K-12 Food Safety Temperature Device

If you are looking for a K-12 food safety temperature device that helps you and your team eliminate manual logging, improve compliance readiness, and protect all your temperature-sensitive assets, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts via text, email, push notifications and phone calls to protect your precious assets

- Compliance: Automated compliance reports

- Efficiency: Reduced Manual Logging and time spent on reports

And what makes us different?

- Lifetime Warranty: Never buy hardware again!

- Unlimited Users: Scale across your entire organization

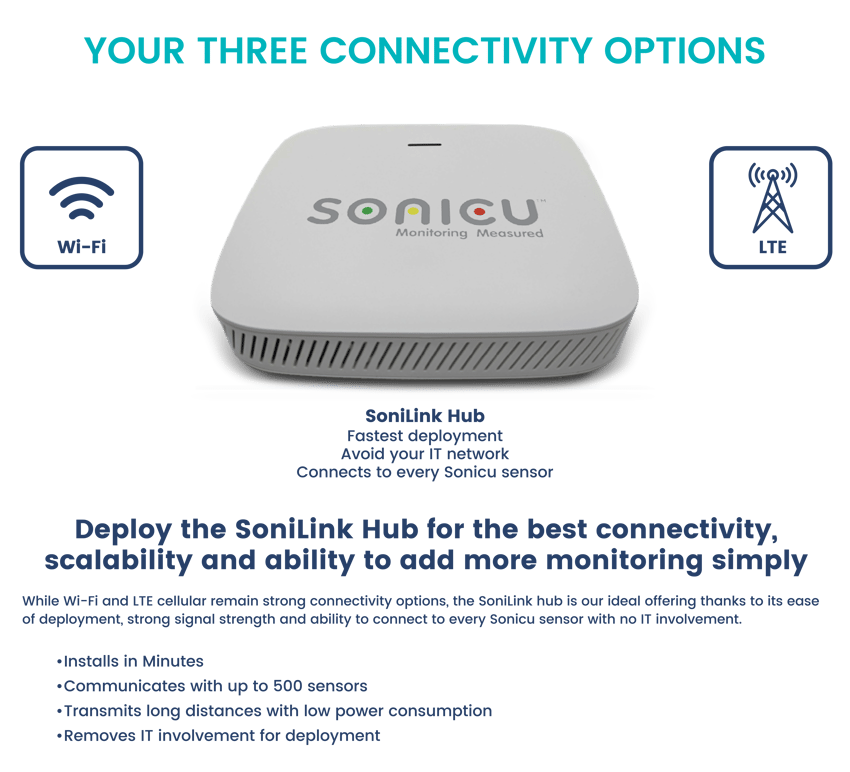

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

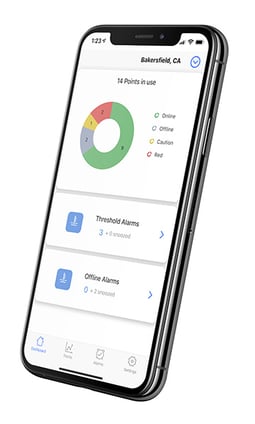

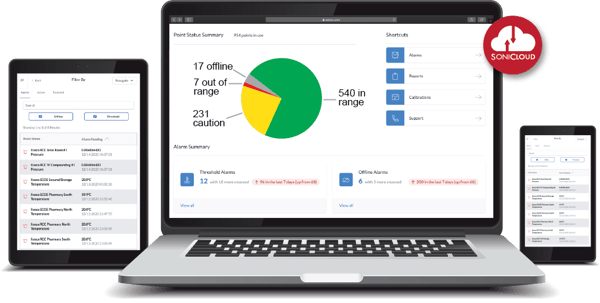

- Mobile App: 500 Freezers in your pocket

- Facility monitoring: Simple to add water leak, door open, occupancy, and even IAQ monitoring

Engineered in Indiana with U.S.-based support.

K-12 Temperature Monitoring

Monitoring the environment in the cafeteria helps ensure food safety and prevent foodborne illnesses. Conditions such as temperature and humidity need to be monitored to maintain proper storage conditions for perishable food items.

K-12 Monitoring Brochure.png?width=2000&height=312&name=Food%20Trust%20Bar%20Logos%20(2).png)

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

Unlocking the Future of School Health: The Transformative Power of K-12 Food Safety Temperature Device Solutions

A K-12 food safety temperature device is a specialized instrument designed to monitor the temperature of food items in a K-12 school setting. K-12 refers to the kindergarten to twelfth-grade education system, encompassing a broad range of students typically aged from 5 to 18 years. These devices can come in various forms, such as digital thermometers, infrared scanners, and IoT-enabled temperature sensors that send real-time data to a central system.

In many jurisdictions, schools are required to comply with specific food safety standards, which often include temperature control. Failure to adhere to these standards can lead to legal issues, financial penalties, and reputational damage.

Ensuring the correct temperature for food storage and preparation is critical for minimizing the risk of foodborne illnesses. Young children are particularly susceptible to such illnesses, making temperature control even more crucial in a K-12 setting.

Proper temperature control reduces food spoilage, thereby minimizing waste and contributing to more sustainable operations.

Food that is stored and prepared at the right temperature is also more likely to taste better and have a better texture, thus improving the overall meal experience for students.

Automated or IoT-enabled temperature monitoring systems can also free up staff to focus on other essential tasks, streamlining kitchen operations and contributing to a more efficient learning environment.

Advanced systems that collect data over time can help school administrators make informed decisions about equipment upgrades, staffing needs, or menu changes.

Knowing that the school takes food safety seriously can be a significant selling point for parents when choosing a school for their children.

It could also serve as an educational tool, showing students the importance of food safety and possibly integrating it into subjects like home economics or science.

In the long term, investing in a reliable food safety temperature device can be more cost-effective by preventing food spoilage, avoiding health-related lawsuits, and improving operational efficiency.

Lastly, in case of power outages or equipment failures, real-time monitoring can alert staff immediately, allowing them to take quick corrective actions, thus averting potential crises.

A K-12 food safety temperature device is an indispensable tool that contributes significantly to the smooth running of educational institutions by ensuring compliance, improving health and safety, and enhancing operational efficiencies.

You can learn more about how our software helps compliance professionals in these case studies:

Xytex Sperm Bank: Ultra Low Temperature Monitoring

Problem: Frequent false alerts were causing alarm fatigue, threatening the operations at Xytex Sperm Bank.

Solution: Partnered with Sonicu to develop a custom temperature monitoring solution for ULT and cryo temperatures, including probes inside and outside the preservation chambers.

Boy Scouts: Protecting Campers from a Temperamental Walk-in Cooler

Problem: An aging walk-in cooler failed at a remote campground in Ohio, causing significant food loss and logistical challenges for the Boy Scouts.

Solution: Sonicu provided a system that was easy to install, connected with a mobile app, affordable for a non-profit budget, and automated the required manual logging.

Hamilton County, Indiana Health Department: Vaccine Monitoring

Problem: The need to protect vaccines from temperature excursions and meet state compliance requirements with an outdated analog system.

Solution: Implemented a new monitoring system with a mobile app and robust support, enhancing the management of remote COVID-19 vaccination programs.

Katherine Shaw Bethea Hospital: Pharmacy Monitoring for Remote Clinics

Problem: After a freezer failure led to a loss of drugs, the pharmacy director needed a reliable and simple monitoring solution for multiple remote clinics.

Solution: Adopted Sonicu's temperature monitoring system, enhancing audit readiness and deploying a mobile app to employees across clinics in Illinois.

What are the key components of an IoT K-12 food safety temperature device?

IoT (Internet of Things) enabled K-12 food safety temperature monitoring devices consist of several key components that work in harmony to ensure the efficient monitoring and regulation of temperature for food storage and preparation.

- Sensors

- Types of sensors can vary, including thermocouples, RTDs (Resistance Temperature Detectors), and thermistors.

- Microcontrollers

- These are the brains of the operation. They process the data received from the sensors and execute predefined actions based on the data.

- Connectivity modules

- Connectivity modules are responsible for connecting the device to a network. Options can include Wi-Fi, Ethernet, or cellular connectivity.

- Data storage

- Some systems come with onboard storage to save data, which can be useful for tracking trends over time or for compliance.

- User interface

- This is often a software platform, accessible via a web browser or mobile app, where administrators can monitor real-time data, receive alerts, and even adjust settings.

- Power source

- Depending on the setup, the device might be powered by an electrical outlet, batteries, or even energy-harvesting technologies like solar panels.

- Housings and enclosures

- These are designed to protect the internal components from environmental factors like moisture and extreme temperatures, ensuring the long-term reliability of the system.

- Alarm systems

- Alarm systems are either software or hardware-based components that trigger alerts (auditory, visual, or digital) when temperature readings move out of the defined safe range.

- Cloud computing

- Enables easier access to data and more straightforward integration with other systems like inventory management or school administration software.

- Edge computing

- Allows for quicker data processing on the device itself, reducing latency and improving response times.

- Low-Power Wide-Area Networks (LPWAN)

- These are used for devices that require long battery life and are situated in hard-to-reach areas, like inside large refrigerators.

- Big data analytics

- For the analysis of vast sets of data to find trends and make data-driven decisions.

- Real-Time operating systems (RTOS)

- To manage the real-time requirements of monitoring, controlling, and data logging in a reliable manner.

By leveraging these components and technologies, IoT-enabled K-12 food safety temperature monitoring devices provide a robust, reliable, and efficient system for ensuring that food storage and preparation meet required safety standards.

Asset Protection. Compliance Automation. And Reduced Manual Processes. Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

What are the pain points that a K-12 food safety temperature device effectively resolves?

IoT-enabled K-12 food safety temperature monitoring devices are specifically engineered to tackle some of the most persistent and challenging issues in food safety and operational efficiency in educational settings.

First, one of the most significant risks in manual temperature monitoring is human error, either in reading temperatures or recording them. Automated systems virtually eliminate this risk by taking consistent, accurate readings and storing them digitally.

Keeping meticulous records for compliance can be a tedious process. IoT devices simplify this by automatically logging temperature data and generating reports, thus making it easier to retrieve historical data during health inspections or audits.

The need for immediate action when temperatures go out of range is critical. Automated alert systems in IoT devices can notify staff instantly through multiple channels, such as emails or text messages, allowing for immediate corrective actions.

Staff can also be freed from the routine task of manual temperature checking, allowing them to focus on other aspects of food preparation and service. This increases productivity and reduces labor costs.

Especially important during off-hours, the remote monitoring capabilities also mean that temperature abnormalities can be identified and addressed even when no one is on-site.

As institutions grow or regulations change, updating a manual system can be cumbersome. IoT devices can also often be easily upgraded with software updates or scaled with the addition of new sensors.

The capability to gather and analyze data over time allows for predictive analytics. This feature can identify inefficient appliances that need replacement or alert administrators to seasonal trends that may require adjustments in storage practices.

Also, although the initial investment may be high, the long-term cost savings in terms of reduced waste, labor costs, and potential legal fees make these systems financially advantageous in the long run.

Ultimately, ensuring the health and safety of the students and staff can also significantly improve the reputation of an educational institution, making it more attractive to prospective students and their parents.

By addressing these pain points, IoT-enabled K-12 food safety temperature monitoring devices significantly improve the safety, efficiency, and compliance of food handling processes in educational institutions. They offer a multi-faceted solution that meets both regulatory requirements and operational needs, while also providing the data and analytics capabilities for continuous improvement.

Easy to install and configure and supported by live American-based phone support, Sonicu is the most affordable, intuitive, and trusted temperature and environmental monitoring solution nationwide.

Key Benefits of a K-12 Food Safety Temperature Device

- These devices offer high-precision temperature monitoring, reducing the risk of human error in readings.

- Data is automatically logged and can be easily retrieved, which is vital for compliance and audits.

- Real-time notifications allow for swift action when temperatures go out of range, reducing the risk of spoilage or foodborne illnesses.

- Automation frees staff from the task of manual temperature checking, allowing them to focus on other responsibilities.

- The capability to monitor the system from anywhere provides added flexibility and security, especially during off-hours.

- The system can be easily scaled up or down according to needs, either by adding more sensors or updating the software.

- Advanced systems can adaptively control energy usage in real-time, leading to reduced operational costs.

- The ability to collect and analyze extensive data sets offers insights for process improvement and predictive maintenance.

You can learn more about how our software helps compliance professionals in these case studies:

CleanSlate: Addiction Treatment Centers

Problem: A Boston-based addiction treatment center needed an affordable and simple monitoring solution for their facilities across the United States.

Solution: Choose Sonicu for its affordability and ease of self-installation, supporting the center's mission to manage growth and improve service delivery nationwide.

UHS: South Texas Health System, Edinburg

Problem: Fire alarm testing disrupted the environmental conditions in Operating Rooms, causing compliance and operational challenges.

Solution: Implemented Sonicu's environmental monitoring system, which allowed the facility manager to monitor conditions via a mobile app and resolve issues with the HVAC system triggered by fire alarms.

Exide Technologies: Advanced Compliance and Monitoring Solutions

Problem: Exide Technologies faced challenges with air quality management, needing to comply with stringent environmental health and safety regulations. Their legacy systems required manual logging and were not capable of providing the necessary real-time data for air pressure and quality monitoring.

Solution: Sonicu provided Exide with a mobile and flexible air pressure differential monitoring system that could be moved easily between locations as project conditions changed. This system offered continuous pressure data, real-time alerts for any deviations, and automated reporting that adhered to regulatory requirements, significantly reducing manual logging and enhancing operational efficiency.

Step Into the Future with Sonicu: Elevate Your School's Food Safety Standards Today

In the intricate ecosystem of K-12 education, safeguarding the health of our students is paramount. The cornerstone of that is ensuring the safety of the food they consume. With advancements in technology, traditional methods of monitoring food safety have been rapidly eclipsed by more innovative solutions, none more compelling than IoT-enabled K-12 food safety temperature monitoring devices.

From offering unmatched accuracy in temperature readings to eliminating the pitfalls of human error, these systems serve as an essential tool for every educational institution that prides itself on excellence and responsibility. They are not merely an investment in technology but a long-term investment in the health and safety of our students and the reputation of our schools.

Yes, there are challenges—initial costs, complexity, and the need for regular maintenance—but these are surmountable and pale in comparison to the host of benefits that such devices bring to the table. These include robust data analytics, real-time alerts, and automated record-keeping, which not only ensure compliance but also improve operational efficiency, making it a win-win for schools.

So, where do we go from here? If you're committed to offering an unparalleled educational experience that integrates not just quality education but also the highest standards of health and safety, it's time to take the next step.

Elevate the standards of your K-12 institution and become a trailblazer in adopting technology for a safer, more efficient operation. Invest in Sonicu's range of K-12 food safety temperature devices. Because at the end of the day, the safety of our children is a responsibility that we cannot afford to compromise.

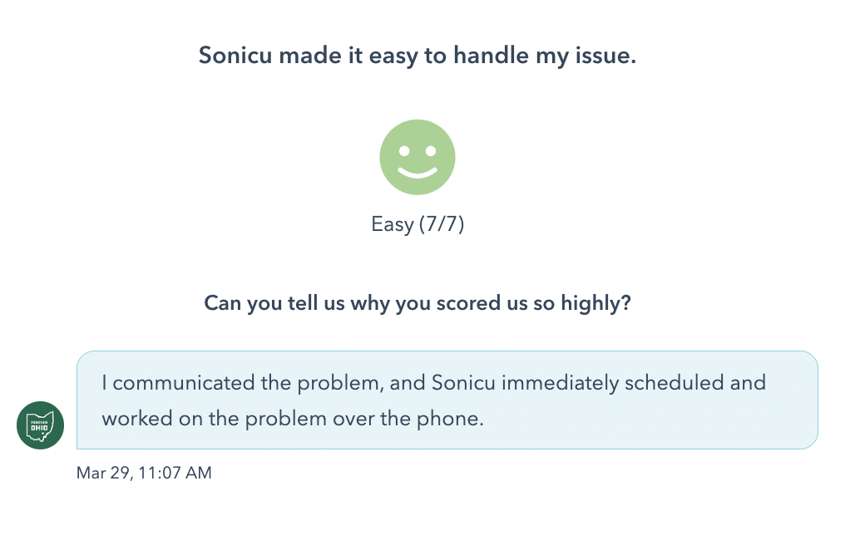

American-based Customer Support: Robust & Reliable High Touch Service

Software and technology is only as good as the people who stand behind it.

At Sonicu, that means our team of American-based customer success managers who are never more than a phone call away to help field and fix any service issues.

Our probes and sensors are placed in demanding frozen environments and our software literally sends billions bits of data monthly, meaning there’s always the potential for a hiccup on either the hardware or software.

We are committed to fielding every customer service request promptly and addressing our customer’s concerns promptly and professionally.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

How IU Health

consolidated all of its pharmacy monitoring needs

into one cloud-based platform serving dozen of locations.