Air Pressure Monitoring for Environmental and Employee Safety

If you’re looking for a cloud-based air pressure monitoring solution that eliminates manual logging, improves compliance readiness and protects the environment and your employees, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts to protect asset

- Compliance: Automated reports

- Efficiency: Reduced Manual Logging

And what makes us different?

- Lifetime Warranty: Never buy hardware again!

- Unlimited Users: Scale across your entire org

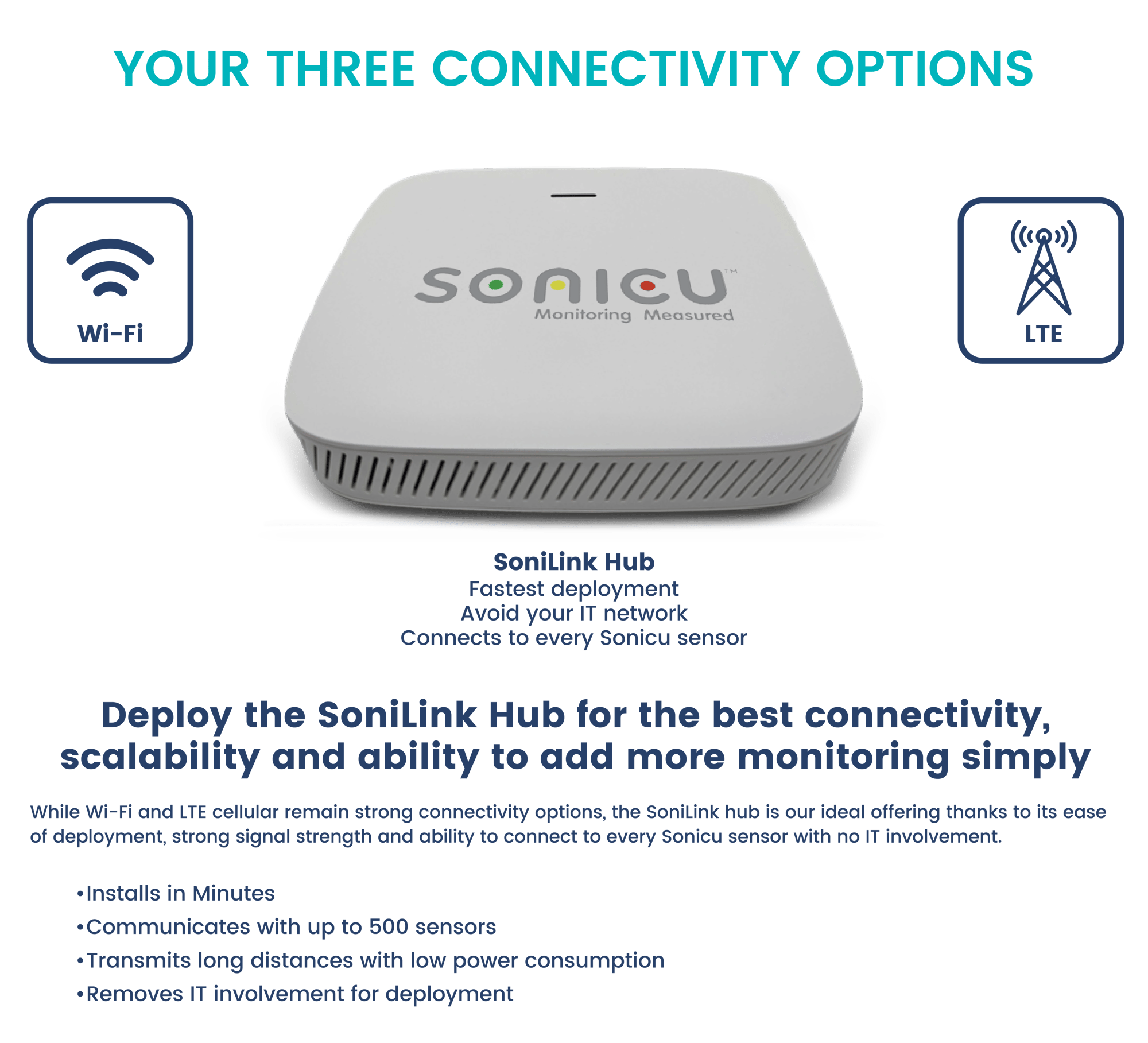

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

- Mobile App: 500 Freezers in your pocket

All American made and supported!

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

- Operational Efficiency: Virtually eliminate the need for tedious and costly manual logging

- Compliance Automation: Respond to virtually any regulatory audit or inspection in a few clicks with our reports section

- Asset Protection: Detect and respond to any temperature excursion that can threaten virtually anything perishable: food, drugs, vaccines, research, etc.

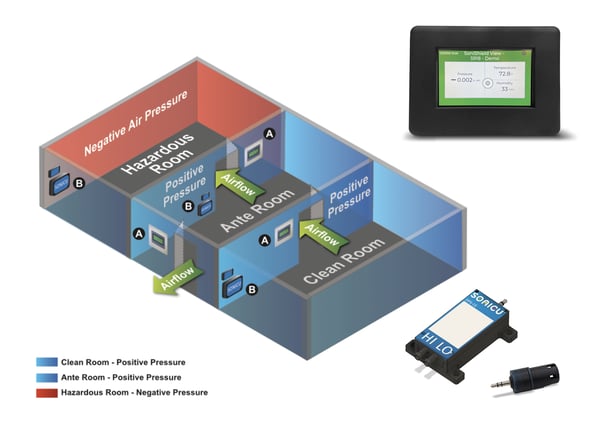

Differential Air Pressure Monitoring for Environmental and Employee Safety

Sonicu Technology Monitors Air Pressure and Alerts Staff

Companies concerned about the health and well-being of their employees, as well the environment, shudder at the thought of lead-laden dust emissions.

Emissions of any type can be cringe-worthy for business – and detrimental to safety.

That’s why monitoring differential air pressure in manufacturing environments is essential and in many cases a regulatory requirement.

Keeping Staff Safe & Regulators at Bay with Intuitive Environmental Monitoring

Air pressure differential is defined as “the weight of air molecules with cool molecules being heavier and denser than warm air molecules.”

A differential pressure monitoring system plays an instrumental role in protecting employee safety.

Along with employee safety, remote wireless monitoring benefits also include reducing manual readings and logging. Instead, digital data is updated in real-time and stored indefinitely to power alerts and reports.

Also, wireless differential air pressure monitoring is less expensive to install and service and more convenient than conventional digital pressure transmitters that require electrical wiring.

Alerting staff of any issues via phone call, text or email, empowering advanced maintenance and downtime and keeping your people out of harm’s way are the most immediate benefits of a wireless monitoring system.

Affordable and Reliable: Air Pressure Differential Monitoring

Affordable and Reliable: Air Pressure Differential Monitoring

Sonicu has real-world application of differential air pressure monitoring for abatement by serving Exide Technologies, a global leader in battery technology. The California company turned to Sonicu when they required a simple, mobile and dependable air pressure differential monitoring system.

Affordability was also a key buying decision and Sonicu is among the most affordable solutions for an advanced manufacturing facility when compared to similar cloud-based solutions.

Exide Technologies is far more than a battery supplier – the company also operates dozens of manufacturing plants, recycling plants and distribution centers nationwide.

You can read more about their success leveraging Sonicu’s air pressure differential monitoring solution here:

Access Exide Technologies: Air Pressure Differential for Construction case study here.

Such abatement work is conducted in air-tight enclosures requiring constant pressure differential monitoring.

Negative pressure must be maintained within the enclosure to ensure lead-containing dust is not emitted into the workplace and the environment.

For Exide, which recently introduced a new suite of Motion + Fleet Smart Tools designed to provide innovative digital and cloud-based solutions to manage forklift battery and charging stations, ensuring environmental safety is vital.

“Globalization is changing the world. Warehouse managers are faced with the challenge of constantly rethinking the efficiency of their business,” Exide says. “To do this, they need flexible intralogistics solutions at the highest level to solve tomorrow’s tasks today.”

Air Pressure Differential Reporting in Real-time

Sonicu’s SoniCloud solution is a scalable, digital sensor-driven monitoring platform that automatically documents when desired room differential air pressure is achieved and maintained, ensuring regulatory compliance.

The data is stored indefinitely in the Amazon Web Services cloud platform and is easily accessible via virtually any web browser or the mobile app.

The SoniCloud platform monitors temperature sensitive products – like Exide’s batteries – critical room conditions and equipment status on a real-time basis.

This digital wireless technology and cloud-based software platform fully automates 24/7 remote monitoring, alarming and reporting for industrial applications.

This two-minute video shows how SoniCloud works.

Exide’s need for digital air pressure monitoring and alerting is required in its industry.

Sonicu’s technology also helps mitigate risk and prevent unsafe working conditions from HVAC system failure or power outage.

The system quickly responds to alerts, analyzes data and performance, and creates reports from a digital dashboard.

Their system utilizes Sonicu Reporting Tools that offer advanced reporting capability to eliminate manual processes and compliance automation, so:

- Regulatory-compliant reports are auto-generated

- Fully automated data logging and reporting solution

- Unlimited data storage has 99 percent uptime

- Flexible, administrative rights ensure the right information is accessed by the right people

Summary views are key for tracking emissions and air quality by providing graphical views of all monitoring points to improve situational awareness.

This makes it easy for Exide employees and safety staff to understand overall monitoring performance and identify problems through:

- Flexible charting for report generation

- Alarm Summary highlighted in red

- Hot-links to detailed views and reports

Filtered views offer high-level view weekly summaries for every deployed wireless monitoring device, including:

- Number of alarm events by device

- Minimum, maximum and average readings

- Valuable report for location managers and staff

Sonicu’s reporting detailed views provide fully automated temperature logs to eliminate manual processes, and are regulatory compliant for reporting. They also include:

- Daily minimum and maximum temperatures

- Real-time temperature data by day and hour

- Visualize performance over time to spot problems

Safety First: Air Pressure Differential for Advanced Manufacturing

Sonicu’s reporting platform is important for safety on many levels.

Along with citations for workplace safety violations, unsafe working conditions from harmful emissions are dangerous to workers’ health, especially in industrial settings.

According to the Occupational Safety and Health Administration (OSHA), federal law entitles employees to a safe workplace.

“Your employer must keep your workplace free of known health and safety hazards. You have the right to speak up about hazards without fear of retaliation,” OSHA reports.

OSHA's mission is to "assure safe and healthy working conditions for working men and women by setting and enforcing standards and by providing training, outreach, education, and assistance."

This regulatory agency of the United States Department of Labor originally had federal visitorial powers to inspect and examine workplaces.

President Richard M. Nixon signed the Occupational Safety and Health Act OSH Act in 1970, marking a massive shift in the federal government’s oversight in protecting workers from potentially unsafe conditions. .

OSHA says its workplace safety inspections are shown to reduce injury rates and injury costs without adverse effects on employment, sales, credit ratings, or firm survival.

OSHA has jurisdiction over approximately 7 million worksites, focusing inspection resources on the most hazardous workplaces in the following order of priority:

- Imminent danger situations — hazards that could cause death or serious physical harm receive top priority.

Compliance officers will ask employers to correct these hazards immediately or remove endangered employees. - Severe injuries and illnesses — employers must report all work-related fatalities within 8 hours.

All work-related inpatient hospitalizations, amputations, or losses of an eye within 24 hours. - Worker Complaints — allegations of hazards or violations also receive a high priority. Employees may request anonymity when they file complaints.

- Referrals of hazards from other federal, state or local agencies, individuals, organizations or the media receive consideration for inspection.

- Targeted inspections — inspections aimed at specific high-hazard industries or individual workplaces that have experienced high rates of injuries and illnesses also receive priority.

- Follow-up inspections — checks for abatement of violations cited during previous inspections are also conducted by the agency in certain circumstances.

Learn more about OSHA in this Fact Sheet.

Per OSHA, workers also have the right to:

- Receive workplace safety and health training in a language you understand

- Work on machines that are safe

- Receive required safety equipment, such as gloves or a harness and lifeline

- Be protected from toxic chemicals

- Request an OSHA inspection, and speak to the inspector

- Report an injury or illness, and get copies of your medical records

- Review records of work-related injuries and illnesses

- See results of tests taken to find workplace hazards

OSHA promotes standards addressing air quality in indoor work environments, especially for workers that face a “significant risk of material impairment to their health due to poor indoor air quality.”

By providing differential air pressure monitoring solutions, Exide is able to ensure optimal indoor air quality compliance and implementation.

Sonicu helps Exide implement controls that meet OSHA’s protocols for safety that include specific contaminants and their sources such as:

- Outdoor air contaminants

- Microbial contamination

- Maintenance and cleaning chemicals

- Pesticides

- And other hazardous chemicals within indoor work environments

Ensuring workers’ safety is one of three primary reasons companies like Exide look to Sonicu for cloud-based differential air pressure sensor systems to eliminate manual logging, improve compliance readiness and protect temperature sensitive assets.

Sonicu provides:

- Compliance automation: Respond to virtually any regulatory audit or inspection in a few clicks with our reports section

- Operational efficiency: Virtually eliminate the need for tedious and costly manual logging

- Asset protection: Detect and respond to any temperature excursion that can threaten virtually anything perishable: food, drugs, vaccines, research, etc.

The Sonicu Data Concentrator equips facility managers to simply and affordably connect air pressure differential monitors from across an entire enterprise to their existing Building Automation (Management) System.

This means that temperature and environmental data collected and stored on SoniCloud can be shared wirelessly and affordably across an entire enterprise, allowing remote-based facility leaders to have real-time access to environmental conditions that locally based department managers have.

“The Sonicu Data Concentrator can be a game changer for complex and dynamic manufacturing or processing facilities that want to enjoy the flexibility and cost-savings of a wireless monitoring solution with the robust reporting and high-level management capabilities of a Building Management System,” said Bryan Mitchell, VP, Marketing and Business Development.

“And if your facility is already leveraging a Schneider EBO platform, the Sonicu monitoring solution connects seamlessly without any additional software to boost your visibility, safety and compliance with a solution that installs in minutes and requires less than an hour configure.”

You can learn more about how our software helps compliance professionals in these case studies:

Problem: Dining department struck with regulatory violations

Solution: Enterprise-wide monitoring that automates regulatory compliance across all departments

Problem: Release of lead particles in battery projects

Solution: Mobile, affordable air pressure monitoring solution

Problem: Burdensome, labor-intensive legacy temperature monitoring

Solution: Remote, wireless autonomous monitoring to drive down manual processes

Heat Stress Monitoring and Safety with the Leader in Wireless Monitoring

Sonicu collaborates with Exide to provide a systematic approach to finding and fixing hazards regarding Environmental Health and Safety (EHS).

Sonicu’s differential air pressure monitoring system’s innovation helps workers better perform in their EHS-related job role, which demonstrates Exide’s commitment to workplace health and safety.

“A fundamental part of Exide’s mission is an unwavering commitment to workplace safety and this is a core value of our company as well,” said Ed Osborne, Exide Technologies Vice President, Environmental Health and Safety.

Osborne said Exide views EHS as a “responsibility to operate in a manner that protects the health, safety and well-being of employees, contractors, visitors, and those in the communities where they live and operate.”

“That responsibility starts with each of our employees understanding their role in maintaining a safe and healthy workplace,” he said.

Best Environmental Monitoring for Manufacturing

Sonic’s heat index temperature monitoring delivers a solution for rising temperatures attributed to climate change that create a significant risk to rising heat injury risk in the workplace.

Companies are experiencing increased concern over heat stress effects on indoor workers in industrial settings.

The Bureau of Labor Statistics (BLS) reports that from 2011 to 2019, more than 30,000 workers suffered illness or injury due to extreme heat exposure.

“Today’s heat waves are just another indication of how extreme heat due to the climate crisis is endangering workers,” said Robert Weissman, president of Public Citizen.

Continued exposure to high temperatures in occupational settings places employees at great risk of heat stress.

Over time, heat exhaustion, heat stroke, heat cramps and similar health challenges may arise, says the Centers for Disease Control and Prevention (CDC).

According to the CDC, new workers should not be incrementally exposed to hot conditions over a one to two-week period or longer.

Slowly adjusting to a hot environment helps employees adapt physiologically, including increased sweat production and decreased electrolyte loss during sweating.

The CDC further warns that new workers should not have more than a 20 percent exposure on day 1 and an increase of no more than 20 percent on each additional day.

“For workers who have had previous experience with the job, the acclimatization regimen should be no more than a 50 percent exposure on day 1, 60 percent on day 2, 80 percent on day 3, and 100 percent on day 4,” said the CDC, Heat Stress Acclimatization.

The CDC defines acclimatization as the “beneficial physiological adaptations that occur during repeated exposure to a hot environment.”

Per the CDC, these physiological adaptations include:

- Increased sweating efficiency (earlier onset of sweating, greater sweat production, and reduced electrolyte loss in sweat)

- Stabilization of the circulation

- The ability to perform work with lower core temperature and heart rate

- Increased skin blood flow at a given core temperature

Monitoring and training encourages employers to educate workers on heat safety, helping them acclimate to specific hot conditions of the given work environment.

Supervisors may provide training on proper conduct acclimatization, procedures when employees show signs of heat stress, weather report monitoring, and the necessity for rest and hydration breaks.

Training for employees can focus on work environment acclimatization, especially helping them recognize signs and symptoms of heat illness or injury.

Also important with training is how employees can respond to situations arising from heat exposure, and handling any protective equipment.

You can learn more about how our software helps compliance professionals in these case studies:

Problem: Needed to reduce time to complete HACCP compliance reports

Solution: Self-install of temperature monitoring for compliance automation

Problem: Needed pharmacy temperature monitoring following refrigerator loss across many remote clinics:

Solution: Simple Sonicu installation and configuration simplified standing-up remote systems

Indiana University Health: Enterprise Hospital For Temp, Humidity, Air Pressure

Problem: Server Based Monitoring lacking Enterprise Visibility

Solution: One Window into all monitoring across dozens of facilities

Proactive Protection: Heat Stress Monitoring for Warehouses and Manufacturing

How do temperature and differential air pressure monitoring capabilities help keep employees safe?

By avoiding reactionary responses to heat stress issues, and poor air quality conditions, companies can provide proactive solutions to safeguard workers with safety protocols.

Regulations are issued in industrial settings to prevent workplace accidents, injuries, illness, or death, and are essential to keep businesses compliant.

Sonicu systems virtually eliminate dated manual processes to help staff make the best use of current technology and facilitate automated audit reports for compliance purposes.

Sonicu’s temperature monitoring solution actively assesses temperature conditions between -55˚ to +30˚C ensuring assets remain at ideal conditions 24/7.

Advanced alarms issue notifications based on established thresholds.

The SoniCloud monitoring system utilizes a proprietary platform that features free updates for both firmware and software.

These features make heat stress monitoring and differential air pressure monitoring a priority for environmental and employee safety.

Enhancing safety prevents injury and illness, and helps develop internal frameworks to best manage temperatures in working spaces.

This technology helps allocate resources to crucial systems such as temperature and differential air pressure monitoring equipment for a safer working environment.

Cost competitiveness, great customer service, great control over the monitoring system, and low maintenance. You can't beat that.

Sonicu costs are considerably more reasonable than our historic system, as well as other competitors on the market. The equipment is robust but simple to learn and utilize.

Having safe and secure storage provides reassurance that any future family building efforts will be protected. Sonicu gave us the ability to more easily put our head on the pillows and sleep easier at night knowing we had invested in a strong monitoring system.”

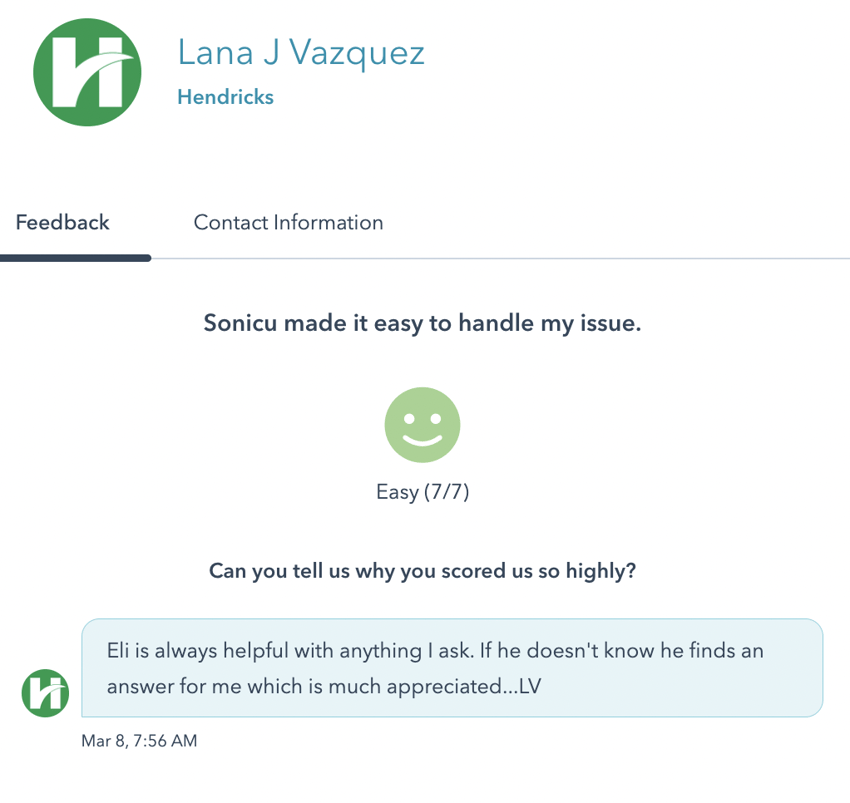

American-based Customer Support: Robust & Reliable High Touch Service

Software and technology is only as good as the people who stand behind it.

At Sonicu, that means our team of American-based customer success managers who are never more than a phone call away to help field and fix any service issues.

Our probes and sensors are placed in demanding frozen environments and our software literally sends billions bits of data monthly, meaning there’s always the potential for a hiccup on either the hardware or software.

We are committed to fielding every customer service request promptly and addressing our customer’s concerns promptly and professionally.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

Before Sonicu, we had to don bunny suits to check the status of our cleanrooms. Now we check our phones and know right away. The system saves us time and effort and helps us respond to environmental