat stress risks.

One of the most significant advantages of IoT technology is its ability to provide continuous, real-time monitoring.

Unlike traditional methods that rely on manual checks or sporadic temperature measurements, IoT-based systems like those offered by Sonicu ensure that environmental conditions are monitored 24/7.

If temperatures or humidity levels exceed safe thresholds, the system automatically triggers alerts, notifying supervisors and management teams of the potential risk.

This immediate response allows for quick interventions, such as adjusting ventilation systems, increasing hydration breaks, or altering work schedules to reduce heat exposure.

Beyond real-time monitoring, IoT-based heat stress systems also leverage predictive analytics to forecast future heat stress risks.

By analyzing historical data and environmental trends, these systems can anticipate when heat stress levels are likely to become dangerous, allowing companies to take proactive measures to protect their workers.

This predictive capability is especially valuable for businesses that operate in climates where temperatures can fluctuate rapidly or during seasonal periods of extreme heat.

OSHA’s Proposed Rules on Heat Stress and the Role of IoT

The proposed new OSHA regulations on indoor heat stress reflect a growing recognition of the dangers posed by extreme temperatures in the workplace.

Under these rules, employers would be required to implement a range of safety measures designed to prevent heat-related illnesses.

These measures include establishing maximum allowable temperature thresholds, providing adequate ventilation, and ensuring that workers have access to cool areas and hydration.

One of the key components of OSHA’s proposed regulations is the requirement for continuous monitoring of workplace temperatures.

This is where IoT-based heat stress monitoring systems like those from Sonicu play a crucial role.

By providing real-time data on environmental conditions, these systems enable businesses to meet OSHA’s monitoring requirements efficiently and accurately.

The ability to track temperature and humidity in real-time ensures that employers can identify potential risks before they become serious, preventing heat-related illnesses and ensuring compliance with regulatory standards.

Furthermore, IoT-based systems like Sonicu’s offer detailed data logs that can be used to demonstrate compliance with OSHA’s rules.

In the event of an inspection or audit, companies can provide records showing that they have actively monitored heat stress levels and taken appropriate actions to safeguard their workers. This level of transparency is invaluable for businesses looking to avoid fines, penalties, or legal actions associated with non-compliance.

The Value of IoT Heat Stress Monitoring in Warehouses

Warehouses are one of the industries most affected by indoor heat stress.

These large, enclosed spaces often lack sufficient ventilation, leading to rising temperatures, especially during hot summer months.

Workers in warehouses frequently engage in physically demanding tasks such as loading, unloading, and operating machinery, all of which increase the risk of heat-related illnesses.

IoT-based heat stress monitoring systems, including those from Sonicu, are particularly valuable in warehouse environments because they allow for localized monitoring of temperature and humidity levels.

In a large warehouse, environmental conditions can vary significantly from one area to another. For instance, areas near loading docks or machinery may experience higher temperatures than other parts of the facility.

By placing IoT sensors throughout the warehouse, managers can gain real-time insights into the specific areas where heat stress is most likely to occur.

In addition to providing real-time data, IoT systems help warehouse managers optimize their ventilation and cooling systems.

When heat stress thresholds are exceeded, the system can automatically trigger actions such as activating fans, opening vents, or adjusting air conditioning systems.

This not only protects workers from heat exposure but also ensures that the warehouse remains a productive and efficient environment.

Last year, two warehouse operators called Sonicu for indoor temperature monitoring after their warehouse facility failed to comply with OSHA standards for indoor heat stress.

We’re helping them install flexible and affordable indoor temperature monitoring that is cloud-based, redundant, and delivers real-time, continuous monitoring via any connected device to help your team stay on the right side of regulators and inspectors.

"These new policies are meant to protect employees from heat stress and can also protect employers from punitive fines and damages related to noncompliance,” said Joe Mundell, Chief Revenue Officer, Sonicu.

“We’re pleased to offer simple solutions that are affordable and easy to buy and install via our e-commerce platform.

“You’ll know you have a temperature monitor trusted by the finest names in healthcare that can also protect your facility from running afoul of new stringent OSHA heat stress standards.”

IoT and Heat Stress Monitoring in the Food Service Industry

The food service industry faces unique challenges when it comes to managing heat stress. Commercial kitchens, food processing plants, and storage facilities are often high-heat environments where workers are exposed to ovens, fryers, and other cooking equipment that generate significant amounts of heat.

These conditions, combined with the physical demands of preparing and handling food, make heat stress a serious concern for food service employees.

IoT-based heat stress monitoring systems, like those from Sonicu, provide a critical solution for food service businesses looking to protect their workers from the dangers of heat exposure.

In commercial kitchens, IoT sensors can monitor temperature and humidity levels in real-time, ensuring that environmental conditions remain within safe limits.

If temperatures rise to dangerous levels, the system can alert kitchen staff and management, allowing them to implement immediate interventions such as adjusting ventilation or providing additional breaks.

For food processing facilities, where temperature control is essential not only for worker safety but also for food safety, IoT systems offer an additional layer of protection.

By continuously monitoring environmental conditions, these systems help ensure that food products are stored and handled at appropriate temperatures, preventing spoilage or contamination.

This dual benefit of protecting both workers and food products makes IoT heat stress monitoring an invaluable tool for the food service industry.

Enhancing Safety in Healthcare Facilities with IoT Heat Stress Monitoring

Healthcare facilities, including hospitals, nursing homes, and outpatient clinics, are environments where maintaining safe and comfortable temperatures is essential for both patient care and worker safety.

While these facilities are typically climate-controlled, certain areas may still experience elevated temperatures due to equipment use, poor ventilation, or overcrowding.

Workers in healthcare settings, such as nurses, doctors, and support staff, are often required to wear personal protective equipment (PPE) that can exacerbate heat stress in already warm environments.

IoT-based heat stress monitoring systems provide healthcare facilities with the tools they need to maintain a safe environment for both staff and patients.

These systems can be installed in critical areas such as operating rooms, intensive care units, and boiler rooms, where temperature fluctuations are more likely to occur.

By continuously monitoring environmental conditions, healthcare managers can ensure that heat stress risks are minimized, reducing the likelihood of heat-related illnesses among staff members.

In addition to protecting workers, IoT heat stress monitoring systems help safeguard the integrity of medical equipment, medications, and temperature-sensitive supplies.

Many medical devices and pharmaceutical products must be stored within specific temperature ranges to remain effective.

IoT systems can detect fluctuations in environmental conditions and alert facility managers to take corrective actions before critical equipment or supplies are compromised.

The Role of IoT in Pharmacies and Pharmaceutical Facilities

Pharmacies and pharmaceutical manufacturing facilities are another sector where IoT-based heat stress monitoring systems are making a significant impact.

In these environments, both worker safety and product integrity depend on maintaining strict temperature control.

Heat stress poses a risk to employees who work in production areas where machinery generates heat, and temperature fluctuations can also affect the quality and safety of pharmaceutical products.

IoT-based heat stress monitoring systems help pharmaceutical facilities maintain safe working conditions by providing real-time data on temperature and humidity levels.

In production areas, these systems can alert supervisors when environmental conditions become unsafe, allowing them to adjust ventilation, modify work schedules, or implement other interventions to reduce heat exposure.

This proactive approach minimizes the risk of heat-related illnesses among workers, ensuring that the facility remains a safe and productive environment.

For pharmacies, where temperature-sensitive medications must be stored within specific ranges, IoT systems provide an additional level of protection.

By continuously monitoring storage conditions, these systems help ensure that medications are not exposed to extreme temperatures that could compromise their efficacy.

This is particularly important for medications like vaccines, insulin, and biologics, which require precise temperature control to remain effective.

IoT-Based Heat Stress Monitoring Across Other Industries

While industries such as warehousing, food services, healthcare, and pharmaceuticals are particularly vulnerable to heat stress, IoT-based monitoring systems have applications across a wide range of sectors.

In manufacturing, construction, and energy production, workers often operate in high-heat environments that can lead to heat-related illnesses.

IoT systems offer a cost-effective solution for monitoring these conditions, enabling companies to protect their workers and comply with regulatory requirements.

In office environments, particularly those located in regions prone to extreme heat, IoT systems can be used to monitor indoor air quality and temperature, ensuring that employees remain comfortable and productive.

By integrating IoT technology into their workplace safety protocols, businesses across all industries can create safer, more resilient work environments that prioritize employee well-being.

Conclusion

As OSHA moves forward with its proposed new rules on indoor heat stress, businesses across various industries must take proactive steps to protect their workers from the dangers of excessive heat exposure.

IoT-based heat stress monitoring systems provide a powerful solution for meeting these regulatory requirements, offering real-time data, predictive analytics, and automated alerts that enable companies to maintain safe working conditions.

By adopting IoT-based heat stress monitoring systems, businesses can not only ensure compliance with OSHA regulations but also reduce the risk of heat-related illnesses, improve productivity, and foster a culture of safety in the workplace.

As global temperatures continue to rise, systems like those offered by Sonicu will play an increasingly important role in safeguarding both workers and operations from the hazards of heat stress.

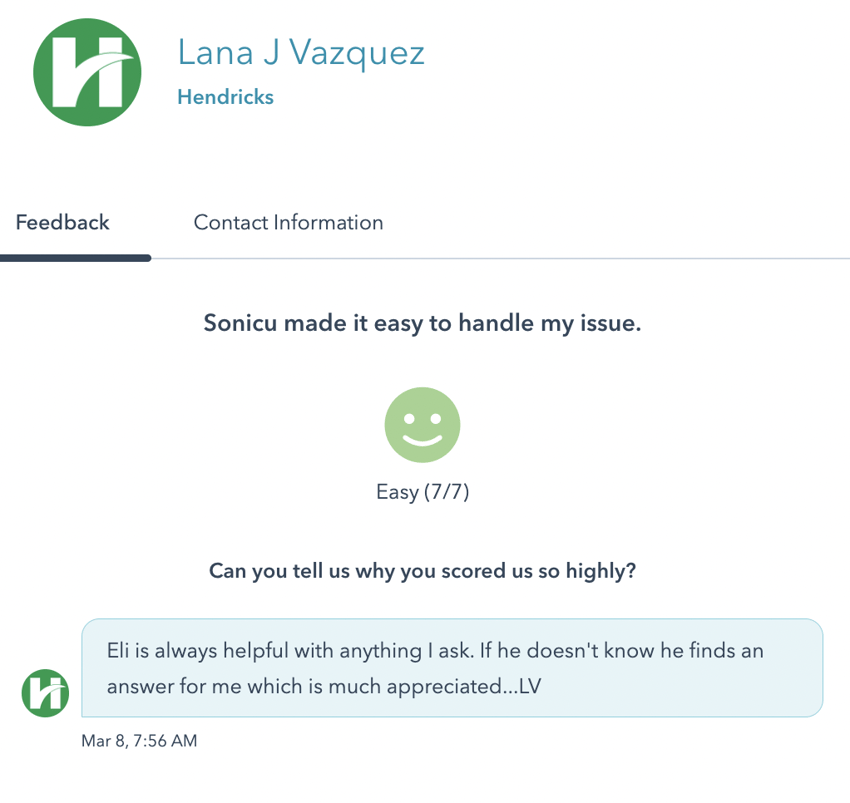

American-based Customer Support: Robust & Reliable High Touch Service

Software and technology is only as good as the people who stand behind it.

At Sonicu, that means our team of American-based customer success managers who are never more than a phone call away to help field and fix any service issues.

Our probes and sensors are placed in demanding frozen environments and our software literally sends billions bits of data monthly, meaning there’s always the potential for a hiccup on either the hardware or software.

We are committed to fielding every customer service request promptly and addressing our customer’s concerns promptly and professionally.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

How IU Health

consolidated all of its pharmacy monitoring needs

into one cloud-based platform serving dozen of locations.