Wireless Monitoring for Pharmaceutical

If you are looking for a cloud-based monitoring system for your pharmaceutical storage equipment that helps you and your team eliminate manual logging, improve compliance readiness, and protect all your temperature-sensitive assets, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts via text, email, push notifications and phone calls to protect your precious assets

- Compliance: Automated compliance reports

- Efficiency: Reduced Manual Logging and time spent on reports

And what makes us different?

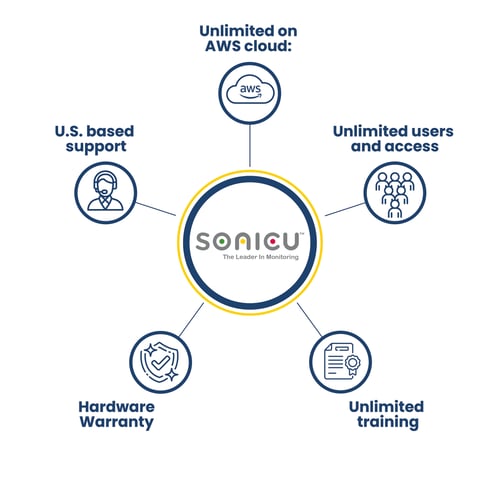

- Lifetime Warranty: Never buy hardware again!

- Unlimited Users: Scale across your entire organization

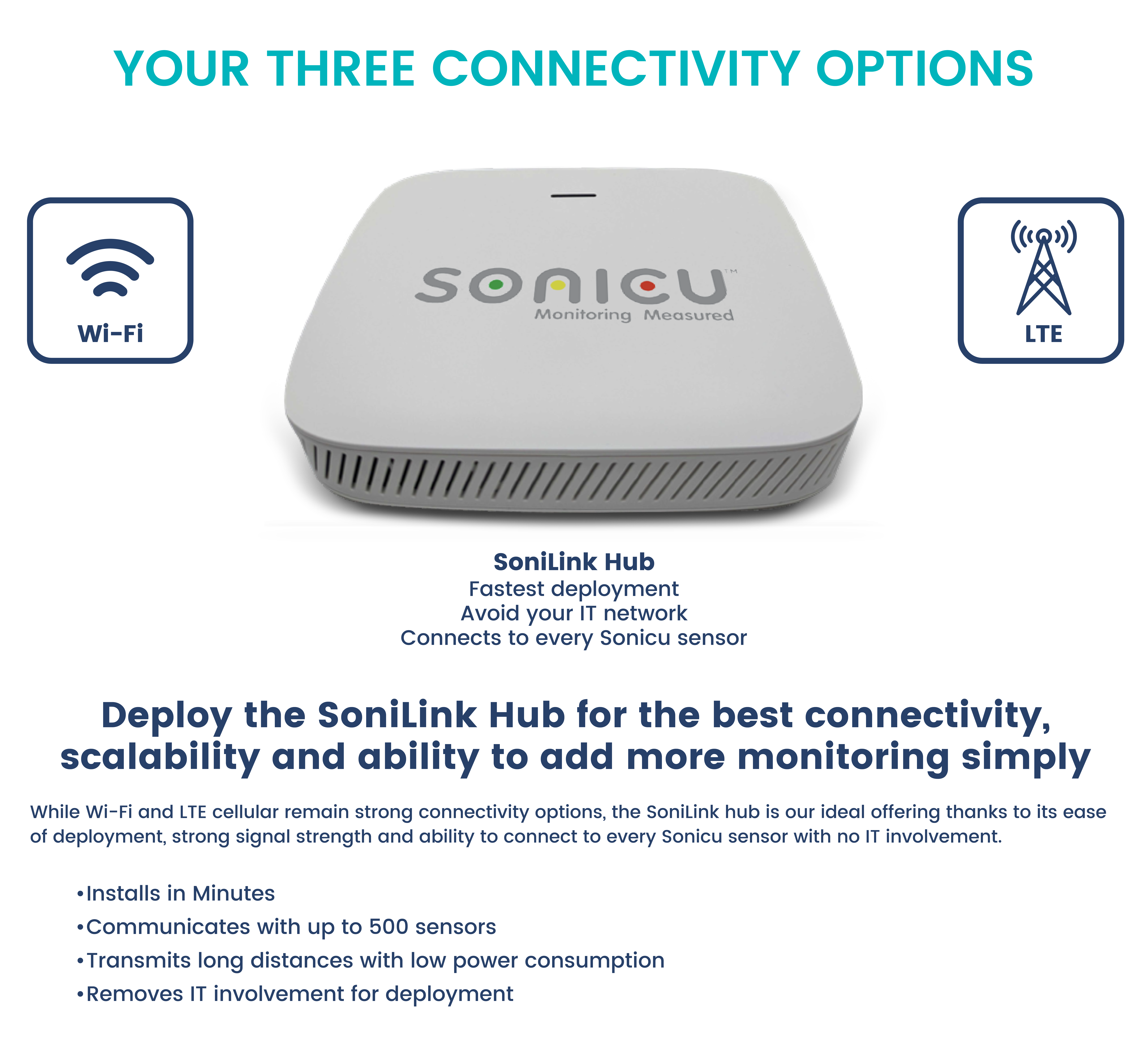

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

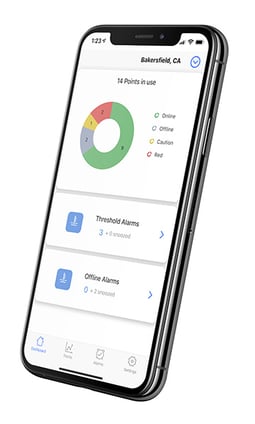

- Mobile App: 500 Freezers in your pocket

- Facility monitoring: Simple to add water leak, door open, occupancy, and even IAQ monitoring

Engineered in Indiana with U.S.-based support.

Pharmaceutical Monitoring

Many medicines and vaccines that are common in many pharmacies require specific conditions to retain optimum efficacy and ensure patient safety. The average pharmacy fridge contains $25,000 in perishable assets.

Pharmaceutical Monitoring BrochureSee What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

- Real-Time Monitoring: The sensors collect temperature data and transmit it wirelessly to Sonicloud - our cloud-based platform.

- Operational Efficiency: Virtually eliminate the need for tedious and costly manual logging

- Compliance Automation: Respond to virtually any regulatory audit or inspection in a few clicks with our reports section

- Asset Protection: Detect and respond to any temperature excursion that can threaten virtually anything perishable: food, drugs, vaccines, research, etc.

We realized there had to be a better way and went in search of technology that could give us that level of monitoring that would keep our patients safe. Sonicu made it easy and we grew across the entire hospital.

Wireless Monitoring for Pharmaceutical

Some of the finest names in healthcare, including Indiana University Health, University of Michigan Health System, and Stanford University, rely on Sonicu to provide a robust and continuous environmental monitoring system, including, temperature, humidity, air pressure and more.

These respected healthcare and research brands turn to Sonicu for four primary reasons:

- Real-Time Monitoring: the sensors collect temperature, humidity, air pressure data and more, and transmit it wirelessly to SoniCloud - our cloud-based platform.

- Operational Efficiency: Virtually eliminate the need for tedious and costly manual logging

- Compliance Automation: Respond to any regulatory audit or inspection in a few clicks with our reports section

- Asset Protection: Detect and respond to any threshold that can threaten anything perishable: food, drugs, vaccines, research, etc.

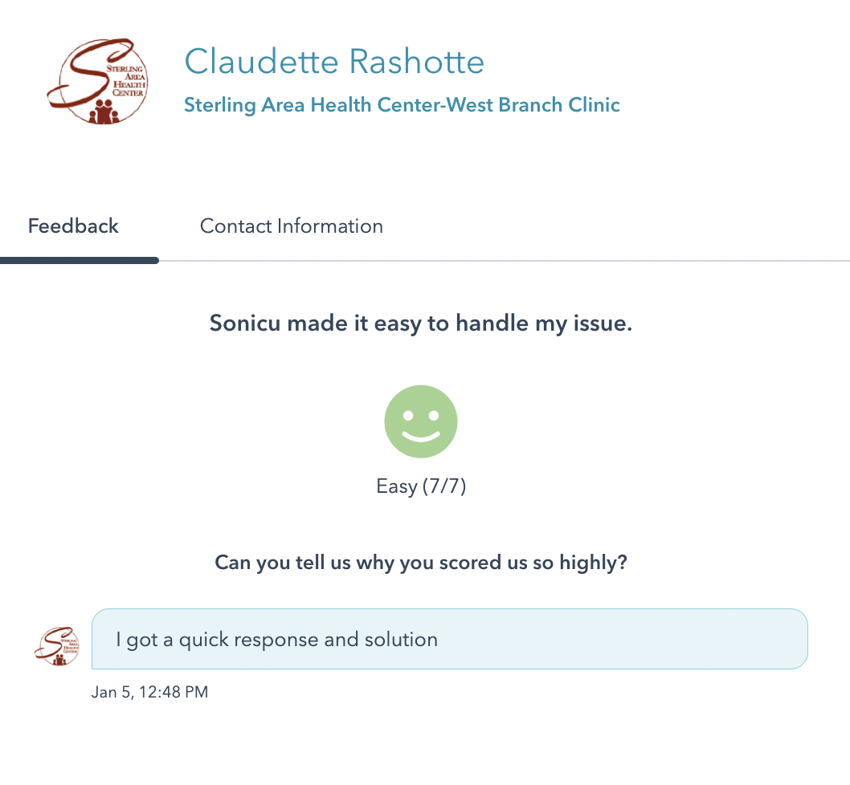

Our customers stay with us thanks to our American-based customer support, which is never more than a phone call away. While our technology is intuitive and powerful, we know it’s only as strong as the people who stand behind it.

An In-Depth Review of Wireless Monitoring for Pharmaceutical Solutions

In the pharmaceutical industry, maintaining proper temperature and environmental conditions is crucial to ensure the quality and integrity of the products throughout the supply chain.

Sonicu can help you protect your most valuable assets by delivering:

- Safety: Alerts to protect your most valuable assets

- Compliance: Automated reports

- Efficiency: Reduced Manual Processes

Below is an overview of the temperature and environmental monitoring needs of each player in the pharmaceutical industry, from manufacturing to distribution and pharmacies.

Manufacturing

Pharmaceutical manufacturers need to monitor and control the temperature in their manufacturing facilities to ensure proper storage and handling of raw materials, active pharmaceutical ingredients (APIs), and finished products.

Manufacturers may also monitor air pressure differentials and humidity to maintain a clean and controlled environment, particularly in areas such as sterile manufacturing, to prevent contamination.

Warehousing and Distribution

During storage and transportation, pharmaceutical products often require specific temperature ranges to maintain their stability and efficacy.

Temperature-controlled storage areas, such as cold rooms or refrigerators, are monitored to ensure products are stored within the recommended temperature ranges.

Monitoring of humidity levels is important to prevent moisture-related degradation of pharmaceuticals. To control particulate contamination, air pressure differentials may be monitored in certain environments, such as clean rooms.

Logistics and Transportation

Temperature monitoring is critical during transportation to ensure that products are not exposed to extreme temperatures that could compromise their quality.

Temperature-controlled vehicles, thermal packaging, or temperature data loggers are commonly used to monitor and record temperature conditions during transit.

While air pressure differentials may not be actively monitored during transportation, maintaining appropriate packaging integrity is crucial to prevent leaks or changes in pressure that could affect the product.

Pharmacies and Dispensing

Pharmacies and dispensing facilities must monitor and control the temperature in their storage areas to ensure the integrity and efficacy of pharmaceutical products before dispensing them to patients.

Humidity levels are typically monitored in storage areas to prevent moisture-related issues, such as degradation or microbial growth. Air pressure differentials may not be extensively monitored in typical pharmacy settings.

It’s worth noting that specific temperature and environmental monitoring requirements may vary depending on the type of pharmaceutical products being handled and local regulatory guidelines.

Manufacturers, distributors, and pharmacies often implement quality management systems and employ various monitoring devices and technologies to meet these requirements and ensure the safety and efficacy of pharmaceuticals throughout the supply chain.

You can learn more about how our software helps compliance professionals in these case studies:

Problem: Data loggers that were not on the cloud and cloud-based solution that only connected via wi-fi

Solution: Cloud-based solution with connectivity in wi-fi AND cellular for maximum flexibility and compliance readiness

Problem: The aging walk-in cooler with a faulty electrical system caused system failure and a loss of $5,000 in food

Solution: Simple and affordable temperature monitoring solution that protects costly food and automates compliance.

How does Sonicu's wireless monitoring systems for pharmaceutical companies meet these requirements and what are their key functions?

Sonicu's wireless monitoring systems for pharmaceutical companies are designed to meet the specific temperature and environmental monitoring needs of the industry.

SoniShield View: Clean Rooms and Compounding Rooms. Pharmacy

To this end, Sonicu offers several key functions to ensure the integrity of pharmaceutical products throughout the supply chain, storage and more!

Sonicu's wireless monitoring systems provide real-time monitoring of temperature and environmental conditions. The sensors continuously measure the desired parameters and transmit the data wirelessly to SoniCloud, Sonicu's cloud-based platform, where data is stored and easily accessible for users.

This enables stakeholders to have immediate visibility into the conditions of their most valuable assets from any smart device and take prompt action if any deviations occur.

SoundCloud allows for remote access to the data. Authorized personnel can access the monitoring system via web-based or mobile apps from anywhere at any time.

This facilitates timely decision-making and enables proactive response to any potential issues or alarms.

SoniCloud can generate alarms and notifications when temperature or environmental conditions fall or rise beyond the acceptable range. These alerts can be sent via email, SMS, or mobile app notifications to relevant personnel, enabling them to take immediate corrective actions to prevent product damage or spoilage.

Wireless monitoring systems come complete with data logging capabilities, allowing for easy retrieval and analysis. Historical data can be used for trend analysis, compliance reporting, and audits.

Reports can be generated automatically, simplifying regulatory compliance and quality assurance processes.

Sonicu streamlines regulatory compliance from private and government agencies including:

- The Joint Commission

- Food and Drug Administration (FDA)

- Centers for Disease Control and Prevention (CDC)

- Vaccine for Children (VFC)

- State Boards of Pharmacy and local boards of health.

With Sonicu's advanced technology, businesses can effortlessly track and manage temperature conditions in real-time, ensuring optimal product safety and quality across their operations.Sonicu's wireless monitoring systems are highly scalable and adaptable to different environments and needs.

Additional Sonicu's sensors can be easily added or relocated as the requirements change without the need for extensive wiring or infrastructure modifications. This scalability and flexibility make wireless systems suitable for a range of pharmaceutical settings, from small pharmacies to large manufacturing facilities.

Sonicu's wireless sensors have long battery life, which reduces the need for frequent battery replacements and minimizes downtime.

The sensors can be easily maintained and calibrated to ensure accurate measurements and reliable performance.

You can learn more about how our software helps compliance professionals in these case studies:

Problem: Too many false alarms on cryo monitoring lead to ignoring an alarm

Solution: Smart alarms that don’t produce alert fatigue

Problem: Cumbersome and costly legacy monitoring with difficult customer service

Solution: Simple and affordable solution with third-party sensor capabilities to drive down costs

Hamilton County Health Department: Vaccine Protection and Compliance.

Problem: Data loggers that lacked remote viewing capabilities and compliance automation

Solution: Remote viewing capabilities for weekend peace of mind and simple compliance

SNAP Calibration: Done for You NIST Calibration Service

Overall, Sonicu's wireless monitoring for pharmaceutical solutions offer a comprehensive solution to meet the temperature and environmental monitoring needs across the pharmacy.

Our sensors provide:

- real-time data

- remote accessibility and unlimited users

- alarms and alerts

- data logging

- connectivity flexibility; Wi-Fi, Cellular or Data Hub

- ease of maintenance.

This helps to safeguard the quality and efficacy of pharmaceutical products and ensures compliance with regulatory requirements.

If you care about receiving safe medicines from the pharmacist, safe vaccines from your doctor, and safe food from your grocery store, you care about temperature and conditions monitoring.

Case Study:

Katherine Shaw Bethea Hospital: installed dozens of pharmacy temperature monitoring solutions.

What are the main components of Sonicu's wireless pharmaceutical monitoring system?

Sonicu's wireless monitoring systems for pharmacies typically consist of several key components that work together to enable efficient and reliable monitoring of temperature and many other environmental conditions.

These components leverage various technologies to perform their functions.

- Wireless sensors are the primary components of the monitoring system. They are responsible for measuring and collecting data on parameters such as temperature, humidity, and air pressure differentials.

- Wireless sensors use communication protocols such as Wi-Fi, Bluetooth,, or cellular networks to transmit data wirelessly to SoniCloud, the central monitoring system.

- Wireless sensors use communication protocols such as Wi-Fi, Bluetooth,, or cellular networks to transmit data wirelessly to SoniCloud, the central monitoring system.

- The gateway acts as an intermediary between the wireless sensors and the central monitoring system. It receives the data transmitted by the sensors and transmits it to SoniCloud, where it is stored.

- SoniCloud is a cloud-based platform that receives, stores, and manages the data collected from the sensors. It provides the user interface for data visualization, analysis, and reporting.

- SoniCloud stores data securely and enables remote accessibility from any internet-connected device.

- Internet of Things (IoT) technologies facilitate the connectivity, data transmission, and integration of the wireless monitoring system components.

- The user interface allows authorized personnel to access and interact with SoniCloud.

- It can be a web-based interface, mobile application, or dedicated software.

- It can be a web-based interface, mobile application, or dedicated software.

- The alarms and alerting system is responsible for generating alarms and notifications when temperature or environmental conditions deviate from the defined thresholds.

- Alerting systems can utilize email or SMS gateways to send notifications to designated personnel.

- Mobile applications can send push notifications directly to users' devices to alert them of critical conditions.

What are the major pain points that Sonicu's wireless pharmaceutical monitoring systems address effectively?

Temperature excursions can occur during storage, transportation, or even within manufacturing facilities, potentially compromising the quality and efficacy of pharmaceutical products.

Sonicu's wireless pharmaceutical monitoring systems f provide real-time temperature monitoring, enabling immediate detection and alerting of any deviations from the defined temperature ranges.

This allows prompt corrective actions to be taken, such as adjusting storage conditions or removing affected products, reducing the risk of product damage or spoilage.

The pharmaceutical industry is subject to strict regulations and guidelines regarding temperature and environmental monitoring.

Sonicu's wireless monitoring systems help ensure compliance with these requirements by providing accurate and detailed data logging, audit trails, and automated reporting capabilities. This streamlines compliance processes and facilitates regulatory inspections.

Sonicu's wireless monitoring systems play a vital role in mitigating risks associated with temperature-sensitive pharmaceutical products.

By continuously monitoring and recording temperature and environmental conditions, these systems enable proactive identification of potential issues before they cause significant damage.

This helps ensure the quality and efficacy of pharmaceuticals, reducing the risk of product recalls, financial losses, and reputation damage.

Traditional monitoring systems often require manual data collection and time-consuming manual checks, leading to inefficiencies and increased labor costs.

Sonicu's wireless pharmaceutical monitoring systems automate data collection, provide real-time visibility into conditions, and generate automated alerts, reducing the need for manual interventions.

This improves operational efficiency, minimizes human errors, and optimizes resource allocation.

Sonicu offers remote access to real-time data, allowing authorized personnel to monitor temperature and environmental conditions from anywhere at any time.

This is particularly beneficial for multi-site operations or when monitoring systems are located in remote or hard-to-reach areas.

Centralized monitoring systems consolidate data from multiple locations, providing a comprehensive overview of the entire supply chain, enabling proactive decision-making and facilitating timely interventions when necessary.

Sonicu's wireless pharmaceutical monitoring solutions ensure the integrity of temperature and environmental data through automated and secure data capture.

SoniCloud stores historical data that can be analyzed for trend identification, process optimization, and quality improvement initiatives. Analytics and reporting capabilities provide valuable insights into operational performance, enabling data-driven decision-making and continuous improvement.

SoniCloud provides control 24/7:

- Unlimited users can view and control all monitored locations from a single dashboard

- Customized views to personalize time/data range based on your preferences

- Dashboard optimization for mobile devices with pinch-zoom and click functionality

- Easy drill-down and analysis of data

Check-out the benefits of implementing Sonicu's wireless monitoring system in your pharmacy.

- Wireless pharmaceutical monitoring provides real-time visibility into temperature and environmental conditions, allowing for immediate detection of deviations and timely intervention to prevent product damage or spoilage.

- Authorized personnel can access the monitoring system remotely via web-based or mobile applications, enabling monitoring and decision-making from anywhere, at any time.

- Automated data collection, reduce manual intervention, and automatic alerts and notifications when conditions go outside the acceptable range.

- This ensures prompt action and minimizes the risk of human errors or oversight.

- Sonicu's wireless systems are highly scalable and adaptable to different environments. Additional sensors can be easily added or relocated, making it suitable for businesses of various sizes and changing operational needs.

- With our cloud-based platform, SoniCloud, data is stored and archived , allowing for historical analysis, trend identification, and compliance reporting.

- This supports quality management, regulatory compliance, and continuous improvement initiatives.

- Reduce labor costs associated with manual data collection and checks and prevent costly product losses due to temperature excursions or compromised quality.

"Revolutionizing Pharmaceutical Supply Chains: Embracing the Power of Wireless Monitoring"

Wireless pharmaceutical monitoring addresses critical pain points across the supply chain, ensuring the integrity of pharmaceutical products and improving operational efficiency.

Sonicu's wireless monitoring solutions offer real-time monitoring, remote accessibility, automation, and scalability, enabling organizations to proactively manage temperature and environmental conditions.

By leveraging advanced technologies such as wireless sensors, cloud computing, and IoT, these systems provide accurate data, generate alerts, and streamline compliance and reporting processes.

The highlights of wireless monitoring include real-time visibility, remote accessibility, automation, scalability, data logging, and potential cost savings.

These advantages help mitigate risks, enhance product quality, ensure regulatory compliance, and optimize operational performance.

By implementing Sonicu's wireless monitoring systems, organizations can make data-driven decisions, reduce human errors, and prevent costly product losses.

To access these benefits and elevate your pharmaceutical operations, consider implementing Sonicu's wireless monitoring systems .

By embracing wireless monitoring, you can gain real-time insights, remotely monitor critical conditions, and enhance the overall quality and efficiency of your pharmaceutical supply chain.

Take the leap and embrace wireless monitoring for pharmaceutical solutions today to unlock the full potential of proactive monitoring, real-time data access, and streamlined compliance in your pharmaceutical operations.

American-based Customer Support: Robust & Reliable High Touch Service

Experience Unparalleled Service with Sonicu's Dedicated Team

At Sonicu, we understand that the true value of software and technology lies in the people who stand behind them.

Our probes and sensors are purposefully designed to withstand the harshest frozen environments, working tirelessly to collect and transmit billions of bits of data every month.

We recognize that even with the most advanced technology, occasional hiccups can occur, whether it's on the hardware or software side. But rest assured, our commitment to you is unwavering.

That's why we take pride in our team of dedicated American-based customer success managers, always ready to assist you with any service issues. With Sonicu, help is just a phone call away, ensuring a seamless experience for our valued customers.

Our customers are highly educated and protect highly valuable assets with our solutions. We boast more than 95 percent customer retention thanks to our reliable hardware, intuitive software and robust customer support.

At Sonicu, we prioritize customer satisfaction and swiftly address any support request that comes our way. Our responsive team is dedicated to resolving issues promptly and getting our customers back online without delay.

We are committed to fielding every customer service request promptly and getting our customers online rapidly.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

How IU Health

consolidated all of its pharmacy monitoring needs

into one cloud-based platform serving dozen of locations.