SoniLink Hub

Plug and play connectivity for hundreds of meters with just one access point.

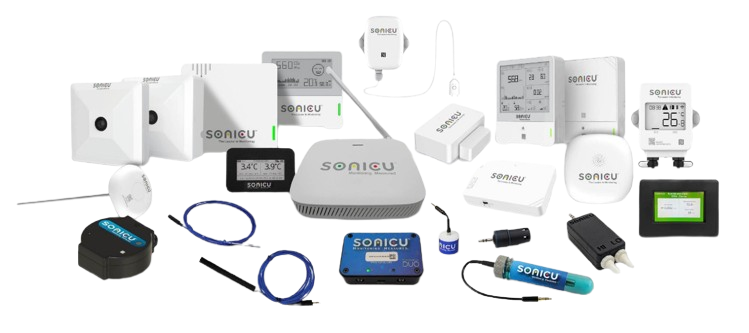

Sonicu offers a comprehensive suite of monitoring solutions

that help organizations safeguard assets, automate compliance and reduce manual processes.

From protecting vaccines and research materials to safeguarding food service and facility operations, Sonicu’s monitoring applications cover temperature, humidity, pressure, and more. Whether you’re in healthcare, life sciences, food safety, or other industries, Sonicu provides visibility, compliance, and peace of mind across all your critical applications.

Designed with safety, efficiency and compliance always top of mind, we’ve evolved over a decade with continuous improvements from customer feedback. Serving the healthcare, research and food service industries.

Whether you're solving basic temperature monitoring needs or managing complex, multi-environment compliance, Sonicu’s full line of meters, sensors, and hubs has you covered.

Sonicu offers a comprehensive suite of monitoring solutions

that help organizations safeguard assets, automate compliance and reduce manual processes.

Understanding Heat Stress and OSHA Regulations: How to Protect Your Employees and Ensure Compliance

From simple to sophisticated: monitoring hardware that adapts to your needs.

Whether you're solving basic temperature monitoring needs or managing complex, multi-environment compliance, Sonicu’s full line of meters, sensors, and hubs has you covered.