Wireless Food Safety Monitoring

If you are looking for a wireless food safety monitoring system that helps you and your team eliminate manual logging, improve compliance readiness, and protect all your temperature-sensitive assets, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts via text, email, push notifications and phone calls to protect your precious assets

- Compliance: Automated compliance reports

- Efficiency: Reduced Manual Logging and time spent on reports

- Robust Redundancy: Battery Backup and DataSync for reliable data continuity

And what makes us different?

- Lifetime Warranty: Ongoing warranty included with monitoring subscription

- Unlimited Users: Scale across your entire organization

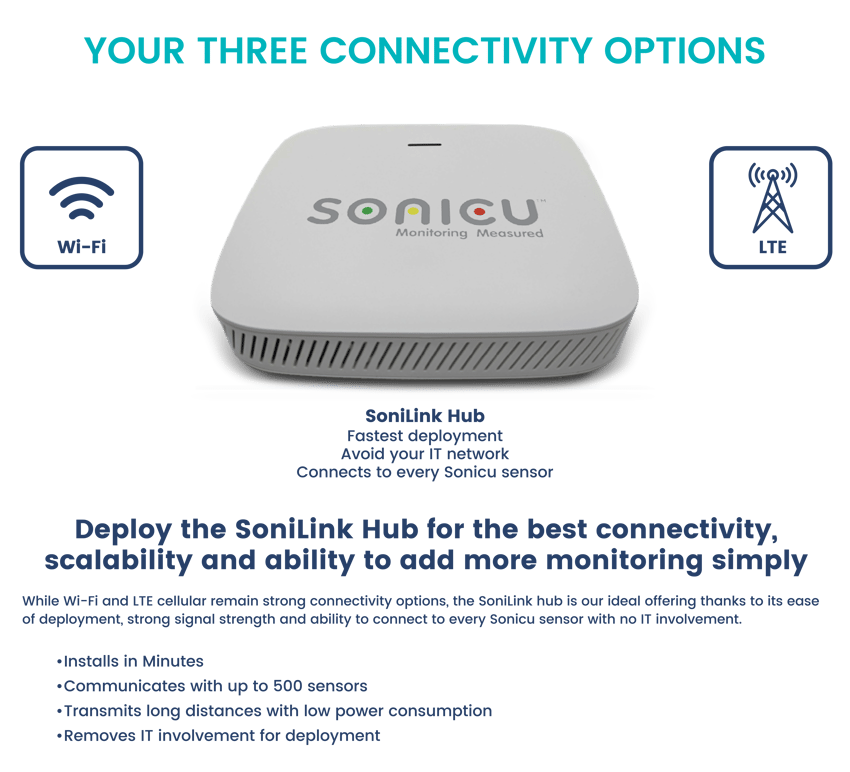

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

- Mobile App: 500 Freezers in your pocket

- Facility monitoring: Simple to add water leak, door open, occupancy, and even IAQ monitoring

Engineered in Indiana with U.S.-based support.

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

Wireless Food Safety Monitoring

Chefs Commissary, Piazza Produce, Smithfield, US Foods, and more food industry organizations rely on Sonicu to provide a robust and continuous environmental monitoring system, including, temperature, humidity, air pressure and more.

Sonicu offers many benefits for organizations to have peace of mind while protecting their most valuable assets.

- Real-Time Monitoring: the sensors collect temperature, humidity, air pressure data and more, and transmit it wirelessly to SoniCloud - our cloud-based platform.

- Operational Efficiency: Virtually eliminate the need for tedious and costly manual logging

- Compliance Automation: Respond to any regulatory audit or inspection in a few clicks with our reports section

- Asset Protection: Detect and respond to any threshold that can threaten anything perishable: food, drugs, vaccines, research, etc.

Our customers stay with us thanks to our American-based customer support, which is never more than a phone call away. While our technology is intuitive and powerful, we know it’s only as strong as the people who stand behind it.

Wireless Food Safety Monitoring Systems: All You Need to Know

Measuring and tracking temperature, humidity, air quality, pressure and other environmental conditions in the food industry is crucial for ensuring food safety.

Sonicu plays a significant role in preventing the growth of harmful microorganisms, preserving food quality, and complying with food safety regulations.

From cold and frozen temperature storage to ambient conditions like relative humidity and air pressure differential to specific needs like CO2 and VOC monitoring, Sonicu provides a full suite of monitoring solutions.

Temperature and humidity are critical factors influencing the growth of bacteria, yeasts, molds, and other microorganisms in food. By tracking these conditions, food processors can ensure that foods are stored and transported within safe temperature ranges, preventing the rapid growth of harmful pathogens that can cause foodborne illnesses.

Besides temperature and humidity, below are other conditions that must be monitored in the food industry.

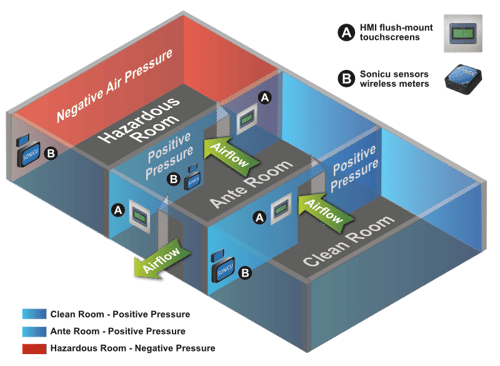

Differential Air Pressure

Contaminated air can introduce harmful microorganisms and contaminants to food processing areas. Keeping track of air quality, including the presence of airborne particles, molds, and bacteria, is crucial to maintaining hygienic conditions in processing facilities.

Pressure changes in food packaging can impact the integrity of the package seal and, consequently, the shelf life of the product. Monitoring pressure is especially important in products with a gas-producing potential, such as fermented foods and carbonated beverages.

Sonicu's differential air pressure kit includes everything you need to monitor and maintain the required air pressure, while providing compliance and easy reporting for regulated environments.

The features included in this kit are:

- On-site monitoring via panel displays

- 24/7 remote monitoring from anywhere using any smart device or desktop

- Configurable alarms ensure pre-set differentials are maintained

- SoniCloud, cloud-based platform

- Continuous data logging

- Automatically generated reports to meet regulatory standards

Monitoring the time that food spends in various stages of production, transportation, and storage is essential for maintaining freshness and preventing spoilage.

Time-temperature integrators (TTIs) are used to monitor cumulative time-temperature abuse during transportation and storage.

Lastly, monitoring and preventing cross-contamination is critical to avoid the spread of pathogens from one food product to another during processing and handling.

You can learn more about how our software helps compliance professionals in these case studies:

Discount Drug Mart: Power Outage Protection + Compliance Automation

Problem: Transitioning from manual temperature logs and reactive power outage management

Solution: Adopting Sonicu's advanced system for seamless temperature monitoring and real-time power outage alerts across its 77 locations.

Hendricks Health: From Nutrition to the OR

Problem: The need to improve compliance and safety across various departments, starting from nutrition to the operating rooms.

Solution: Upgraded monitoring systems to enhance patient safety and streamline compliance across multiple facilities, including local YMCA rehabilitation facilities.

IU Health: Enterprise Monitoring

Problem: Challenges of using a locally based server and multiple monitoring solutions across departments.

Solution: Transitioned to a single, cloud-based solution with Sonicu to enhance monitoring capabilities across more than a dozen locations and the IU School of Medicine.

We deliver safety, compliance, and efficiency. Simply.

Back to temperature and humidity.

Proper temperature and humidity control help maintain the sensory characteristics and overall quality of food products. For instance, certain foods require specific humidity levels to prevent them from drying out or becoming too moist, which could negatively affect their taste, texture, and appearance.

The food industry is subject to various strict regulations and standards regarding food safety, such as FDA and USDA. Tracking environmental conditions is essential for complying with these regulations, as many of them specify temperature and humidity requirements for specific food products and production processes.

Sonicu streamlines regulatory compliance from private and government agencies including the Joint Commission, FDA, CDC, VFC, State Boards of Pharmacy and local boards of health.

These reports are generated automatically in our cloud-based platform, SoniCloud. All the data captured will be transmitted to the cloud, stored and easily accessible for any further analysis required.

Correct environmental monitoring can extend the shelf life of perishable food items.

By storing products at optimal conditions, spoilage can be minimized, reducing waste and ensuring that consumers receive fresh and safe products.

Accurate tracking of environmental conditions allows for better traceability in the event of a foodborne illness outbreak or product recall.

Determining the source of contamination or quality issues becomes more manageable with Sonicu because all the historic data from the sensors will be stored and available in SoniCloud.

Also, food safety audits are common in the food industry, and having reliable temperature and humidity records demonstrates a commitment to maintaining high standards of food safety.

Reporting for compliance automation with Sonicu is really easy.

Quickly respond to alerts, analyze data and performance and create reports from your dashboard.

Below are use cases where the need for food safety monitoring is more pronounced.

Restaurants and food service establishments rely on Sonicu to track food safety to ensure proper storage and handling of perishable foods to prevent foodborne illnesses.

Case Study:

Chef's Commissary, “Sonicu made it simple for us”.

Food processing plants track food safety conditions to maintain suitable environmental conditions during processing, storage, and transportation to prevent contamination and spoilage.

Monitoring temperature and humidity in the transportation and storage of refrigerated and frozen foods helps to preserve their quality and safety and in turn ensure proper cold chain management.

Food retailers must control temperature and humidity in food display cases to prevent spoilage and ensure product quality for consumers.

In the fresh produce industry, monitoring environmental conditions in storage facilities and transportation helps prevent the growth of pathogens and extend shelf life.

Lastly, ensuring proper temperature control during processing and transportation prevents the growth of harmful bacteria in seafood products.

How Sonicu's wireless food safety monitoring systems meet the measuring and tracking needs of the food industry?

Sonicu's wireless food safety monitoring systems have revolutionized the way the food industry tracks and monitors environmental conditions.

These systems leverage wireless technology to collect and transmit data from various sensors, providing real-time information on critical parameters.

Sonicu's wireless food safety monitoring systems offer real-time data collection and transmission to SoniCloud, our cloud-based platform.

Sonicu offers a comprehensive solution for temperature monitoring by utilizing wireless sensors that can be strategically placed in diverse locations and environments.

These sensors efficiently collect data, which is then transmitted to our cloud-based platform, SoniCloud.

This immediate feedback allows food businesses to respond quickly to any deviations from desired environmental conditions, helping prevent potential issues before they escalate.

From SoniCloud, users can conveniently access and monitor the data remotely through their smart device.

Our systems can be accessed remotely through SoniCloud by food industry professionals to monitor conditions, receive alerts, and analyze data from anywhere, enhancing operational efficiency and responsiveness.

Sonicu has designed alerts and notifications around one simple goal: ensuring you and your team receive the right message at the right time to protect your assets, staff and clients.

When coupled with our dashboard, the Sonicu mobile app serves as your mobile connection to all your sensitive assets and environments. Sonicu's wireless systems can track multiple parameters simultaneously, such as:

- Temperature

- Humidity

- Air pressure, and more.

Having a comprehensive view of these factors ensures a holistic approach to food safety and quality.

The systems can be programmed to generate automated alerts via email, SMS, or app notifications when environmental conditions deviate from predefined thresholds.

These alerts allow for swift action to prevent food safety risks and maintain product integrity.

SoniCloud stores historical data, enabling food industry professionals to analyze trends, identify patterns, correlations and make data-driven decisions. Historical data can be useful for audits, compliance reporting, and process improvement.

Sonicu generates electronic records of environmental data, facilitating compliance with food safety regulations and audit requirements.

The electronic format streamlines record-keeping processes and reduces the risk of manual errors.

Case Study:

Wireless monitoring systems can be integrated into Hazard Analysis and Critical Control Points (HACCP) plans, helping businesses implement preventive controls and maintain food safety standards.

Sonicu's wireless monitoring systems use battery-powered sensors, making them easy to install and move. This feature is especially valuable in large facilities or during transportation, where constant monitoring at different locations is necessary.

Easy to install and configure and supported by live American-based phone support, Sonicu is the affordable, intuitive, and trusted temperature and environmental monitoring solution trusted nationwide.

Additional sensors can be easily deployed without the need for extensive wiring, making scaling up a straightforward process.

SoniCloud provides graphs and charts that facilitates data analysis for the users and customizable reporting features. Analyzing data trends can lead to process optimization, energy savings, and better resource management.

Finally, wireless monitoring systems are generally more reliable and experience less downtime compared to traditional wired systems, ensuring continuous monitoring without interruption.

Sonicu helps you reduce product losses and safeguards the quality and integrity of your most valuable assets.

What are the major pain points in the food industry that Sonicu's wireless food safety monitoring systems resolve effectively?

Sonicu's wireless food safety monitoring solutions effectively address several major pain points across the entire food industry, from farm to fork.

These solutions offer innovative ways to overcome traditional challenges and improve overall food safety, quality, and efficiency.

We provide real-time data on critical parameters such as temperature and humidity, air quality, pressure, and more.

This allows immediate detection of deviations from safe conditions, enabling quick corrective actions to prevent food spoilage, contamination, and potential foodborne illnesses.

The food industry is subject to various regulations and standards to ensure food safety.

Sonicu's wireless tracking systems help businesses comply with these regulations by providing accurate and accessible records of environmental conditions and facilitating audits and regulatory reporting.

Monitoring temperature and humidity during the transportation and storage of perishable goods is essential for maintaining the cold chain.

Sonicu enables continuous tracking of temperature-sensitive products, ensuring that they remain within safe temperature ranges throughout the supply chain.

Sonicu's wireless food safety monitoring aligns well with Hazard Analysis and Critical Control Points (HACCP) principles. It helps identify critical control points, monitor them in real-time, and take preventive measures to minimize food safety risks.

At Sonicu we aid in preserving food quality by maintaining optimal environmental conditions in your facilities.

We help you extend the shelf life of perishable products, reduce waste, and enhance consumer satisfaction with fresh, high-quality goods.

Accurate and accessible environmental data allows for effective traceability in the event of foodborne illness outbreaks or product recalls. This information enables businesses to identify the source of contamination quickly and efficiently.

Also, with Sonicu's wireless monitoring systems, you can optimize resource usage, such as energy and labor. Your staff will be alerted to potential issues promptly sothey can intervene to prevent waste and reduce energy consumption.

You can learn more about how our software helps compliance professionals in these case studies:

Xytex Sperm Bank: Ultra Low Temperature Monitoring

Problem: Frequent false alerts were causing alarm fatigue, threatening the operations at Xytex Sperm Bank.

Solution: Partnered with Sonicu to develop a custom temperature monitoring solution for ULT and cryo temperatures, including probes inside and outside the preservation chambers.

Boy Scouts: Protecting Campers from a Temperamental Walk-in Cooler

Problem: An aging walk-in cooler failed at a remote campground in Ohio, causing significant food loss and logistical challenges for the Boy Scouts.

Solution: Sonicu provided a system that was easy to install, connected with a mobile app, affordable for a non-profit budget, and automated the required manual logging.

Hamilton County, Indiana Health Department: Vaccine Monitoring

Problem: The need to protect vaccines from temperature excursions and meet state compliance requirements with an outdated analog system.

Solution: Implemented a new monitoring system with a mobile app and robust support, enhancing the management of remote COVID-19 vaccination programs.

SoniCloud and our mobile application enables remote access and management of the monitoring system.

This is particularly beneficial for large-scale food processing facilities and companies with multiple locations, allowing centralized control and oversight.

The data collected by wireless monitoring systems can be analyzed to identify trends, correlations, and patterns, empowering data-driven decision-making. This leads to process optimization, improved operational efficiency, and enhanced food safety practices.

Our dashboard provides a clear visibility of which unit, fridge, freezer, etc requires your attention. With this said, your staff members can easily identify where to go and quickly protect your most valuable assets.

By proactively monitoring environmental conditions, wireless monitoring solutions help reduce the risk of product recalls due to compromised food safety or quality issues.

Lastly, implementing robust food safety monitoring systems demonstrates a commitment to consumer safety and quality, increasing consumer confidence in the products and brands.

Trust Sonicu to streamline and enhance your temperature monitoring processes, reducing stress and saving valuable time and money for your business.

There are numerous benefits that you can obtain with Sonicu's wireless food safety monitoring:

- Access to real-time data, enabling immediate responses to deviations from safe environmental conditions, which helps prevent food spoilage and contamination.

- Users can access the system remotely through SoniCloud, our cloud-based platform or our mobile application, allowing for convenient monitoring and management from anywhere.

- Our sensors are easy to install without the need for extensive wiring, and the system can be scaled up or down as needed, making it adaptable to various applications and facility sizes.

- Sonicu's wireless systems are more reliable and experience less downtime compared to wired systems, ensuring continuous monitoring without interruption.

- The data collected by wireless systems can be analyzed to identify trends, correlations, and patterns, leading to data-driven insights for process optimization and improved food safety practices.

- Sonicu facilitates compliance with food safety regulations by providing accurate and accessible reports of environmental conditions, simplifying audit processes.

- Automated alerts and notifications minimize the need for on-site personnel to constantly check environmental conditions, leading to potential labor cost savings.

We give you the freedom to monitor your most valuable assets from anywhere at any time.

Conclusion

In today's fast-paced food industry, ensuring food safety and quality is paramount. The traditional methods of monitoring environmental conditions may not suffice to meet the rigorous demands of modern food processing and transportation.

However, with Sonicu's advanced wireless food safety monitoring systems, businesses can take advantage of real-time data, remote accessibility, and data-driven insights to revolutionize their food safety practices.

The food industry faces ever-increasing demands to ensure food safety and maintain product quality. Embracing wireless food safety monitoring systems is a transformative solution that can address these challenges head-on.

With real-time monitoring, remote accessibility, and data-driven insights, businesses can detect issues proactively and take prompt action, safeguarding their reputation and consumer trust.

Consider implementing a wireless food safety monitoring solution in your business today. Embrace the power of real-time data, streamlined compliance, and enhanced efficiency.

Upgrade your food safety practices, and ensure your products meet the highest quality standards from farm to fork.

Take a step towards a safer and more successful future in the food industry. Contact us now to learn more about how wireless monitoring can transform your food safety practices.

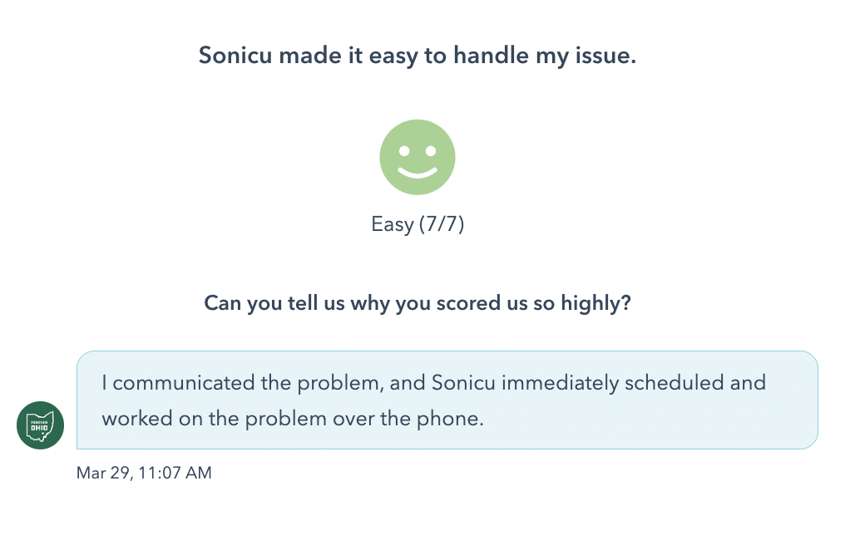

Customer Support: Three Sonicu customer praise the support they rely on to protect their assets and automate compliance

American-based Customer Support: Robust & Reliable High Touch Service

Experience Unparalleled Service with Sonicu's Dedicated Team

At Sonicu, we understand that the true value of software and technology lies in the people who stand behind them.

Our probes and sensors are purposefully designed to withstand the harshest frozen environments, working tirelessly to collect and transmit billions of bits of data every month.

That's why we take pride in our team of dedicated American-based customer success managers, always ready to assist you with any service issues.

With Sonicu, help is just a phone call away, ensuring a seamless experience for our valued customers.

Our customers are highly educated and protect highly valuable assets with our solutions. We boast more than 95 percent customer retention thanks to our reliable hardware, intuitive software and robust customer support.

We are committed to fielding every customer service request promptly and getting our customers online rapidly.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

How IU Health

consolidated all of its pharmacy monitoring needs

into one cloud-based platform serving dozen of locations.