Warehouse and Cold Storage

If you are looking for temperature monitoring for warehouse and cold storage facilities that helps you and your team eliminate manual logging, improve compliance readiness, and protect all your temperature-sensitive assets, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts to protect assets

- Compliance: Automated reports

- Efficiency: Reduced Manual Logging

And what makes us different?

- Lifetime Warranty: Never buy hardware again!

- Unlimited Users: Scale across your entire org

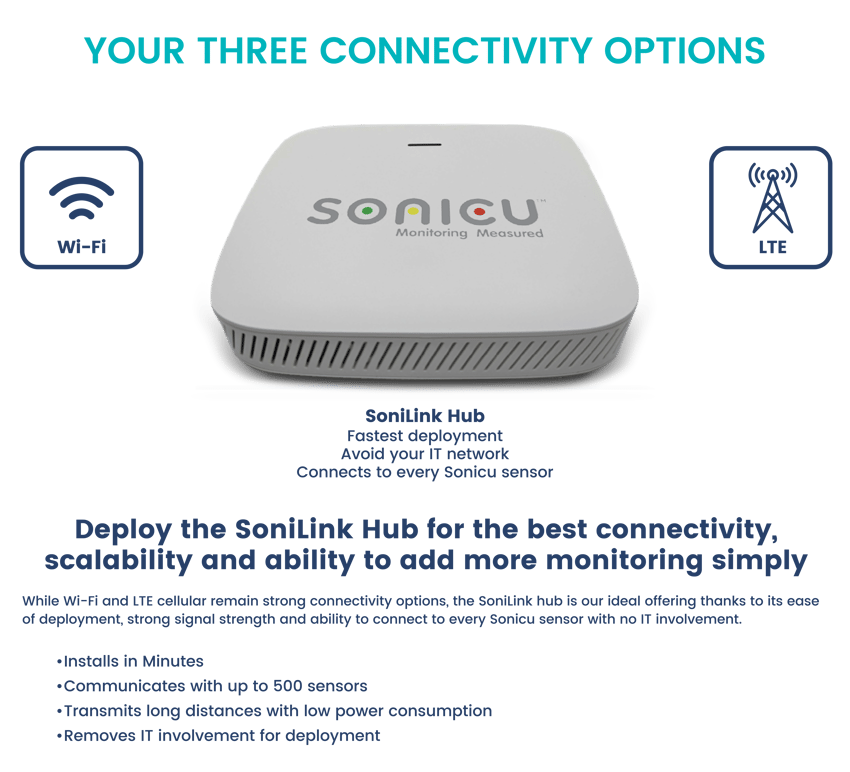

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

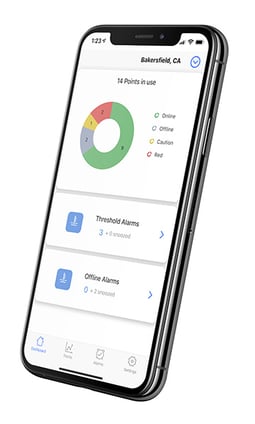

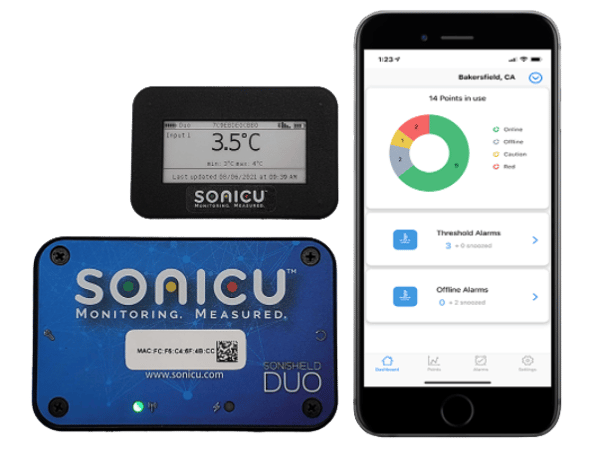

- Mobile App: 500 Freezers in your pocket

All American made and supported!

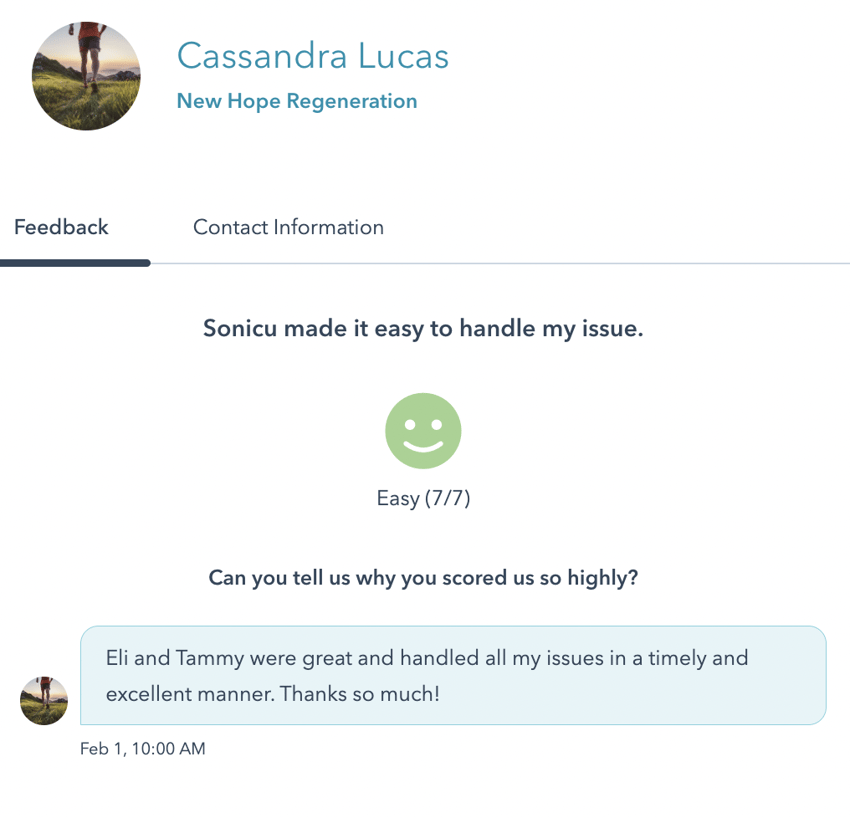

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

Temperature Monitoring for Warehouse and Cold Storage

Some of the finest names in healthcare, including Indiana University Health, University of Michigan Health System, and Stanford University rely on Sonicu to provide a robust and continuous environmental monitoring system, including temperature, humidity, air pressure, and more.

These respected healthcare and research brands turn to Sonicu for four primary reasons:

- Real-Time Monitoring: the sensors collect temperature, humidity, air pressure data, and more, and transmit it wirelessly to SoniCloud - our cloud-based platform.

- Operational Efficiency: Virtually eliminate the need for tedious and costly manual logging

- Compliance Automation: Respond to any regulatory audit or inspection in a few clicks with our reports section

- Asset Protection: Detect and respond to any threshold that can threaten anything perishable: food, drugs, vaccines, research, etc.

Our customers stay with us thanks to our American-based customer support, which is never more than a phone call away. While our technology is intuitive and powerful, we know it’s only as strong as the people who stand behind it.

Did you know that the global cold chain market is expected to reach $628.26 billion by 2028, according to a report by Grand View Research?

As industries such as food service, pharmaceuticals, and biotechnology continue to expand, the importance of effective warehouse and cold storage solutions becomes increasingly evident.

In this comprehensive guide, we'll explore the critical role of temperature-controlled warehousing, cold storage logistics, and the innovative solutions provided by industry leaders like Sonicu.

The Growing Need for Cold Storage Solutions

With the increasing demand for perishable goods, maintaining optimal storage conditions has never been more crucial. Whether it’s fresh produce, dairy, seafood, or life-saving vaccines, even slight deviations in temperature can compromise product integrity, leading to spoilage, financial losses, and even health risks.

This has driven significant investments in cold storage infrastructure, advanced monitoring technologies, and supply chain optimization to ensure that products remain within safe temperature ranges throughout their journey.

Managing cold storage facilities presents unique challenges, including energy efficiency, regulatory compliance, and supply chain disruptions. Some of these challenges can include:

- High operational costs

- Potential equipment failures

- Need for precise temperature monitoring

All of these require businesses to adopt innovative solutions to stay competitive.

Moreover, the regulatory landscape continues to evolve, with stricter guidelines from organizations such as the FDA, CDC, and WHO, making compliance a top priority for businesses that handle temperature-sensitive products.

Sonicu is at the forefront of cold chain innovation, offering real-time monitoring systems that ensure precise temperature control and compliance with industry standards.

Our advanced sensor technology provides automated alerts and data logging, reducing the risk of spoilage and regulatory violations. With cloud-based access, businesses can monitor their cold storage environments remotely, enhancing operational efficiency and peace of mind.

As the cold chain industry continues to evolve, investing in state-of-the-art monitoring and storage solutions will be key to ensuring product safety, reducing waste, and optimizing logistics.

Warehouse Storage Solutions

Efficient warehouse storage is the backbone of any thriving supply chain operation. Maximizing space utilization and streamlining inventory management processes are essential for boosting productivity and minimizing costs.

When designing a warehouse storage solution, several key factors must be considered:

- Shelving and Racking Systems: Selecting the appropriate shelving and racking systems based on product types, sizes, and storage requirements

- Options range from traditional pallet racking to more specialized systems like drive-in or push-back racks, which maximize space efficiency and improve accessibility

- Choice of racking system should align with inventory turnover rates, weight capacity, and ease of retrieval

- Floor Space Optimization: Analyzing the available floor space and determining the most efficient layout for maximum storage capacity

- I.e. utilizing vertical space with mezzanine levels to expand storage without increasing the facility’s footprint

- Strategic placement of high-demand inventory closer to shipping and receiving areas can also improve workflow efficiency

- Automation Integration: Incorporating automation technologies can significantly enhance the efficiency and accuracy of warehouse operations

The Role of Technology in Warehouse Optimization

To optimize warehouse storage, leveraging advanced technology is key. Inventory management systems play a pivotal role in tracking stock levels, monitoring product movement, and generating real-time data insights.

These systems help prevent overstocking or stockouts, improving order fulfillment accuracy and overall operational efficiency.

By integrating these systems with wireless monitoring solutions like those offered by Sonicu, businesses can ensure that their products are stored under optimal conditions while minimizing the risk of losses due to temperature fluctuations or equipment malfunctions.

Sonicu’s real-time monitoring solutions provide businesses with critical data on environmental conditions such as temperature, humidity, and air quality.

These insights enable warehouse managers to take proactive measures to protect sensitive goods, reduce waste, and ensure regulatory compliance. By continuously monitoring environmental conditions such as temperature, humidity, and air quality, businesses can mitigate risks associated with product spoilage, contamination, and equipment failure.

This level of oversight is particularly crucial for industries like pharmaceuticals, biotechnology, and food distribution, where even minor fluctuations in storage conditions can have significant consequences.

With cloud-based access and automated alerts, Sonicu helps businesses maintain a high-performance warehouse environment, ultimately improving supply chain resilience and operational reliability.

Remote monitoring allows stakeholders to track real-time data from anywhere, ensuring immediate response to potential issues.

Additionally, historical data analytics provide valuable insights for optimizing storage conditions, reducing energy consumption, and improving workflow efficiency.

As warehousing demands continue to evolve, adopting innovative monitoring and inventory management solutions will be crucial for staying competitive in today’s fast-paced logistics landscape. Businesses that integrate smart technology into their operations will not only improve compliance and efficiency but also enhance overall supply chain agility.

In an era of increasing consumer expectations and regulatory scrutiny, leveraging advanced monitoring solutions like Sonicu will help companies achieve long-term success and sustainability in cold storage and warehouse management.

In addition to aiding warehouse and cold storage environments, Sonicu plays a vital role for organizations in other industries such as Ohio University and others including:

- Healthcare Temperature Monitoring: Nurses respond to our alerts to keep your medicine safe

- Pharmacy and Laboratory Temperature Monitoring: Lab directors rely on our alerts to protect priceless research

- University Research Temperature Monitoring: Research and science department heads rely on our alerts to keep research and classroom labs safe.

- K-12 Food Service Monitoring: Food distributors rely on our tech to protect your dinner

Cold Storage Logistics

For industries dealing with temperature-sensitive products, cold storage logistics is a critical component of the supply chain. Maintaining the integrity and safety of perishable goods throughout transportation and storage is essential for regulatory compliance and customer satisfaction.

This involves precise temperature monitoring, timely interventions, and efficient handling practices to minimize spoilage and ensure quality.

Advanced technologies, such as IoT-enabled sensors, allow real-time tracking, enhancing visibility and reducing potential risks.

Cold storage logistics also supports sustainability by optimizing energy use and reducing waste, contributing to cost savings while meeting the growing demand for safe, fresh products.

When planning cold storage logistics, consider the following:

- Temperature-Controlled Transportation: Utilizing refrigerated trucks, containers, or air cargo solutions is necessary to maintain the required temperature range during transit

- Partnering with reliable logistics providers who specialize in cold-chain transportation is crucial

- Stakeholder Coordination: Effective communication and coordination among suppliers, distributors, and retailers are vital for ensuring a seamless cold chain

- Establishing clear protocols and contingency plans helps mitigate potential disruptions

- Regulatory Compliance: Adhering to industry-specific regulations and guidelines, such as the Food Safety Modernization Act (FSMA) or Good Distribution Practices (GDP), is mandatory for cold storage logistics

- Staying up-to-date with evolving regulations is essential.

To optimize cold storage logistics, implementing IoT-based monitoring systems is highly recommended. Sonicu's cold chain monitoring solutions provide real-time visibility into temperature, humidity, and other critical parameters throughout the supply chain.

With automated alerts and comprehensive reporting capabilities, businesses can proactively address any deviations and ensure the quality and safety of their products.

Temperature-Controlled Warehousing

Temperature-controlled warehousing is the cornerstone of preserving the integrity of perishable goods and sensitive materials. Maintaining precise temperature zones and ensuring energy efficiency are essential for cost-effective operations.

When designing a temperature-controlled warehouse, consider the following aspects:

- Temperature Zoning: Distinct temperature zones within the warehouse to accommodate different product requirements, such as separate areas for refrigerated, frozen, and ambient storage

- Proper zoning helps prevent cross-contamination, enhances operational efficiency, and ensures compliance with industry regulations.

- Energy Efficiency: Implementing sustainable practices such as proper insulation, energy-efficient lighting, and advanced refrigeration systems reduces energy consumption and operational costs

- High-performance insulation materials, motion-activated LED lighting, and solar-powered refrigeration units are some of the innovations that contribute to a greener, more cost-effective cold storage facility

- Monitoring and Maintenance: Regular monitoring and maintenance of refrigeration equipment is crucial to ensure optimal performance and prevent costly breakdowns.

- Utilizing remote temperature monitoring systems streamlines this process, reducing human error and allowing real-time tracking of environmental conditions

Regulatory compliance is a key factor in cold storage management. Warehouses handling pharmaceuticals, food, and biotechnology products must adhere to guidelines from agencies such as the FDA, CDC, and USDA. .

Proper documentation, automated data logging, and regulatory audits ensure that products remain within safe temperature ranges, reducing risks of spoilage and contamination.

Sonicu's state-of-the-art temperature monitoring solutions are specifically designed for temperature-controlled warehousing. With wireless sensors, cloud-based data storage, and intuitive dashboards, businesses can easily monitor and manage their refrigerated storage units.

Real-time alerts notify designated personnel of any temperature excursions, enabling swift corrective actions to prevent product spoilage.

Additionally, Sonicu’s predictive analytics capabilities help warehouse managers anticipate potential issues before they escalate, improving efficiency and minimizing downtime.

By integrating Sonicu’s advanced monitoring technology, businesses can enhance operational reliability, meet regulatory requirements, and reduce waste, ultimately ensuring the highest level of product integrity within their temperature-controlled warehouses.

Frozen Goods Storage

Storing frozen goods requires specialized equipment and stringent temperature control to maintain product quality and prevent spoilage. This includes using commercial freezers, temperature sensors, and alarms to ensure consistent cooling. Proper storage techniques, such as organizing products for airflow and monitoring storage conditions, are essential to prevent freezer burn and deterioration.

When managing frozen goods storage, consider the following factors:

- Storage Units: Selecting appropriate storage units (walk-in freezers, blast freezers, etc.) depending on type and quantity of products being stored

- High-volume operations may require automated storage and retrieval systems (AS/RS) for improved efficiency

- Packaging Considerations: suitable packaging materials that can withstand freezing temperatures and prevent freezer burn are essential

- Barrier films, vacuum-sealed bags, and moisture-resistant containers can help maintain product quality over extended periods

- Inventory Management systems are crucial for tracking stock levels, expiration dates, and product movement

- FIFO (First In, First Out) and FEFO (First Expired, First Out) strategies ensure optimal stock rotation and minimize waste.

Sonicu's commercial freezer temperature monitoring systems provide comprehensive oversight of frozen goods storage. With advanced sensors and intuitive software, businesses can ensure that their frozen products remain within the required temperature range. Customizable alerts notify staff of any temperature deviations, enabling prompt action to prevent product loss.

Additionally, Sonicu’s cloud-based reporting tools assist with regulatory compliance, providing valuable insights for improving cold storage operations. These real-time analytics allow businesses to identify trends, optimize energy consumption, and streamline logistics, ultimately enhancing overall efficiency and cost savings.

As the frozen food industry continues to grow, leveraging advanced monitoring technology like Sonicu’s solutions will be essential for maintaining quality, reducing waste, and ensuring seamless supply chain operations.

Cold Chain Management

Effective cold chain management involves coordinating the entire temperature-controlled supply chain, from sourcing to final delivery. Ensuring that products remain at the required temperature throughout transit is essential for maintaining quality, safety, and regulatory compliance.

It also requires real-time monitoring, timely intervention in case of deviations, and reliable packaging to minimize risks. Proper staff training, maintaining equipment, and using appropriate transport methods contribute to the success of the cold chain process.

By adhering to these standards, businesses can safeguard products, reduce losses, and meet consumer demands for fresh and safe goods.

Key Considerations for Cold Chain Management include:

- End-to-End Visibility: Implementing a comprehensive monitoring system that tracks temperature, humidity, and location data across the entire cold chain

- Collaboration and Communication: Strong partnerships and open communication among suppliers, distributors, and retailers for a seamless cold chain

- Data Analytics: Leveraging data analytics tools to gain insights into cold chain performance, identify bottlenecks, and optimize performance

Regulatory compliance is a fundamental aspect of cold chain logistics, as organizations must adhere to strict guidelines set by agencies like the FDA, CDC, and WHO.

Temperature-sensitive goods such as pharmaceuticals and biologics require meticulous documentation and tracking to ensure compliance with Good Distribution Practices (GDP) and Good Manufacturing Practices (GMP).

Non-compliance can result in product recalls, financial penalties, and damage to a company’s reputation. Advanced monitoring solutions help businesses stay compliant by automating record-keeping and ensuring continuous adherence to required conditions.

Sonicu’s cold chain management solutions offer end-to-end visibility and control. With IoT-enabled sensors, real-time monitoring, and advanced analytics capabilities, businesses can optimize their cold chain operations.

Predictive maintenance features help identify potential equipment failures before they occur, reducing downtime and ensuring uninterrupted cold chain integrity.

By detecting anomalies in refrigeration systems and alerting maintenance teams before issues escalate, businesses can prevent costly disruptions and extend the lifespan of their equipment.

Additionally, Sonicu’s cloud-based dashboards allow stakeholders to

Predictive maintenance features help identify potential equipment failures before they occur, reducing downtime and ensuring uninterrupted cold chain integrity.

By detecting anomalies in refrigeration systems and alerting maintenance teams before issues escalate, businesses can prevent costly disruptions and extend the lifespan of their equipment.

Additionally, Sonicu’s cloud-based dashboards allow stakeholders to remotely track temperature fluctuations, receive instant alerts, and generate compliance reports with ease.

This level of real-time oversight enables quick decision-making, ensuring that any deviations from required storage conditions are promptly addressed to maintain product safety and regulatory compliance.

By integrating Sonicu’s smart monitoring solutions, businesses can enhance operational efficiency, minimize product loss, and strengthen the reliability of their cold chain logistics.

Automated data logging simplifies record-keeping for audits and inspections, as well as providing insights for optimizing storage conditions and energy consumption. As demand for temperature-controlled storage grows, investing in innovative technology will be crucial for maintaining quality and ensuring supply chain resilience.

Companies that leverage advanced monitoring solutions will not only improve compliance and reduce waste but also gain a competitive edge by ensuring consistent product quality and delivery reliability in an increasingly demanding marketplace.

Conclusion

In today’s complex and fast-paced supply chain landscape, effective warehouse and cold storage solutions are vital for businesses dealing with temperature-sensitive products.

Maintaining precise environmental conditions is essential for preserving product integrity, ensuring regulatory compliance, and minimizing waste.

By implementing state-of-the-art technologies, optimizing processes, and partnering with industry experts like Sonicu, companies can enhance efficiency, reduce costs, and ensure the highest levels of product quality and safety.

Advanced monitoring systems help businesses proactively address potential issues, reducing downtime and preventing costly product losses.

From warehouse storage solutions to cold chain logistics and temperature-controlled warehousing, Sonicu’s comprehensive suite of monitoring and management tools empowers businesses to streamline their operations and mitigate risks.

Wireless sensors, cloud-based data storage, and automated alerts allow for seamless monitoring of storage conditions, ensuring that temperature fluctuations are detected and addressed immediately.

With real-time data, actionable insights, and expert support, Sonicu helps organizations navigate the complexities of cold storage and achieve supply chain excellence. By leveraging predictive analytics and automation, businesses can optimize inventory management, improve energy efficiency, and enhance operational reliability.

As the demand for temperature-controlled storage continues to rise, investing in innovative cold chain solutions will be key to maintaining a competitive edge and ensuring long-term success.

To learn more about how Sonicu can revolutionize your warehouse and cold storage operations, visit our website or contact our team today.

Our experienced professionals are ready to provide tailored solutions that meet your specific needs and help you stay ahead in an increasingly competitive market.

American-based Customer Support: Robust & Reliable High Touch Service

Software and technology is only as good as the people who stand behind it.

At Sonicu, that means our team of American-based customer success managers who are never more than a phone call away to help field and fix any service issues.

Our probes and sensors are placed in demanding frozen environments and our software literally sends billions bits of data monthly, meaning there’s always the potential for a hiccup on either the hardware or software.

We are committed to fielding every customer service request promptly and addressing our customer’s concerns promptly and professionally.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

How IU Health

consolidated all of its pharmacy monitoring needs

into one cloud-based platform serving dozen of locations.