Real-Time Data Access Temperature Monitoring

If you are looking for a real-time temperature monitoring system that helps you and your team eliminate manual logging, improve compliance readiness, and protect all your temperature-sensitive assets, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts via text, email, push notifications and phone calls to protect your precious assets

- Compliance: Automated compliance reports

- Efficiency: Reduced Manual Logging and time spent on reports

And what makes us different?

- Lifetime Warranty: Never buy hardware again!

- Unlimited Users: Scale across your entire organization

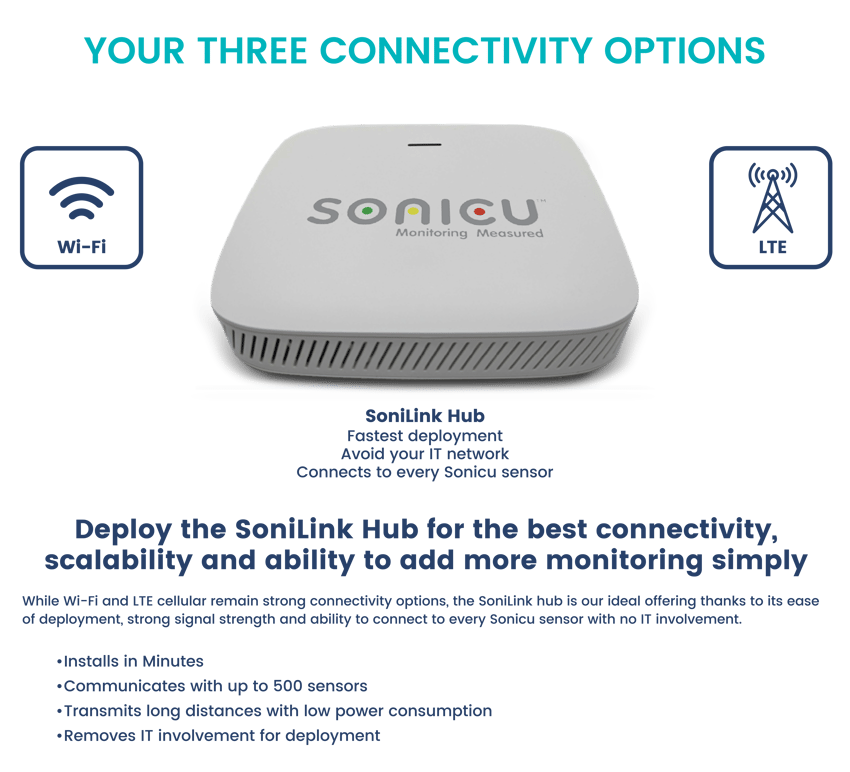

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

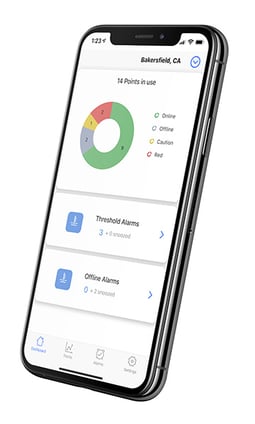

- Mobile App: 500 Freezers in your pocket

- Facility monitoring: Simple to add water leak, door open, occupancy, and even IAQ monitoring

Engineered in Indiana with U.S.-based support.

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

- Real-Time Monitoring: The sensors collect temperature data and transmit it wirelessly to Sonicloud - our cloud-based platform.

- Operational Efficiency: Virtually eliminate the need for tedious and costly manual logging

- Compliance Automation: Respond to virtually any regulatory audit or inspection in a few clicks with our reports section

- Asset Protection: Detect and respond to any temperature excursion that can threaten virtually anything perishable: food, drugs, vaccines, research, etc.

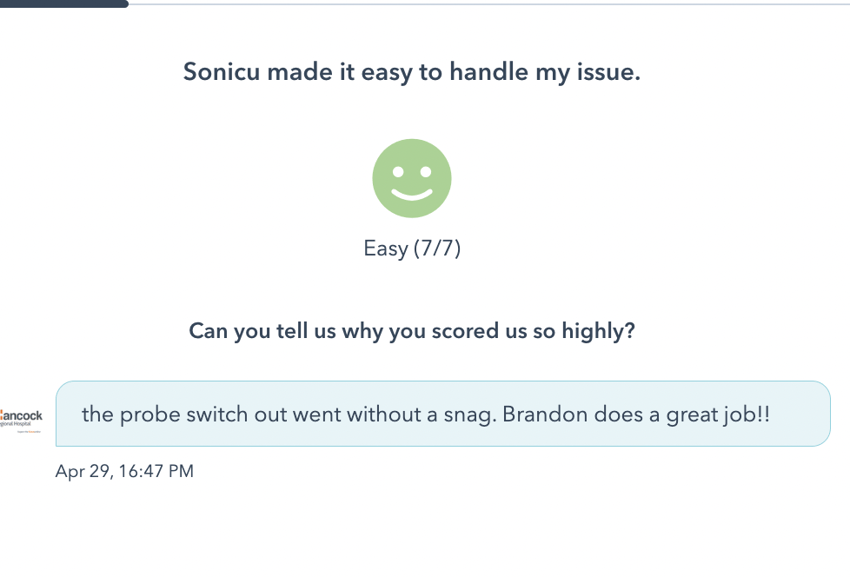

Our customers stay with us thanks to our American-based customer support, which is never more than a phone call away. While our technology is intuitive and powerful, we know it’s only as strong as the people who stand behind it.

Cost competitiveness, great customer service, great control over the monitoring system, and low maintenance. You can't beat that.

Sonicu costs are considerably more reasonable than our historic system, as well as other competitors on the market. The equipment is robust but simple to learn and utilize.

Having safe and secure storage provides reassurance that any future family building efforts will be protected. Sonicu gave us the ability to more easily put our head on the pillows and sleep easier at night knowing we had invested in a strong monitoring system.”

Revolutionizing Operations: How Real-Time Accessible Data Temperature Monitoring is Changing the Game

Real-time accessible data temperature monitoring refers to the continuous tracking and recording of temperature data in real-time. This technology allows for immediate observation and analysis of temperature conditions, which is crucial in various industries for maintaining quality, safety, and compliance standards.

Real-time temperature monitoring systems continuously collect and transmit temperature data, often through wireless sensors.

The collected data is typically accessible through cloud-based platforms, allowing users to view temperature readings from any location in real-time.

These systems often include features like alerts or notifications sent to relevant personnel when temperatures deviate from predefined ranges.

In healthcare and pharmaceuticals, real-time data access temperature monitoring ensures vaccines are stored at the correct temperatures to maintain their efficacy.

In laboratories, they help monitor temperature conditions for sensitive samples and reagents in research and clinical laboratories.

In cold chain management, they help maintain appropriate temperatures during the transportation and storage of perishable food products. These systems also ensure that food is stored and processed in conditions that prevent spoilage and contamination.

In data centers, they assist in tracking and managing the temperature to prevent overheating and damage of servers and other critical IT equipment.

In manufacturing, real-time data access temperature monitoring helps maintain optimal temperatures for various manufacturing processes, especially in chemical and materials industries.

They also help monitor the temperature conditions of goods like electronics, art, and other temperature-sensitive items during transit.

These systems ensure that products, especially perishables and pharmaceuticals, maintain their quality throughout the supply chain.

They help industries meet strict regulatory requirements, particularly in healthcare and food industries.

Real-time monitoring allows for quick responses to temperature deviations, reducing waste and improving operational efficiency.

The data collected can be used for analytics, leading to better decision-making and optimization of processes.

In the food and pharmaceutical industries, it directly impacts consumer safety by ensuring products are stored and transported under safe conditions.

Real-time data access temperature monitoring plays a pivotal role in various industries, ensuring product quality, regulatory compliance, operational efficiency, and consumer safety. The technology has become increasingly sophisticated, with advanced analytics and IoT integration, further enhancing its impact on industry operations.

Founded in 2008 in Greenfield, Indiana, Sonicu began manufacturing noise monitors to protect vulnerable infants in neonatal intensive care units, and has evolved to monitor and protect a diverse set of sensitive conditions and environments.

What are the components of a real-time accessible data temperature monitoring system?

Real-time accessible data temperature monitoring systems are composed of several key components that work together to provide accurate and timely temperature data. These systems leverage a range of technologies to perform their functions effectively.

- Sensors

- Measure the actual temperature of the environment or object.

- Typically thermocouples, resistance temperature detectors (RTDs), or thermistors. They convert physical temperature into an electrical signal that can be measured.

- Data loggers or transmitters

- Collect data from the sensors and transmit it to a central system.

- They often use wireless technology (like Wi-Fi, Bluetooth, Zigbee) or wired connections for data transmission.

- Gateways and network connectivity

- Act as a bridge between the sensors/transmitters and the cloud or central monitoring system.

- Utilize cellular networks, Wi-Fi, or Ethernet to transmit data.

- Some systems use Low Power Wide Area Network (LPWAN) technologies like LoRaWAN for long-range, low-power communication.

- Cloud-based data storage

- Store the received temperature data securely and reliably.

- Cloud computing platforms are used for scalable, accessible, and secure data storage.

- Data analytics and processing software

- Analyze the collected data to derive insights, trends, and detect anomalies.

- Advanced data analytics, machine learning algorithms, and AI are often employed to process and interpret data.

- User interface (UI)

- Provide an accessible platform for users to monitor temperature data and receive alerts.

- Web-based dashboards or mobile applications that allow users to view real-time data, historical trends, and receive notifications.

- Alerts and notification system

- Notify stakeholders of temperature deviations or potential issues.

- Integrated with the UI, these systems use SMS, email, or in-app notifications to alert users.

- Power supply and backup

- Ensure continuous operation, especially in the case of power failures.

- Batteries, often rechargeable, and sometimes solar-powered options for remote or environmentally-friendly setups.

- Calibration and maintenance tools

- Regular calibration ensures accuracy and reliability.

- Software and hardware tools specific to the sensors and system for periodic checks and calibration.

- Internet of Things (IoT)

- Central to connecting various components, facilitating data exchange, and enabling remote monitoring.

- Machine learning and AI

- For predictive analytics and anomaly detection.

The combination of these components and technologies allows real-time accessible data temperature monitoring systems to function efficiently, providing accurate and timely data crucial for decision-making in various industries. The system's design can vary based on the specific requirements of the application, such as the range of temperatures to be monitored, the environment's nature, and the level of precision required.

Easy to install and configure and supported by live American-based phone support, Sonicu is the most affordable, intuitive, and trusted temperature and environmental monitoring solution nationwide.

You can learn more about how our software helps compliance professionals in these case studies:

Problem: Pharmacy Suffered Too Much Humidity In New Wing, impacting Compounding Pharmacy

Solution: Affordable Humidity Monitoring that Delivered Powerful data to prompt contractors to fix improperly sized air handler

Problem: Dining department struck with regulatory violations

Solution: Enterprise-wide monitoring that automates regulatory compliance across all departments

Problem: Release of lead particles in battery projects

Solution: Mobile, affordable air pressure monitoring solution

What are the pain points that a real-time accessible data temperature monitoring system can effectively address?

Real-time data access temperature monitoring systems are designed to tackle several stubborn pain points that are prevalent in industries where temperature control is critical. These systems effectively address issues related to safety, compliance, efficiency, and risk management.

Products, especially perishables and pharmaceuticals, can be ruined by even slight deviations in temperature. Real-time monitoring ensures immediate detection and response to any unwanted temperature changes, reducing spoilage and waste.

Many industries have strict regulatory requirements for temperature control (e.g., FDA regulations for food and pharmaceuticals). Continuous monitoring and accurate record-keeping aid in meeting these regulatory standards, ensuring compliance and avoiding legal issues.

Manual temperature monitoring is time-consuming, prone to human error, and not feasible for continuous tracking. Automated systems provide continuous, accurate monitoring without the need for constant manual intervention.

Overuse of cooling or heating resources due to lack of precise temperature control can lead to inefficiencies. Precise temperature monitoring allows for more efficient use of resources, reducing energy costs and environmental impact.

Temperature-sensitive products are at risk during transportation, especially over long distances or in varying climates. Real-time monitoring during transit ensures that any temperature deviations are promptly detected and addressed.

Difficulty with accessing historical temperature data for analysis and decision-making can lead to poorly informed strategies. Cloud-based storage of temperature data allows for easy access and analysis, facilitating informed decision-making.

Equipment failure can lead to temperature deviations. Monitoring systems can identify patterns indicating equipment malfunction, allowing for proactive maintenance before a failure occurs.

In environments like laboratories or manufacturing plants, improper temperature control can pose safety risks. Continuous monitoring ensures a safe environment by maintaining temperatures within safe limits.

Lack of visibility into the temperature conditions throughout the supply chain can lead to a lack of visibility. Real-time monitoring provides transparency and traceability, enhancing trust and reliability in the supply chain.

Delayed response to temperature excursions can result in significant losses. Instant alerts and notifications enable swift action to mitigate risks.

By addressing these pain points, real-time accessible data temperature monitoring systems significantly enhance operational efficiency, product quality, safety, and compliance across various industries. They also contribute to cost savings by reducing waste and improving resource utilization.

Asset Protection. Compliance Automation. And Reduced Manual Processes. Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

You can learn more about how our software helps compliance professionals in these case studies:

Problem: Too many false alarms on cryo monitoring lead to ignoring an alarm

Solution: Smart alarms that don’t produce alert fatigue

Problem: Cumbersome and costly legacy monitoring with difficult customer service

Solution: Simple and affordable solution with third-party sensor capabilities to drive down costs

Hamilton County Health Department: Vaccine Protection and Compliance.

Problem: Data loggers that lacked remote viewing capabilities and compliance automation

Solution: Remote viewing capabilities for weekend peace of mind and simple compliance

Key benefits of real-time accessible data temperature monitoring

- Ensures products, especially perishables and pharmaceuticals, are stored and transported under optimal conditions, maintaining their quality and safety.

- Helps meet stringent regulatory requirements, crucial in industries like healthcare, food, and pharmaceuticals.

- Automates the monitoring process, reducing the need for manual checks and thereby saving time and labor costs.

- Early detection of temperature deviations allows for quick corrective actions, reducing the risk of product spoilage or damage.

- Provides a wealth of data for analysis, leading to more informed decision-making and process optimization.

- Precise temperature control can lead to more efficient use of heating and cooling resources, reducing energy costs.

- Offers visibility into the conditions of products throughout the supply chain, enhancing accountability and trust.

- Immediate notifications of any issues allow for swift responses, minimizing potential losses.

- The accumulation of data over time can be valuable for trend analysis and predictive maintenance.

Embrace the Future with Sonicu: Mastering Temperature Monitoring for Operational Excellence

In the intricate tapestry of modern operations across diverse industries, the thread that often remains unseen yet critically vital is the precise monitoring of temperature. From safeguarding the integrity of pharmaceuticals to ensuring the freshness of farm-to-table produce, the role of real-time data access temperature monitoring systems cannot be overstated. As we have explored, these systems are not just tools; they are guardians of quality, compliance, and efficiency.

Sonicu stands at the forefront of this technological revolution, offering a range of cutting-edge real-time data access temperature monitoring solutions. Our systems are designed not just to meet the current demands of your operations but to propel them into a future of unparalleled efficiency and reliability. With Sonicu, you're not just installing a monitoring system, you're investing in peace of mind, knowing that your products, processes, and reputations are safeguarded against the unpredictable nature of temperature fluctuations.

As you stand at the crossroads of decision, remember that the path to enhanced operational integrity, compliance, and cost efficiency is illuminated by the advanced solutions offered by Sonicu. The future is not just about monitoring temperature, it's about mastering it.

Take the Leap with Sonicu

Are you ready to elevate your operations to the next level? Embrace the future with Sonicu's range of real-time data access temperature monitoring solutions. Visit our website, explore our products, and let us help you transform your temperature monitoring challenges into triumphs. Your journey toward operational excellence begins with Sonicu.

American-based Customer Support: Robust & Reliable High Touch Service

Software and technology is only as good as the people who stand behind it.

At Sonicu, that means our team of American-based customer success managers who are never more than a phone call away to help field and fix any service issues.

Our probes and sensors are placed in demanding frozen environments and our software literally sends billions bits of data monthly, meaning there’s always the potential for a hiccup on either the hardware or software.

We are committed to fielding every customer service request promptly and addressing our customer’s concerns promptly and professionally.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

Before Sonicu, we had to don bunny suits to check the status of our cleanrooms. Now we check our phones and know right away. The system saves us time and effort and helps us respond to environmental