Ultra Low Freezer Temperature Monitor

If you’re looking for an ultra low freezer temperature monitor that eliminates manual logging, improves compliance readiness and protects all your clean rooms and compounding rooms, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts to protect assets

- Compliance: Automated reports

- Efficiency: Reduced Manual Logging

And what makes us different?

- Lifetime Warranty: Never buy hardware again!

- Unlimited Users: Scale across your entire org

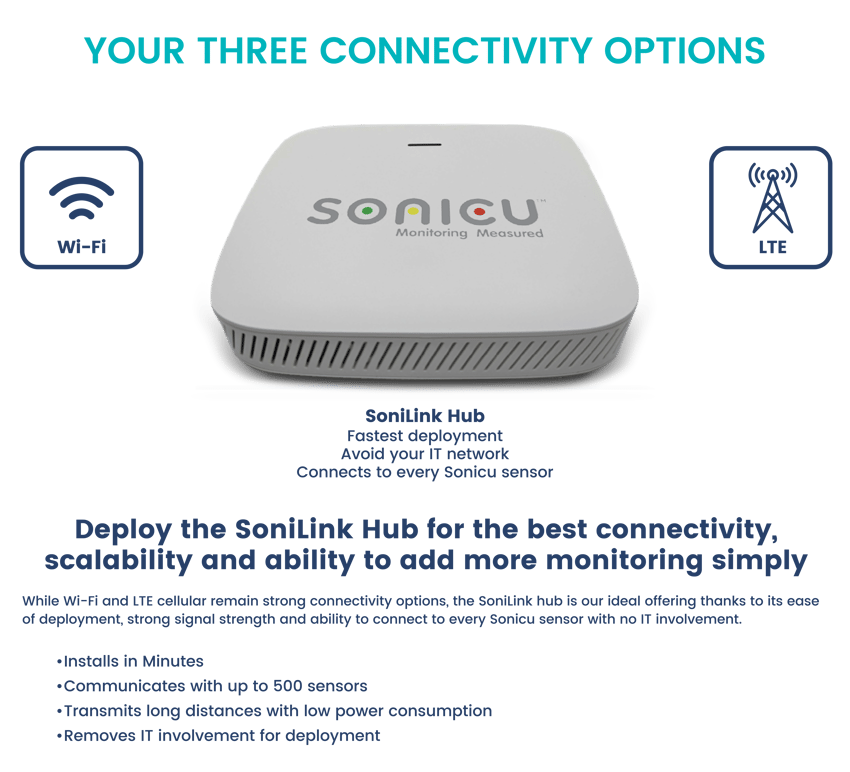

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

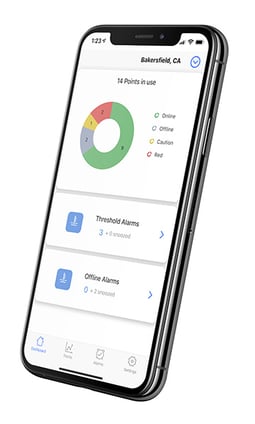

- Mobile App: 500 Freezers in your pocket

All American made and supported!

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

Ultra Low Freezer Temperature Monitor

Some of the finest names in healthcare, including Indiana University Health, University of Michigan Health System, and Stanford University rely on Sonicu to provide a robust and continuous environmental monitoring system, including temperature, humidity, air pressure, and more.

These respected healthcare and research brands turn to Sonicu for four primary reasons:

- Real-Time Monitoring: the sensors collect temperature, humidity, air pressure data, and more, and transmit it wirelessly to SoniCloud - our cloud-based platform.

- Operational Efficiency: Virtually eliminate the need for tedious and costly manual logging

- Compliance Automation: Respond to any regulatory audit or inspection in a few clicks with our reports section

- Asset Protection: Detect and respond to any threshold that can threaten anything perishable: food, drugs, vaccines, research, etc.

Our customers stay with us thanks to our American-based customer support, which is never more than a phone call away. While our technology is intuitive and powerful, we know it’s only as strong as the people who stand behind it.

"Did you know that the global ultra-low temperature freezer market is expected to reach $635.4 million by 2027, growing at a CAGR of 5.2% from 2020 to 2027? (Allied Market Research).

This staggering growth underscores the critical importance of ultra-low temperature monitoring in today's research, pharmaceutical, and healthcare sectors.

Maintaining precise temperatures is vital for preserving the integrity of sensitive biological samples, medications, and other materials. Failure to do so can lead to costly losses and setbacks.

That's where ultra-low freezer temperature monitors come in - they provide real-time data, alerts, and peace of mind.

In this comprehensive guide, we'll explore the key features, benefits, and considerations for optimizing your ultra-low temperature monitoring systems, data loggers, and cryogenic freezer tracking solutions."

Ultra Low-Temperature Monitoring Systems

Ultra-low temperature monitoring systems not only ensure compliance but also support research integrity by preserving sample conditions during extended storage periods.

Laboratories and pharmaceutical facilities rely on such systems to eliminate the risk of accidental temperature fluctuations, which can compromise entire projects or product lines.

Sonicu's advanced technology ensures consistent, automated oversight, offering facilities an effective way to maintain operational excellence while focusing on innovation and discovery.

Ultra-low temperature monitoring systems are essential for ensuring compliance with industry regulations and maintaining the viability of valuable samples. Here are some key points to consider:

Importance of Temperature Monitoring

- Ensures compliance with strict industry standards for storing sensitive materials

- Maintains the integrity of biological samples, pharmaceutical products, and research materials

- Prevents costly losses due to temperature fluctuations or equipment failures

Key Features to Look For

- Real-time monitoring capabilities for immediate alerts when temperatures exceed set thresholds

- Cloud-based data storage for secure, remote access and long-term record keeping

- Seamless integration with existing laboratory information management systems (LIMS)

Benefits of Automated Monitoring

- Eliminates human error associated with manual temperature checks and logging

- Increases efficiency by allowing staff to remotely monitor multiple freezers simultaneously

- Provides a complete audit trail for regulatory compliance and quality assurance

Sonicu understands the critical nature of ultra-low temperature monitoring. That's why they offer advanced sensors specifically designed for -80°C freezers and cryogenic environments.

These sensors feature real-time alerts and automated compliance reporting through the SoniCloud platform, ensuring the integrity of your valuable samples 24/7.

Freezer Temperature Data Logger

The role of data loggers extends beyond simple temperature recording; they are integral to proactive risk management.

By analyzing historical data trends, facilities can identify recurring issues and optimize storage practices to mitigate potential risks.

Sonicu’s data loggers enhance this capability, enabling users to extract actionable insights while maintaining detailed, audit-ready records for internal and external reviews.

Modern data loggers play a transformative role in ensuring operational transparency. By integrating seamlessly with digital platforms like Sonicu’s SoniCloud, these devices offer a centralized view of multiple storage units, making it easier to oversee complex operations.

Furthermore, data loggers enhance traceability, allowing teams to link temperature conditions to specific events or incidents. This level of detail not only supports compliance audits but also enables better resource planning and preventative maintenance.

This dual functionality makes data loggers a cornerstone of advanced freezer management strategies.

In addition to aiding refrigeration temperature monitoring, Sonicu plays a vital role for organizations in other industries such as Ohio University and others including:

- Healthcare: Nurses respond to our alerts to keep your medicine safe

- Life Science/Lab: Lab directors rely on our alerts to protect priceless research

- Universities: Research and science department heads rely on our alerts to keep research and classroom labs safe.

- Food Service: Food distributors rely on our tech to protect your dinner

Temperature data loggers are small devices that continuously record temperatures over time. They're essential tools for ultra-low freezer monitoring. Let's take a closer look:

What is a Data Logger?

- A device that automatically records temperature at set intervals for later analysis

- Available in various types, such as USB, wireless, or ethernet-connected

- Ideal for monitoring ultra-low freezers, cryogenic storage, and cold rooms

Key Considerations for Selection

- High accuracy and resolution to capture minute temperature changes

- Long battery life and ample data storage for extended monitoring periods

- Ease of use, with user-friendly software for configuration and data retrieval

Integration Capabilities

- Compatibility with existing monitoring systems and cold storage temperature monitoring solutions

- Ability to export data in various formats for further analysis and reporting

- Option to set alarms and notifications for out-of-range temperatures

Sonicu's wireless temperature data loggers are purpose-built for ultra-low temperature environments.

The SoniShield Duo system supports multiple sensor inputs, onboard data storage, and seamless connectivity via WiFi or cellular networks.

This ensures data continuity even during network interruptions.

Ultra Low Freezer Temperature Tracking

Ultra-low temperature tracking systems are pivotal for dynamic operational settings where conditions can change rapidly.

Sonicu’s tracking solutions provide lab managers and staff with a complete ecosystem of tools to ensure sample protection.

Real-time dashboards and automated alerts minimize the time between detection and action, safeguarding high-value materials and reducing costly interruptions in research or production workflows.

Real-time temperature tracking is crucial for safeguarding the contents of ultra-low freezers.

Here's what you need to know:

Significance of Real-Time Tracking

- Allows for quick response to temperature deviations, preventing sample spoilage

- Provides a continuous record of freezer performance for quality control and audits

- Helps identify potential equipment issues before they lead to costly failures

Advanced Tracking Solutions

- Customizable alerts via email, SMS, or phone calls for immediate notification

- Intuitive dashboards for at-a-glance monitoring of multiple freezers

- Automated reports for effortless compliance documentation

Implementing Best Practices

- Establishing standard operating procedures (SOPs) for temperature monitoring

- Training staff on proper use and maintenance of monitoring equipment

- Regularly calibrating sensors to ensure accuracy and reliability

Sonicu's tiered alarming system is a game-changer for ultra-low freezer monitoring. With customizable thresholds and escalatable alarms, you can reduce alarm fatigue while ensuring the right people are notified promptly.

This level of flexibility and reliability is vital for maintaining sample integrity.

Cryogenic Freezer Temperature Monitoring

Cryogenic monitoring demands equipment designed to handle the most extreme conditions.

Sonicu’s cryogenic solutions not only address these needs but also incorporate fail-safe measures to ensure uninterrupted monitoring.

By integrating real-time liquid nitrogen (LN2)-level monitoring with temperature data, these systems deliver a holistic view of storage conditions.

This level of control is critical for biobanks and research facilities that depend on precise, long-term preservation.

Cryogenic freezers, which operate at extremely low temperatures (below -150°C), require specialized monitoring solutions.

Here are the key considerations:

Understanding Cryogenic Temperatures

- Cryogenic temperatures range from -150°C to -273°C (absolute zero)

- Commonly used for long-term storage of biological samples, cell lines, and vaccines

- Liquid nitrogen (LN2) is the most common coolant for cryogenic storage

Critical Monitoring Features

- Sensors that can withstand extremely low temperatures without loss of accuracy

- Redundant monitoring systems to ensure uninterrupted data collection

- Integration with LN2-level monitoring for complete cryogenic storage management

Impact on Research and Safety

- Precise temperature control is essential for preserving sample viability and research integrity

- Monitoring helps prevent safety hazards, such as oxygen depletion, associated with LN2

- Proper monitoring is crucial for compliance with regulatory requirements and best practices

Sonicu offers tailored cryogenic monitoring solutions for liquid nitrogen dewars and -150°C freezers. These systems are designed for medical labs, research facilities, and biobanks where precise temperature control is paramount.

With NIST-traceable calibration and 21 CFR Part 11-compliant software, you can trust Sonicu to safeguard your valuable cryogenic samples.

.

-80°C Freezer Temperature Alarm System

A -80°C alarm system is not just a protective measure; it’s an essential tool for operational reliability.

Sonicu's systems ensure that users are always informed of storage conditions, even in the event of power failures or network disruptions.

By integrating multi-channel alerts with intuitive configuration options, these alarms help organizations avoid the consequences of missed excursions, safeguarding samples and reducing downtime associated with corrective actions.

Temperature alarms for -80°C freezers are a critical safeguard against unforeseen disruptions.

Sonicu’s solutions go beyond standard notifications by offering customizable escalation protocols that ensure the right personnel are informed at the right time.

This reduces response times and enhances accountability, enabling teams to address issues before they escalate.

Additionally, with built-in redundancy features, these alarms maintain reliability even during power outages, ensuring uninterrupted protection for sensitive samples.

A reliable alarm system is a must-have for any -80°C freezer monitoring setup.

Here's what you should know:

Role of Alarm Systems in Temperature Monitoring

- Provides immediate notification of temperature excursions, allowing for swift corrective action

- Helps maintain the integrity of sensitive samples, preventing costly losses

- Ensures compliance with regulatory guidelines and internal quality control standards

Features to Ensure Reliability

- Multiple notification methods (audible, visual, email, SMS) for failsafe alerting

- Battery backup and redundant sensors to maintain monitoring during power outages

- Compatibility with remote monitoring systems for 24/7 oversight

Best Practices for Alarm Configuration

- Setting appropriate temperature thresholds based on sample type and regulatory requirements

- Establishing a clear escalation protocol for alerts to ensure prompt response

- Regularly testing alarm systems to verify functionality and staff preparedness

Sonicu's freezer temperature alarm system is a comprehensive solution for -80°C freezer monitoring.

With customizable alerts, multi-channel notifications, and a user-friendly interface, you can have peace of mind knowing your critical samples are safeguarded around the clock.

Plus, the system seamlessly integrates with SoniCloud for secure, remote monitoring from anywhere, at any time..

Conclusion

In conclusion, ultra-low freezer temperature monitoring is a critical aspect of many industries, from pharmaceutical development to biomedical research.

By implementing robust monitoring systems, reliable data loggers, and real-time tracking solutions, organizations can ensure the integrity of their valuable samples, maintain regulatory compliance, and prevent costly losses.

As a trusted leader in environmental monitoring, Sonicu offers a range of cutting-edge solutions tailored for ultra-low temperature applications.

From advanced sensors and wireless data loggers to user-friendly software and 24/7 support, Sonicu has everything you need to optimize your ultra-low freezer monitoring program.

Tyner Pond has entrusted Sonicu and received these top features:

- American-based customer service and tech support

- Redundancy of power/connectivity to protect data integrity

- SNAP calibration service for NIST compliance

- Hardware assembled in the United States

- Built on AWS Cloud for simplicity, speed, reliability, and scalability

By embracing the latest advancements in ultra-low freezer monitoring, organizations can streamline their operations while enhancing reliability and compliance.

Sonicu’s solutions are designed to adapt to evolving industry demands, offering scalability and ease of integration across various applications.

Whether in research, healthcare, or pharmaceuticals, partnering with Sonicu means gaining not just cutting-edge technology but also a dedicated team committed to your success.

With Sonicu, you can future-proof your monitoring systems and protect your most valuable assets with confidence.

Don't leave your critical samples to chance.

Contact Sonicu today to learn how their expert team and innovative products can help you achieve unparalleled temperature monitoring and peace of mind.

American-based Customer Support: Robust & Reliable High Touch Service

Software and technology is only as good as the people who stand behind it.

At Sonicu, that means our team of American-based customer success managers who are never more than a phone call away to help field and fix any service issues.

Our probes and sensors are placed in demanding frozen environments and our software literally sends billions bits of data monthly, meaning there’s always the potential for a hiccup on either the hardware or software.

We are committed to fielding every customer service request promptly and addressing our customer’s concerns promptly and professionally.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

How IU Health

consolidated all of its pharmacy monitoring needs

into one cloud-based platform serving dozen of locations.