Oxygen Monitoring

Protect your property from the devastating effects of oxygen depletion with our wireless O2 sensor system. Ideal for LN2 Storage in labs.

Our O2 sensors utilize advanced technology to detect and monitor oxygen levels, ensuring the safety and well-being of your environment.

With flexible connectivity options, these sensors promptly report any potential threats, providing real-time alerts that can be customized to meet the specific requirements of your organization.

University

Designed to ensure precise and continuous oxygen level monitoring, Sonicu's advanced oxygen sensor is a game-changer for universities and research facilities. By proactively monitoring oxygen levels, you can prevent depletion and preserve the integrity of critical environments where sensitive processes take place.

Clean Rooms

Protect patients, sensitive environments, and critical infrastructure with oxygen monitoring systems that help maintain optimal oxygen levels and preserve safety. Safeguard against oxygen depletion or excess by ensuring immediate detection and response to deviations, preventing potential risks to individuals and processes.

Ensure Safety and Optimal Oxygen Levels

Sonicu's advanced O2 sensor ensures round-the-clock monitoring of oxygen levels to maintain a safe and controlled environment.

Our O2 sensor is designed to provide accurate and reliable measurements, giving you peace of mind knowing that oxygen levels are within the desired range.

Oxygen Monitoring is ideal for:

- Cleanrooms

- Commercial Buildings

- Hospitals

- Pharmacies

- Research Facilities

- Server Rooms

- Warehouse and Supply Chain Management

Sonicu Keeps You One Step Ahead of Fluctuating Oxygen Levels

Don't wait until it's too late, take preventive measures to protect your business and equipment.

An O2 sensor is crucial for the early detection of various issues related to combustion, air quality, and safety. By monitoring the oxygen levels in different applications, it can alert you to potential problems before they escalate.

Our state-of-the-art sensor technology and real-time monitoring systems are designed to deliver alerts via call, text, email, and push notifications.

Safety. Simplified.

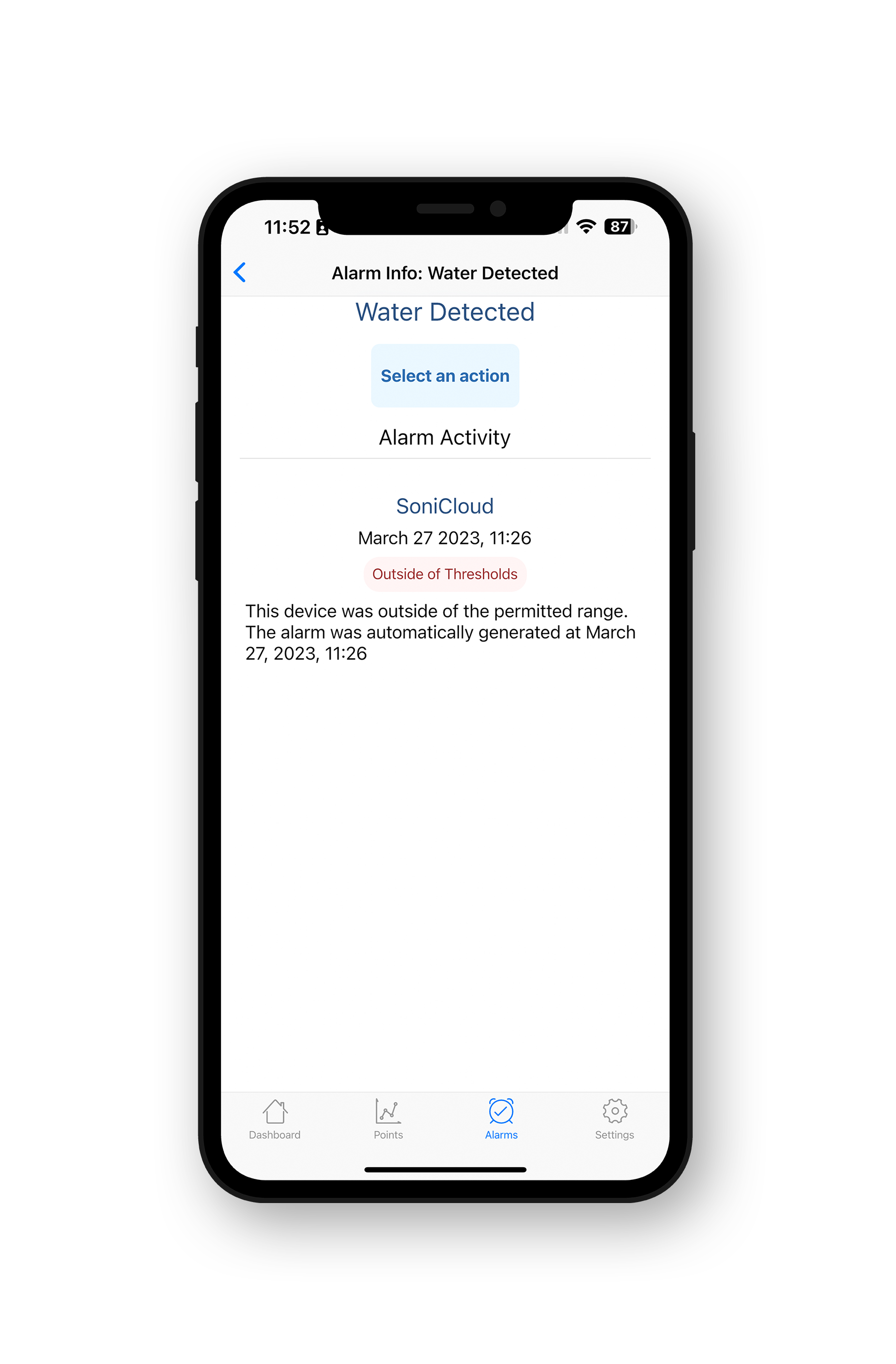

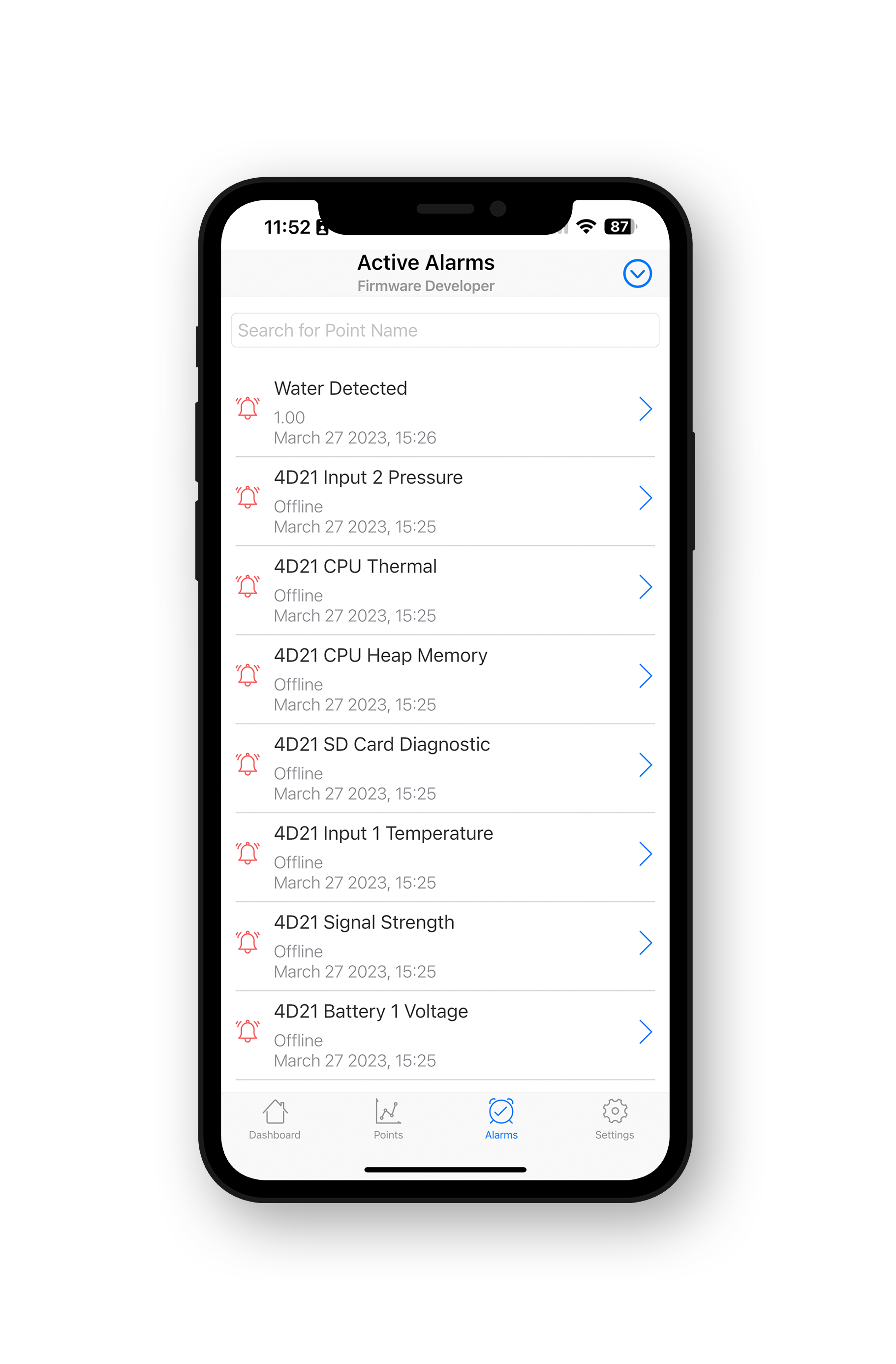

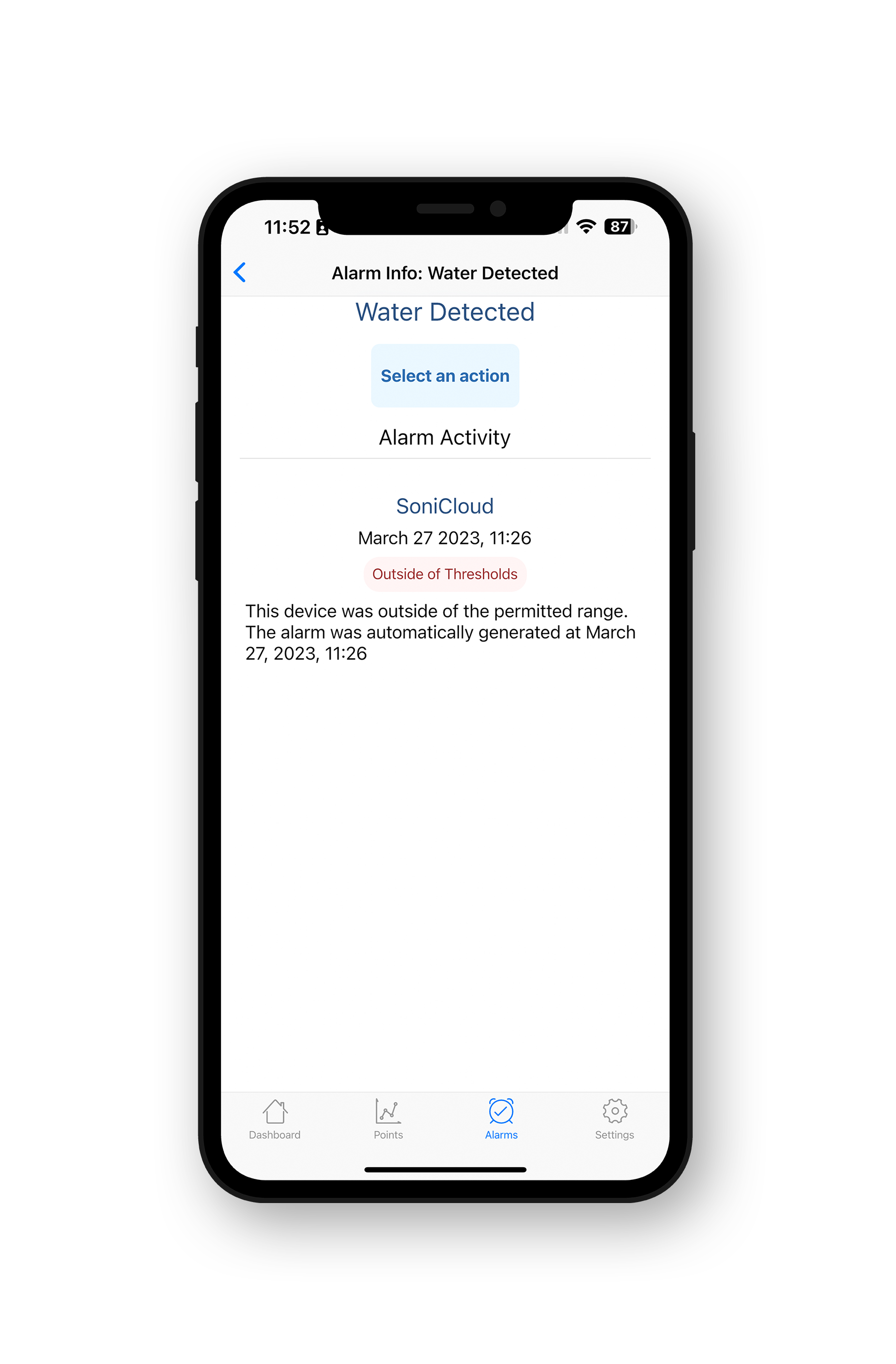

Sonicu's alarm system allows you to handle any alert directly from a computer, tablet, or smartphone.

Effortlessly handle comments, resolve issues, and snooze alerts with the user-friendly SoniCloud mobile app.

Oxygen Monitoring. Streamlined.

Sonicu Mobile App displays an alarm dashboard for oxygen monitoring. The dashboard display shows the status of each alarm.

The dashboard allows users to quickly identify any areas that are experiencing alarm conditions. This information is critical for maintaining safety and regulatory compliance.

Oxygen Monitoring. SoniCloud Simplified.

Using the SoniCloud Mobile App or SoniCloud Dashboard you have the option to view the data of one point of monitoring.

You can view the specific point of monitoring and its history with easy views that can be broken down by categories of Hour, Day, Week, and Month. Simplifying and fast-tracking any regulations you need to meet.

FAQ: Oxygen Monitoring Solutions by Sonicu

Why is oxygen monitoring important in various settings?

Oxygen monitoring is crucial in ensuring the safety and well-being of individuals, as well as maintaining optimal conditions in critical environments. It helps prevent oxygen depletion or excess levels, which can pose significant risks and impact the performance of sensitive processes.

How does Sonicu's system ensure real-time monitoring?

Our monitoring system operates in real-time, continuously analyzing the sensor data to detect any anomalies or signs of fluctuating oxygen levels.

As soon as a leak is detected, the system triggers instant notifications through various channels including, phone calls, email, SMS, and push notifications to the SoniCloud mobile app.

Can the alerts be customized?

We understand that every situation is unique, and your monitoring needs may differ from others.

That's why Sonicu's system allows you to customize alerts based on your specific requirements.

Whether you need alerts for specific areas, during certain time periods, or tailored to different stakeholders, our flexible alert system ensures you receive the right information at the right time.

Does Sonicu offer 24/7 monitoring and support?

Oxygen variances can occur at any time, day or night. That's why Sonicu provides round-the-clock monitoring and support, ensuring that you are protected at all times.

Our dedicated team of experts is available to assist you in monitoring, interpreting data, and providing guidance to mitigate the impact of fluctuating oxygen levels.

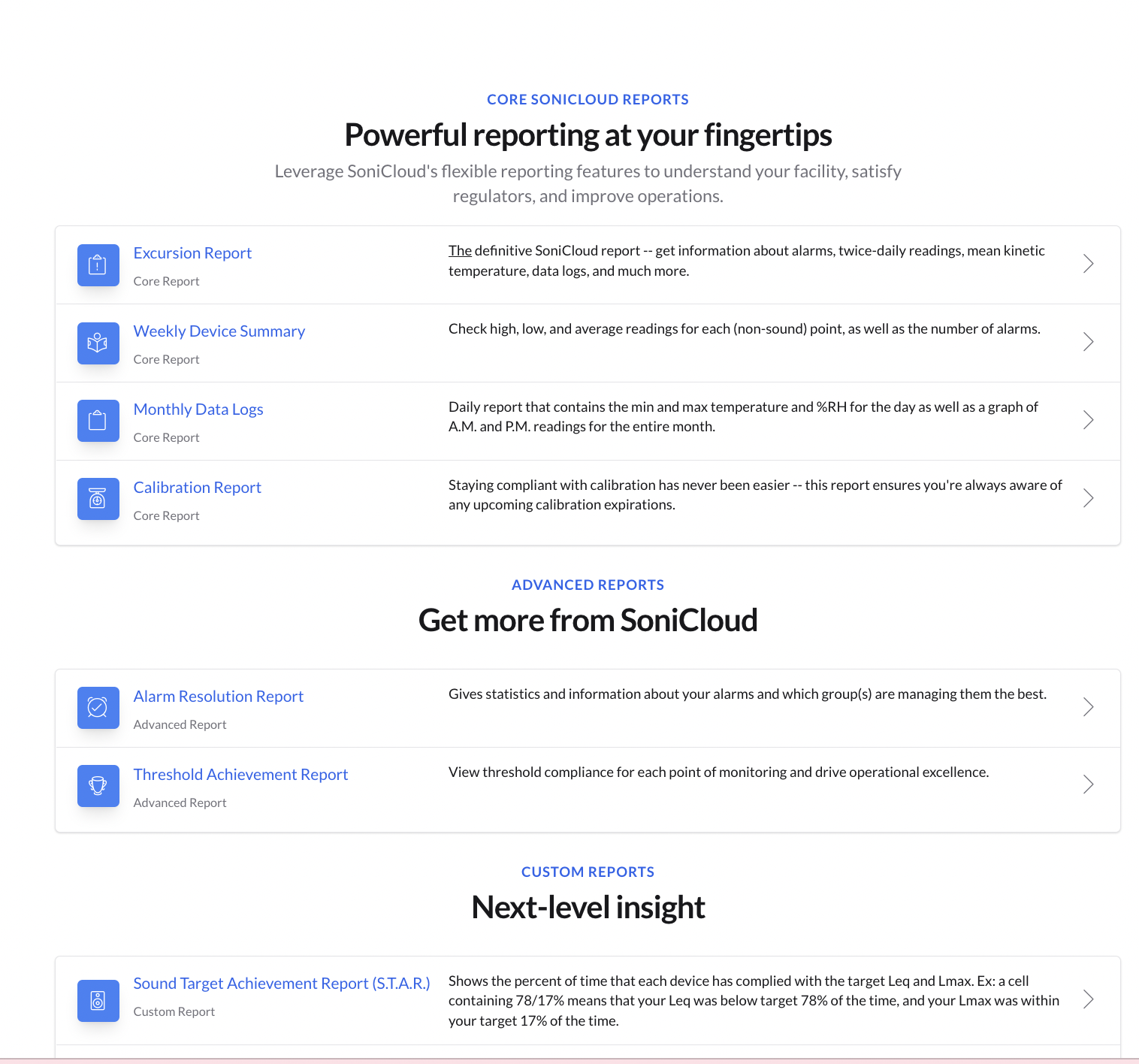

SoniCloud Platform

The dashboard provides aggregate views of all your monitored devices and offers many auto-generated reports including:

- Alarm History & Resolution

- Device Summary

- NIST Sensor Calibration

- Data Logs / Graphical Reports

- User Login Reports

Dashboard Access 24/7

- 24/7 monitoring, unlimited access, advanced alarms

- Dashboard views make it easy to manage all points of monitoring

- SMART Reporting tools auto-generate management and audit reports

The Sonicu Difference

Advanced Alarming

Cloud-based software capabilities with predictive algorithms for tailored alarming to reduce alarm fatigue and spot trends.

SMART Sensors

SMART sensors with proprietary DataSync capture. Preserve and secure data in the event of transmission interruptions.

SMART Reporting

Automated logging and reporting are unrivaled in the industry for effortless regulatory compliance.

Battery Backup

Industry-leading battery life on all sensors. In the event of a power outage, Sonicu's wireless sensors continue to keep you notified.

The Safest Network

Virtual Private Network (VPN) on Verizon's cellular platform will eliminate security concerns when transmitting data to the cloud.

Flexible Transmission

Replace server-based systems and eliminate IT concerns with a variety of transmission signals including: 4G/5G cellular, radio frequency, WiFi, and Ethernet.

Recalibration is Easy

All-digital temperature probes for easy calibration renewal with Sonicu's SNAP calibration program.

Ensuring Consistency

Service quality and connectivity reports provide a detailed analysis of system operations.

Request a Quote

O2 Sensors and O2 Monitoring 101: All You Need to Know

Oxygen sensors, also known as O2 sensors, are electronic devices used to measure the level of oxygen concentration in various gasses, such as the air we breathe. They play a crucial role in oxygen monitoring in different applications, and here's how they work and their connection to oxygen monitoring:

Oxygen sensors are typically small devices equipped with a sensing element made of materials like zirconia or electrochemical cells. These sensors respond to changes in the concentration of oxygen in their surroundings. The sensor generates an electrical signal that corresponds to the oxygen content in the gas being measured.

One of the most common uses of oxygen sensors is in the automotive industry, particularly in the exhaust system of internal combustion engines. In modern vehicles, oxygen sensors help monitor the amount of oxygen in the exhaust gasses. This enables the engine control unit (ECU) to adjust the air-fuel mixture to maintain an ideal ratio for efficient combustion and to reduce harmful emissions.

There are generally two types of oxygen sensors used in vehicles.

The heated oxygen (HO2S) sensor is located in the exhaust manifold or the exhaust pipe. It works at higher temperatures to provide more accurate readings. The ECU uses the sensor's data to adjust the fuel injection and optimize engine performance.

Alternatively, some modern vehicles use Air-Fuel Ratio (AFR) sensors, which are more advanced than traditional HO2S. AFR sensors provide more precise information about the air-fuel mixture, allowing the ECU to fine-tune the engine's operation even better.

Also, oxygen sensors are essential in medical equipment, like pulse oximeters, which measure the oxygen saturation level in a patient's blood. These sensors help monitor the respiratory status of patients and are crucial in various medical settings, especially during surgeries and in cases of respiratory diseases.

In environmental monitoring, oxygen sensors are also used to measure oxygen levels in bodies of water, like rivers and lakes. Monitoring the dissolved oxygen content is critical to assess water quality and its impact on aquatic life.

In industrial settings, oxygen sensors are utilized in processes that require precise control of oxygen levels. For instance, they are employed in controlled atmosphere environments for welding, metal fabrication, and heat treatment.

Lastly, aerospace applications utilize oxygen sensors in spacecraft and aircraft to ensure that cabin pressure remains safe and breathable for passengers and crew members.

Overall, oxygen sensors are vital components in various industries and applications, as they enable accurate and real-time monitoring of oxygen levels, leading to better control, efficiency, and safety in many processes and systems.

What are the key functions of O2 sensors across different industries and applications?

The key functions of oxygen sensors (O2 sensors) revolve around measuring and monitoring the concentration of oxygen in different environments. These functions are crucial for various industries and applications, as they enable precise control, optimization, and safety.

The primary function of an oxygen sensor is to measure the concentration of oxygen in gasses or liquids. This is achieved through the sensing element within the sensor, which reacts to changes in oxygen levels in its surroundings. The sensor generates an electrical signal proportional to the oxygen concentration, providing real-time data for monitoring purposes.

In the automotive industry, oxygen sensors play a critical role too in controlling the air-fuel ratio in the engine's combustion process. The sensor measures the oxygen content in the exhaust gasses, and the information is sent to the engine control unit (ECU). The ECU then adjusts the fuel injection to maintain an optimal air-fuel mixture for efficient combustion and reduced emissions.

Oxygen sensors are vital components in modern vehicles' emissions control systems. By ensuring the correct air-fuel ratio, the sensors help minimize harmful emissions of nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons (HC). This is crucial for meeting environmental regulations and reducing air pollution.

In medical applications, oxygen sensors are used to monitor the oxygen saturation level in a patient's blood. Pulse oximeters, equipped with oxygen sensors, provide non-invasive and real-time measurements. This allows healthcare professionals to assess a patient's respiratory status and intervene if necessary.

In environmental applications, oxygen sensors are used to measure dissolved oxygen levels in bodies of water, such as lakes, rivers, and oceans. This information is vital for assessing water quality, understanding aquatic ecosystems' health, and detecting potential pollution or oxygen depletion issues.

Oxygen sensors are also employed in various safety-critical applications, such as confined spaces, laboratories, and industrial settings, to monitor oxygen levels and ensure the safety of personnel. Low oxygen levels (oxygen deficiency) can be dangerous and even life-threatening, making oxygen sensors essential for detecting potential hazards.

In industrial processes that require precise oxygen control, such as welding, metal fabrication, and heat treatment, oxygen sensors help maintain the desired atmosphere to achieve optimal results. These sensors assist in preventing defects, ensuring material quality, and improving process efficiency.

In aerospace and aviation, oxygen sensors are utilized to monitor cabin pressure in aircraft and spacecraft. The sensors help detect any deviations in oxygen levels and contribute to maintaining a safe and breathable environment for passengers and crew at high altitudes.

O2 sensors are used in the food and beverage industry to monitor oxygen levels in packaging to extend product shelf life and preserve freshness.

O2 monitoring solutions also help industries comply with environmental regulations by providing accurate data on oxygen levels and emissions, leading to better environmental management and reduced ecological impact.

In scientific research and experimentation, O2 sensors are used to monitor and control oxygen levels in controlled environments like laboratories ensuring accurate and repeatable results.

Lastly, O2 monitoring is critical in chemical and petrochemical industries to prevent accidents and ensure the safe handling of gaseous and volatile substances.

Oxygen sensors play a critical role in various industries and applications by enabling accurate and continuous monitoring of oxygen levels. Their functions contribute to increased efficiency, safety, compliance, and improved environmental conditions.

Real-time O2 Level monitoring capabilities

Modern O2 sensors, especially those used in critical applications like automotive emissions control, medical monitoring, and safety systems, are designed to provide real-time measurements with rapid response times. These sensors use advanced technologies, such as zirconia or advanced electrochemical cells, to achieve faster response rates.

In automotive applications, for instance, real-time O2 sensors play a crucial role in providing continuous feedback to the engine control unit (ECU) to adjust the air-fuel mixture dynamically and optimize combustion efficiency. Similarly, in medical pulse oximeters, the oxygen sensors offer immediate readings, allowing healthcare professionals to monitor patients' oxygen saturation levels in real-time.

For safety monitoring in confined spaces or hazardous environments, real-time O2 sensors are vital to detect rapid changes in oxygen levels and provide timely warnings to ensure worker safety.

Advancements in sensor technology, signal processing, and data transmission have significantly improved the responsiveness and accuracy of O2 monitoring solutions. These real-time capabilities make O2 sensors even more valuable in critical applications where timely data is essential for decision-making and control.

Besides O2 sensors, what are the other key components of O2 monitoring solutions?

An oxygen (O2) monitoring solution typically involves multiple components to ensure accurate and reliable measurements of oxygen levels in various environments. Besides oxygen sensors (O2 sensors), some other key components of an O2 monitoring solution may include:

-

-

-

-

-

- A data logger or monitor is a device that collects and records the data from the oxygen sensors over time.

-

-

-

-

-

-

-

-

-

- It can display real-time oxygen levels and store historical data for analysis and trend monitoring.

-

-

-

-

-

-

-

-

-

- Data loggers can be standalone units or integrated into more extensive monitoring systems.

-

-

-

-

-

-

-

-

-

- To ensure the accuracy of oxygen sensors, regular calibration is necessary.

-

-

-

-

-

-

-

-

-

- Calibration gasses with known oxygen concentrations are used to calibrate the sensors periodically, making sure they provide reliable measurements.

-

-

-

-

-

-

-

-

-

- In some applications, a sample line is used to connect the oxygen sensor to the target environment for measurement.

-

-

-

-

-

-

-

-

-

- The sample line ensures that the gas being measured reaches the sensor and allows for remote placement of the sensor in hazardous or hard-to-reach locations.

-

-

-

-

-

-

-

-

-

- In more complex monitoring setups, a sampling system may be used to extract gas samples from different locations and bring them to the oxygen sensor(s) for analysis.

-

-

-

-

-

-

-

-

-

- The sampling system can include pumps, valves, and filters to manage gas flow and prepare the sample for measurement.

-

-

-

-

-

-

-

-

-

- Oxygen sensors require a power supply to operate.

-

-

-

-

-

-

-

-

-

- Depending on the type of sensor and application, this can be batteries, direct power from the equipment being monitored, or an external power source.

-

-

-

-

-

-

-

-

-

- For user-friendly operation and data visualization, an O2 monitoring solution may include a user interface, such as a graphical display or software interface, or mobile app.

-

-

-

-

-

-

-

-

-

- This interface allows users to view oxygen levels, set alarm thresholds, and access historical data.

-

-

-

-

-

-

-

-

-

- In critical applications, an O2 monitoring solution may include an alarm and alert system to notify users if oxygen levels deviate from the desired range.

-

-

-

-

-

-

-

-

-

- Audible and visual alarms can alert operators to potential hazards or abnormal conditions.

-

-

-

-

-

-

-

-

-

- In industrial and remote monitoring scenarios, communication interfaces such as Ethernet, Wi-Fi, Bluetooth, or other networking protocols enable data transmission to central control systems, databases, or cloud-based platforms.

-

-

-

-

-

-

-

-

-

- In more advanced applications, data analysis software may be used to process the collected data, generate reports, and analyze trends over time.

-

-

-

-

-

-

-

-

-

- This can provide valuable insights into system performance and help optimize processes.

-

-

-

-

-

-

-

-

-

- For outdoor or hazardous environments, oxygen monitoring solutions may include protective enclosures to shield the equipment from environmental factors and potential damage.

-

-

-

-

It's important to note that the specific components and complexity of an O2 monitoring solution will vary depending on the application, the level of precision required, and the environmental conditions in which the monitoring takes place. Some solutions may consist of simple handheld devices. While others may involve complex, integrated systems for continuous monitoring and control.

Sonicu’s wireless oxygen monitor offers advanced technology to track oxygen levels in real time, ensuring safety and compliance in a wide range of environments. With wireless monitoring solutions, you can remotely monitor oxygen levels across your facility, providing peace of mind that air quality is always at optimal levels.

For facilities that require wireless facility monitoring, we provide robust, scalable solutions that ensure real-time monitoring of vital environmental variables, including oxygen levels. Sonicu’s room oxygen sensor is an essential tool for accurately detecting and measuring oxygen levels within enclosed spaces. If the oxygen level falls below a safe threshold, the room oxygen monitor alarm will alert you immediately, preventing potential hazards.

Sonicu’s room oxygen monitor systems are designed for reliability and ease of use, providing constant monitoring of oxygen levels. For more advanced needs, the remote facility monitoring system allows you to access data from anywhere, providing flexibility and real-time alerts.

We offer real-time O2 measurement with high-performance systems, ensuring accurate tracking of oxygen levels across various environments. A portable O2 monitoring system offers the convenience of mobility, allowing users to measure oxygen levels in any location. Whether in industrial settings or healthcare facilities, Sonicu’s oxygen monitoring system is built to meet stringent safety standards.

The oxygen monitoring sensor is designed to deliver precise readings of oxygen levels, making it ideal for critical environments. For situations where every second counts, the oxygen monitor alarm and low oxygen alarm provide immediate notification of any oxygen deficiency. Sonicu’s oxygen level sensor helps you stay on top of changing conditions, minimizing risks associated with oxygen depletion.

With our oxygen depletion monitor, you can continuously track oxygen levels and receive alerts about potential oxygen depletion or O2 deficiency, ensuring that corrective actions can be taken before dangerous situations arise. The oxygen depletion alarm is an essential feature for high-risk environments, providing a critical safety measure for workers and occupants.

Oxygen control system allows for automated adjustments to maintain optimal oxygen levels in any given environment. For specialized applications, such as in the beverage industry, our oxygen beverage telemetry provides accurate tracking and control of oxygen levels in your production line.

With Sonicu’s O2 monitoring system, you can ensure continuous, uninterrupted monitoring of oxygen levels, supported by a reliable continuous oxygen monitor with an alarm system. Sonicu’s environmental oxygen monitor is perfect for monitoring the atmosphere in large spaces, ensuring safe oxygen concentrations for occupants.

For facilities that require cloud-based access, we offer cloud wireless monitoring solutions, enabling remote oversight and control of oxygen levels. Whether you're managing a large facility or a small operation, our atmosphere oxygen monitor provides the flexibility you need to track and maintain optimal oxygen levels in any environment.

Pros

-

-

-

-

-

- O2 sensors enable precise air-fuel ratio control in combustion processes, leading to reduced emissions of harmful pollutants, such as NOx, CO, and HC, in industries and automotive applications.

-

-

-

-

-

-

-

-

-

- O2 monitoring solutions help ensure the safety of workers in confined spaces and hazardous environments by detecting oxygen deficiencies and potential risks.

-

-

-

-

-

-

-

-

-

- O2 monitoring aids industries in complying with environmental regulations, allowing them to manage emissions and reduce their ecological impact effectively.

-

-

-

-

-

-

-

-

-

- In industrial processes, O2 sensors contribute to optimized combustion, leading to improved energy efficiency and reduced fuel consumption.

-

-

-

-

-

-

-

-

-

- O2 sensors in pulse oximeters provide vital data for medical professionals to monitor patients' oxygen levels non-invasively, aiding in diagnosis and treatment.

-

-

-

-

-

-

-

-

-

- O2 sensors are essential for monitoring dissolved oxygen levels in bodies of water, helping assess water quality and its impact on aquatic ecosystems.

-

-

-

-

-

-

-

-

-

- O2 monitoring ensures the maintenance of the desired atmosphere in various industrial processes, leading to improved product quality and reduced defects.

-

-

-

-

Cons

-

-

-

-

-

- O2 sensors may experience sensor drift over time, leading to deviations in readings. This drift requires timely recalibration or replacement.

-

-

-

-

The Power of O2 Sensors and Monitoring: Unraveling Advantages and Considerations

This was a journey of exploration into the world of O2 sensors and monitoring solutions. In this insightful voyage, we have uncovered the significance of these unassuming devices, as they silently address critical challenges across industries.

Amidst the complexities, O2 sensors emerge as stalwart companions, delivering numerous advantages to the fields they serve. From ensuring regulatory compliance and reducing emissions to safeguarding worker safety in hazardous environments, these sensors prove indispensable in industrial, environmental, and healthcare domains. Their ability to optimize combustion processes and monitor water quality contributes significantly to efficiency and ecosystem preservation.

As with any tool, O2 sensors come with their share of considerations. Regular calibration and maintenance are prerequisites to uphold accuracy and reliability. Vigilance against potential sensor drift and acknowledging environmental limitations reinforce the need for prudent decision-making.

Rest assured, the journey of O2 monitoring solutions has evolved significantly. Modern O2 sensors like Sonicu’s boast real-time capabilities, delivering instantaneous and precise data. With timely information at your disposal, you can respond swiftly to changes, optimize processes, and ensure safety in critical applications.

With newfound wisdom, charting a successful course in the O2 seas becomes attainable. Selecting cutting-edge O2 monitoring solutions tailored to your specific needs empowers you to overcome challenges and embrace opportunities. Let accuracy, efficiency, and effectiveness guide your way.

In the realm of O2 sensors and monitoring solutions, prudence and foresight prevail. Embrace the power of accurate data and its potential to transform your operations. As you venture forth, remember the key to success lies in choosing wisely and investing in solutions that resonate with your objectives.