Remote Air Pressure Monitoring

If you are looking for a remote air pressure monitoring system that helps you and your team eliminate manual logging, improve compliance readiness, and protect all your temperature-sensitive assets, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts to protect assets

- Compliance: Automated reports

- Efficiency: Reduced Manual Logging

And what makes us different?

- Lifetime Warranty: Never buy hardware again!

- Unlimited Users: Scale across your entire org

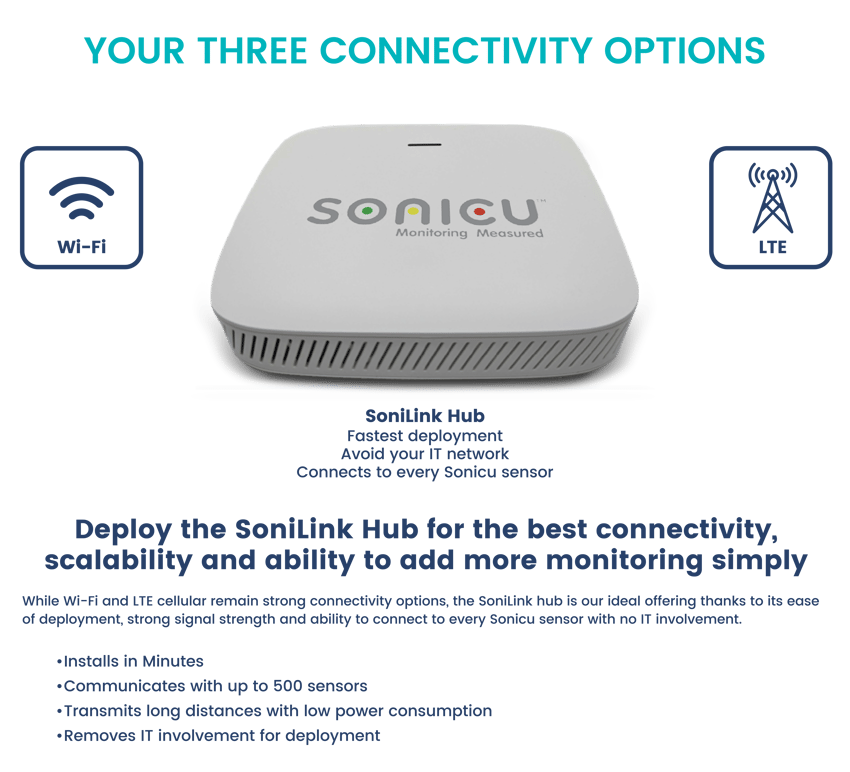

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

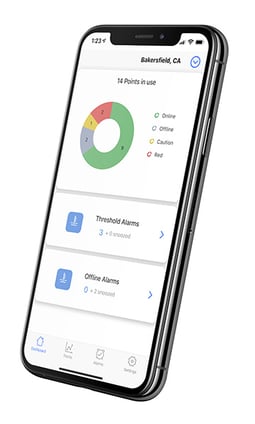

- Mobile App: 500 Freezers in your pocket

All American made and supported!

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

Remote Air Pressure Monitoring

Some of the finest names in healthcare, including Indiana University Health, University of Michigan Health System, and Stanford University rely on Sonicu to provide a robust and continuous environmental monitoring system, including temperature, humidity, air pressure, and more.

These respected healthcare and research brands turn to Sonicu for four primary reasons:

- Real-Time Monitoring: the sensors collect temperature, humidity, air pressure data, and more, and transmit it wirelessly to SoniCloud - our cloud-based platform.

- Operational Efficiency: Virtually eliminate the need for tedious and costly manual logging

- Compliance Automation: Respond to any regulatory audit or inspection in a few clicks with our reports section

- Asset Protection: Detect and respond to any threshold that can threaten anything perishable: food, drugs, vaccines, research, etc.

Our customers stay with us thanks to our American-based customer support, which is never more than a phone call away. While our technology is intuitive and powerful, we know it’s only as strong as the people who stand behind it.

In today’s rapidly evolving technological landscape, industries are increasingly relying on remote monitoring systems to ensure operational efficiency, safety, and compliance.

Among these, remote air pressure monitoring has become a crucial component in various sectors, ranging from pharmacies and healthcare to food storage and data centers.

This article will delve into the intricacies of remote air pressure monitoring, highlighting its benefits, applications, and the cutting-edge technologies driving its adoption.

What is Remote Air Pressure Monitoring?

Remote air pressure monitoring involves the use of advanced sensors and communication technologies to track air pressure levels in real-time, without the need for manual inspections.

These systems collect data continuously and transmit it to centralized platforms, where it can be accessed and analyzed remotely.

This technology is essential for maintaining optimal conditions in controlled environments, ensuring equipment operates within safe parameters, and preventing costly downtime or failures.

Key Benefits of Remote Air Pressure Monitoring

Remote air pressure monitoring offers numerous advantages that make it an indispensable tool in various industries.

Real-Time Data and Alerts

One of the primary benefits of remote air pressure monitoring is the ability to receive real-time data and alerts.

Sensors constantly measure air pressure levels and transmit this information to a central system.

If the pressure deviates from the established thresholds, alerts are immediately sent to relevant personnel via text messages, emails, or mobile apps.

This real-time monitoring allows for swift corrective actions, minimizing the risk of damage to equipment or processes.

Enhanced Operational Efficiency

Remote air pressure systems significantly enhance operational efficiency by automating the monitoring process.

Manual checks are time-consuming and prone to human error, but with remote monitoring, air pressure data is continuously collected and analyzed without the need for on-site personnel.

This automation frees up staff to focus on other critical tasks, while also ensuring that air pressure is maintained within optimal ranges at all times.

Preventive Maintenance and Reduced Downtime

Remote air pressure monitoring plays a crucial role in preventive maintenance.

By tracking air pressure trends over time, the system can identify potential issues before they lead to equipment failure.

For example, a gradual drop in air pressure in a pneumatic system may indicate a leak or blockage that needs to be addressed.

Early detection allows maintenance teams to intervene before a minor issue escalates into a major problem, reducing downtime and associated costs.

Cost Savings

Implementing remote air pressure monitoring can lead to significant cost savings.

By preventing equipment failures and minimizing downtime, companies can avoid the high costs associated with emergency repairs and production halts.

Additionally, remote monitoring systems can optimize energy usage by ensuring that air pressure is maintained at the ideal level, reducing energy consumption and lowering utility bills.

Improved Safety and Compliance

In many industries, maintaining the correct air pressure is essential for safety and regulatory compliance.

For instance, in laboratories and cleanrooms, specific air pressure levels are necessary to prevent contamination.

In healthcare settings, precise air pressure control is critical in environments such as operating rooms and isolation wards.

Remote monitoring ensures that these environments remain safe and compliant with industry standards, reducing the risk of accidents and regulatory penalties.

Data Analytics and Reporting

Remote air pressure monitoring systems often come equipped with data analytics tools that provide valuable insights into system performance.

Historical data can be analyzed to identify trends, optimize processes, and make informed decisions.

Additionally, automated reporting features make it easy to generate compliance reports, maintenance logs, and performance summaries, saving time and ensuring accuracy.

Applications of Remote Air Pressure Monitoring

Remote air pressure monitoring has a wide range of applications across various industries. Here are some of the key sectors where this technology is making a significant impact.

Heating, ventilation, and air conditioning (HVAC) systems rely on precise air pressure control to maintain indoor air quality and comfort.

Remote air pressure monitoring ensures that HVAC systems operate efficiently, preventing issues such as poor air circulation, energy waste, and equipment failure.

By monitoring air pressure in real-time, building managers can ensure optimal performance and reduce maintenance costs.

Manufacturing and Industrial Processes

In manufacturing, maintaining the correct air pressure is critical for the operation of pneumatic tools, conveyor systems, and other equipment.

Remote monitoring helps detect leaks, blockages, and other issues that can affect production quality and efficiency.

Additionally, in industries such as pharmaceuticals and food processing, remote air pressure monitoring ensures that controlled environments remain within the required parameters to prevent contamination and ensure product safety.

Healthcare Facilities

In healthcare, remote air pressure monitoring is critical to maintaining sterile environments.

Operating rooms, isolation wards, and laboratories require specific air pressure levels to prevent the spread of airborne contaminants and infections.

Remote monitoring ensures that these environments remain safe for patients and healthcare workers, while also meeting stringent regulatory requirements.

Cleanrooms and Laboratories

Cleanrooms and laboratories require strict air pressure control to maintain a contaminant-free environment.

Remote air pressure monitoring ensures that these facilities adhere to industry standards, such as ISO 14644-1 for cleanroom classification. By continuously monitoring air pressure, facility managers can prevent contamination, ensure product integrity, and maintain compliance with regulatory requirements.

Transportation and Logistics

In the transportation and logistics sector, maintaining proper air pressure in cargo holds, storage containers, and shipping vessels is essential for preserving the quality of transported goods. Remote air pressure monitoring helps logistics companies track environmental conditions in real time, ensuring that perishable goods, chemicals, and other sensitive products are transported under optimal conditions.

Technologies Driving Remote Air Pressure Monitoring

The effectiveness of remote air pressure monitoring relies on a combination of advanced technologies that enable accurate data collection, transmission, and analysis.

Here are some of the key technologies that are driving the adoption of remote air pressure monitoring:

IoT (Internet of Things) Sensors

IoT sensors are at the heart of remote air pressure monitoring systems.

These sensors, like those offered by Sonicu, are designed to measure air pressure with high accuracy and reliability.

They are often equipped with wireless communication capabilities, allowing them to transmit data to centralized platforms in real time.

IoT sensors are available in various configurations to suit different applications, from industrial environments to cleanrooms and healthcare facilities.

Wireless Communication Protocols

Wireless communication is a critical component of remote air pressure monitoring.

Technologies such as Wi-Fi, Bluetooth, Zigbee, and LoRaWAN enable sensors to transmit data over long distances without the need for physical connections.

The choice of communication protocol depends on the specific requirements of the application, such as range, data rate, and power consumption.

For example, LoRaWAN is ideal for long-range, low-power applications, while Wi-Fi is suitable for high-data-rate environments.

Cloud-Based Platforms

Cloud-based platforms play a central role in remote air pressure monitoring by providing a centralized location for data storage, analysis, and access.

These platforms offer real-time dashboards, data analytics tools, and automated reporting features, allowing users to monitor air pressure from anywhere with an internet connection.

Cloud-based platforms also facilitate data sharing and collaboration, making it easier for teams to work together to ensure system performance and safety.

SoniCloud from Sonicu is a cloud-based platform tool that uses graphs, charts, and other user interface components so you can track and interact with different devices within your ecosystem.

The data in SoniCloud can be presented in a dashboard and can be used to organize, present, and manage data from numerous connected devices in your network.

Data Analytics and Machine Learning

Data analytics and machine learning technologies are increasingly being integrated into remote air pressure monitoring systems.

These technologies analyze historical and real-time data to identify trends, predict potential issues, and optimize system performance.

For example, machine learning algorithms can detect subtle changes in air pressure that may indicate a developing problem, allowing maintenance teams to intervene before it leads to equipment failure.

Mobile Apps and Remote Access

Mobile apps and remote access capabilities provide users with the flexibility to monitor air pressure from any location.

Whether on-site or off-site, users can access real-time data, receive alerts, and make adjustments through their smartphones or tablets.

This level of accessibility is particularly valuable for industries with multiple facilities or geographically dispersed operations.

Integration with Other Monitoring Systems

Remote air pressure monitoring systems are often integrated with other monitoring systems, such as temperature, humidity, and airflow monitoring.

This integration provides a comprehensive view of environmental conditions, allowing for more effective management of controlled environments.

For example, in a cleanroom, monitoring air pressure, temperature, and humidity together ensures that all factors are within the required ranges to prevent contamination.

Implementing Remote Air Pressure Monitoring: Best Practices

To maximize the benefits of remote air pressure monitoring, it is important to follow best practices during implementation.

Conduct a Needs Assessment

Before implementing a remote air pressure monitoring system, conduct a thorough needs assessment to understand the specific requirements of your operation.

Consider factors such as the environment in which the system will be used, the critical air pressure thresholds, and the desired level of automation and remote access.

Choose the Right Sensors

Selecting the right sensors is critical for the success of your remote air pressure monitoring system.

Ensure that the sensors you choose are suitable for the environment in which they will be used and that they meet the required accuracy and reliability standards.

Consider factors such as the sensor’s range, communication capabilities, and power requirements.

Integrate with Existing Systems

If you already have monitoring systems in place, consider integrating your remote air pressure monitoring system with these existing systems.

Integration allows for more comprehensive environmental monitoring and simplifies data management by consolidating information on a single platform.

Train Personnel

Proper training is essential for the effective use of remote air pressure monitoring systems.

Ensure that all relevant personnel are trained on how to use the system, interpret data, and respond to alerts.

Training should also cover routine maintenance and troubleshooting procedures to ensure the system remains operational.

Regularly Review and Optimize

Remote air pressure monitoring systems should be regularly reviewed and optimized to ensure they continue to meet the needs of your operation.

Regularly review system performance, analyze data trends, and adjust thresholds as needed. Periodic audits and maintenance checks should also be conducted to ensure the system remains accurate and reliable.

There are specific industries that are known to control the climate conditions of their working areas as they conduct business.

These industries can include, but are not limited to:

- Healthcare (hospitals and clinics),

- Pharmacies and pharmaceutical manufacturers,

- Food storage and distribution

- Vivariums

- Data centers

Controlling climate conditions may be required by law or simply done as a means of best practice.

Medications often have to be kept in climate-controlled rooms, and food items need to be in climate-controlled rooms so that they stay fresh.

Many environmental factors need to be considered, such as temperature and humidity.

What does air pressure actually mean and entail?

To define it briefly, air pressure (otherwise known as atmospheric pressure) is the force of a certain measured area on the Earth’s surface applied by the weight of the air above the surface.

Air pressure is measured by the number of molecules in any given area. The more molecules, the higher the air pressure becomes.

Likewise, air pressure decreases when the number of molecules goes down.

How is this relevant to hospitals and pharmacies?

Air pressure, if not properly controlled via an air pressure monitoring system, can result in the contamination of materials or the transmission of airborne diseases.

The locations where a hospital would place a pressure monitor include:

- Operating rooms

- Pharmacy compounding areas

- Intensive care units

- Delivery rooms

- Laboratories

- ER waiting rooms

Areas can be either positively or negatively pressurized, depending on the purpose of the area.

A room is pressurized positively to keep the space clean and keep as many pathogens from the outside from coming in as possible.

A room is negatively pressurized to keep pathogens within the space from escaping to the outside.

For example, COVID patients would have been placed in negatively pressurized intensive care units because the risk of COVID patients contaminating the outside area was a greater risk than anything that could have come into the space from outside areas.

Sonicu offers comprehensive solutions for remote air pressure monitoring that are designed to meet the needs of various industries, including healthcare, laboratories, cleanrooms, and manufacturing.

These solutions provide real-time monitoring, data logging, and alerting capabilities to ensure that air pressure levels remain within critical thresholds.

Here’s an overview of what Sonicu offers:

1. Wireless Air Pressure Sensors

Sonicu provides advanced wireless air pressure sensors that can monitor differential pressure in various environments.

These sensors are designed to accurately measure and transmit data on air pressure levels, allowing users to maintain the appropriate pressure differentials necessary for cleanrooms, isolation rooms, and other controlled environments.

2. Real-Time Monitoring and Alerts

Sonicu’s remote air pressure monitoring solutions include real-time monitoring capabilities.

The sensors continuously collect data on air pressure and transmit it to a central platform. If the air pressure deviates from the set thresholds, the system automatically sends alerts via text, email, or app notifications to designated personnel.

This ensures that any issues are promptly addressed before they can impact operations.

3. Cloud-Based Monitoring Platform

Sonicu’s solutions are supported by a cloud-based monitoring platform, SoniCloud, that provides users with real-time access to data from anywhere with an internet connection.

This platform features customizable dashboards, where users can view air pressure data, set alert thresholds, and generate reports.

The cloud platform also offers data redundancy and security, ensuring that data is always available and protected.

4. Data Logging and Reporting

The Sonicu system includes robust data-logging capabilities that automatically record air pressure readings over time.

This historical data can be easily accessed for analysis, audits, and compliance reporting.

The platform supports automated reporting, enabling users to generate detailed reports for regulatory compliance, quality assurance, and performance optimization.

5. Seamless Integration with Other Monitoring Systems

Sonicu’s air pressure monitoring solutions can be integrated with other environmental monitoring systems, such as temperature, humidity, and air quality monitoring.

This integration provides a comprehensive view of the environmental conditions within a facility, allowing for more effective management of controlled environments.

6. Scalable and Flexible Solutions

Sonicu’s remote air pressure monitoring solutions are scalable and can be tailored to meet the specific needs of different facilities. Whether monitoring a single room or an entire facility,

Sonicu’s system can be expanded to include additional sensors and monitoring points as needed.

7. Compliance and Audit Support

Sonicu’s monitoring solutions are designed to help organizations maintain compliance with industry standards and regulations, such as those set by the FDA, CDC, and ISO.

The system’s automated reporting and data logging capabilities make it easier to prepare for audits and ensure that all regulatory requirements are met.

8. User-Friendly Interface and Support

Sonicu’s platform is designed with a user-friendly interface that simplifies the process of monitoring, managing alerts, and generating reports.

Additionally, Sonicu offers customer support and training to ensure that users can fully leverage the system’s capabilities and maintain optimal air pressure conditions.

In summary, Sonicu offers a comprehensive suite of remote air pressure monitoring solutions that provide real-time data, automated alerts, robust data logging, and seamless integration with other environmental monitoring systems.

These solutions are designed to enhance operational efficiency, ensure compliance, and protect the integrity of controlled environments in various industries.

You can learn more about how Sonicu software helps compliance professionals in these case studies:

Cryopoint: Mission-Critical Monitoring

Problem: Cryopoint faced calibration challenges with their legacy monitoring system and issues with a server-based system, putting critical samples at risk.

Solution: Transitioned to Sonicu's SoniCloud and its mobile-first solution, enhancing reliability in monitoring and easing operations.

Ohio University Innovation Center

Problem: Tech and tech-enabled startups at the Innovation Center needed reliable support systems for temperature and environmental monitoring due to the requirements of grant-funded projects.

Solution: They implemented Sonicu for comprehensive monitoring of temperature, ambient humidity, and air pressure differential, ensuring necessary protection and compliance.

Hancock Regional Health: Enterprise Monitoring from Sound to Environmental

Problem: Disparate monitoring systems were taxing the staff with many manual processes, leading to inefficiencies and reduced asset protection.

Solution: CEO Steve Long initiated the adoption of a consolidated monitoring program for temperature, environmental, and sound, which automated compliance and reduced manual logging.

If you’re looking for a cloud-based hospital remote air pressure monitoring system that helps your team eliminate manual logging, improve compliance readiness, and protect all your sensitive assets, Sonicu has you covered.

Conclusion

Remote air pressure monitoring is a powerful tool that offers numerous benefits across various industries.

By providing real-time data, enhancing operational efficiency, reducing downtime, and ensuring compliance, these systems play a crucial role in maintaining safe and efficient operations.

The integration of advanced technologies, such as IoT sensors, wireless communication, and cloud-based platforms, further enhances the capabilities of remote air pressure monitoring, making it an essential component of modern industrial and environmental management.

As industries continue to embrace digital transformation, the adoption of remote air pressure monitoring systems is expected to grow.

By following best practices and leveraging the latest technologies, organizations can ensure that they remain at the forefront of operational excellence and safety.

American-based Customer Support: Robust & Reliable High Touch Service

Software and technology is only as good as the people who stand behind it.

At Sonicu, that means our team of American-based customer success managers who are never more than a phone call away to help field and fix any service issues.

Our probes and sensors are placed in demanding frozen environments and our software literally sends billions bits of data monthly, meaning there’s always the potential for a hiccup on either the hardware or software.

We are committed to fielding every customer service request promptly and addressing our customer’s concerns promptly and professionally.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

How IU Health

consolidated all of its pharmacy monitoring needs

into one cloud-based platform serving dozen of locations.