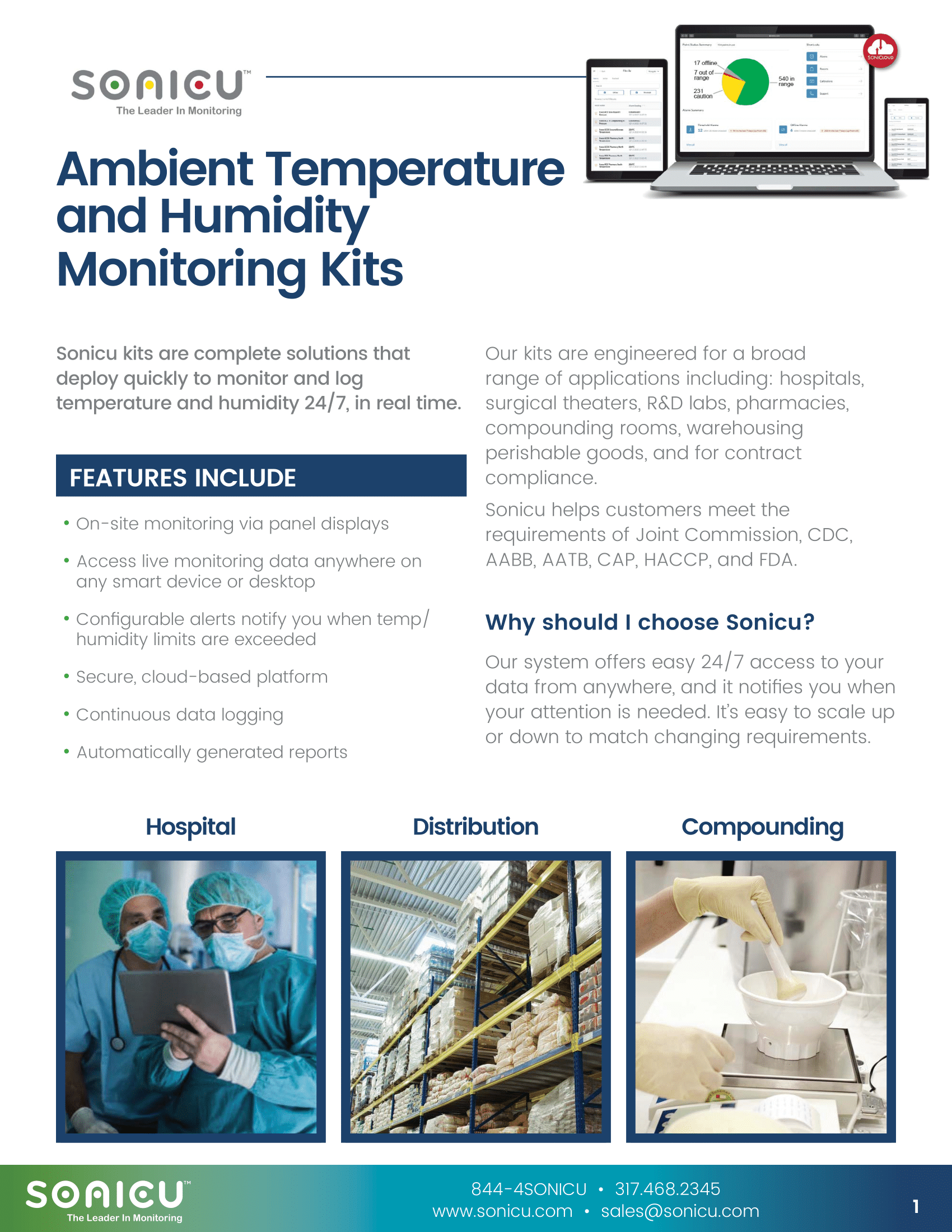

Ambient Temp & Humidity Monitoring

Monitor both temperature and humidity with a single sensor.

Designed with safety, efficiency and compliance always top of mind, we’ve evolved over a decade with continuous improvements from customer feedback. Serving the healthcare, research and food service industries.

Sonicu offers a comprehensive suite of monitoring solutions

that help organizations safeguard assets, automate compliance and reduce manual processes.

Sonicu offers a comprehensive suite of monitoring solutions

that help organizations safeguard assets, automate compliance and reduce manual processes.

From protecting vaccines and research materials to safeguarding food service and facility operations, Sonicu’s monitoring applications cover temperature, humidity, pressure, and more. Whether you’re in healthcare, life sciences, food safety, or other industries, Sonicu provides visibility, compliance, and peace of mind across all your critical applications.

Understanding Heat Stress and OSHA Regulations: How to Protect Your Employees and Ensure Compliance

Sonicu’s all-in-one monitoring kits are designed for fast, hassle-free implementation requiring no tools or technical expertise. Each kit includes mounting and installation materials, along with a QR code that launches our mobile app-powered setup wizard to guide anyone through a simple step-by-step installation. With preconfigured, plug-and-play sensors, you can protect assets, automate compliance, and get monitoring in place in minutes.

Every Sonicu Monitoring Kit is built around the SoniShield Duo, paired with the sensors you need for your specific environment. Whether you’re safeguarding vaccines, food, research materials, or facility operations, each kit comes ready to deploy with simple installation, seamless connectivity, and 24/7 monitoring.

Browse our kits to find the right sensor application to keep your organization compliant and your critical assets protected.