Air Pressure Monitoring for Manufacturing

If you’re looking for a cloud-based life sciences air pressure differential monitoring system that helps your team eliminate manual logging, improve compliance readiness and protect all your temperature sensitive assets, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts via text, email, push notifications and phone calls to protect your precious assets

- Compliance: Automated compliance reports

- Efficiency: Reduced Manual Logging and time spent on reports

And what makes us different?

- Lifetime Warranty: Never buy hardware again!

- Unlimited Users: Scale across your entire organization

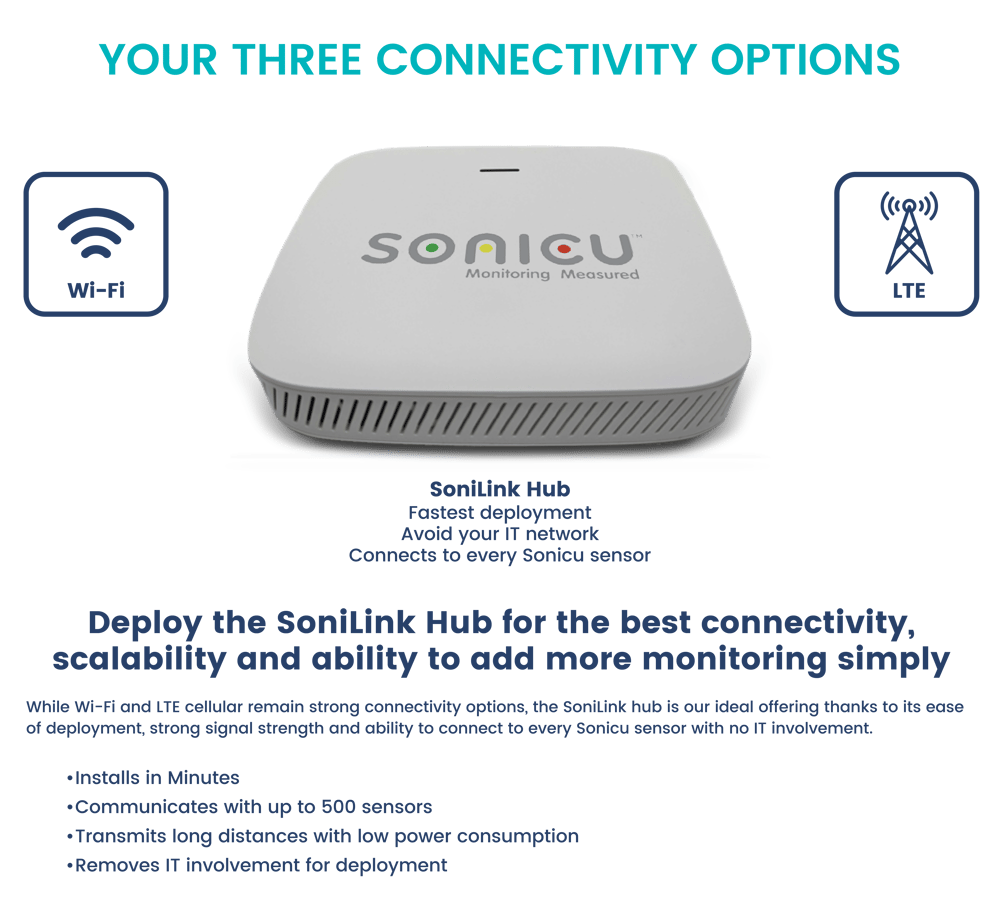

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

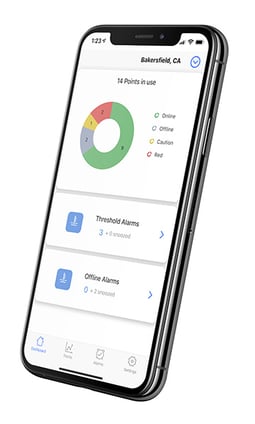

- Mobile App: 500 Freezers in your pocket

- Facility monitoring: Simple to add water leak, door open, occupancy, and even IAQ monitoring

Engineered in Indiana with U.S.-based support.

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

Air Pressure Monitoring for Manufacturing

If you’re looking for a cloud-based life sciences air pressure differential monitoring system that helps your team eliminate manual logging, improve compliance readiness and protect all your temperature sensitive assets, you’ve arrived at the right place.

Some of the finest names in healthcare, including Indiana University Health, University of Michigan Health System and Stanford University, rely on Sonicu to provide robust continuous temperature monitoring for their cold and frozen environments.

These respected brands turn to Sonicu for three primary reasons:

- Operational Efficiency: Virtually eliminate the need for tedious and costly manual logging

- Compliance Automation: Respond to virtually any regulatory audit or inspection in a few clicks with our reports section

- Asset Protection: Detect and respond to any temperature excursion that can threaten virtually anything perishable: food, drugs, vaccines, research, etc.

When you combine these three significant feature benefits, our clients average about $80,000 of savings for every 100 hospital beds.

At research or university locations without beds, it’s not hard to imagine the time savings alone by simply not having staff manually record temperatures several times per day.

Our customers stay with us thanks to our American-based customer support that is never more than a phone call away.

While our technology is intuitive and powerful, we know it’s only as strong as the people who stand behind it.

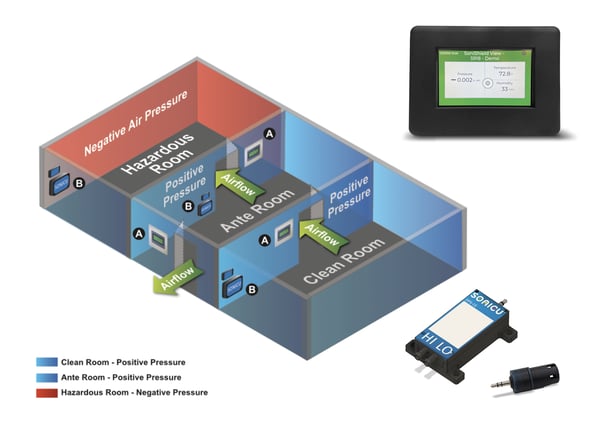

Many facilities have sensitive areas and environments in which air pressure differential is essential to quality control.

Advanced manufacturing facilities - including automotive, aviation and electronics - are often equipped with clean rooms similar to hospitals to protect highly sensitive components.

Regulatory agencies require many facilities to maintain records of temperature, humidity and other settings throughout the facilities.

Having accurate records on top of running a company reduces staff resources and reduces staff stress as manual monitoring is error-prone.

Today, many facilities rely heavily on manual processes to maintain records and ensure compliance. Data loggers are prevalent but still require someone to visit each facility to record data every day.

Loggers assist with compliance but rarely identify problems until it’s too late. That’s where real-time continuous monitoring can help organizations improve operations and drive facility improvement.

You can learn more about how our software helps compliance professionals in these case studies:

Discount Drug Mart: Power Outage Protection + Compliance Automation

Problem: Transitioning from manual temperature logs and reactive power outage management

Solution: Adopting Sonicu's advanced system for seamless temperature monitoring and real-time power outage alerts across its 77 locations.

Hendricks Health: From Nutrition to the OR

Problem: The need to improve compliance and safety across various departments, starting from nutrition to the operating rooms.

Solution: Upgraded monitoring systems to enhance patient safety and streamline compliance across multiple facilities, including local YMCA rehabilitation facilities.

IU Health: Enterprise Monitoring

Problem: Challenges of using a locally based server and multiple monitoring solutions across departments.

Solution: Transitioned to a single, cloud-based solution with Sonicu to enhance monitoring capabilities across more than a dozen locations and the IU School of Medicine.

Best Air Pressure Monitoring for Manufacturers

Modern HVAC systems use a combination of relief dampers, exhaust fans, air intakes, and other mechanical methods to adjust air pressure inside and within certain portions of a facility. These combined components create positive or negative pressure that create air pressure differential.

All components that make up a modern HVAC system are monitoring devices called differential switches. These devices act as sensors by measuring pressure and flow rates through lines and into rooms to ensure all operations are efficient.

With an adequate pressure monitoring system, important things such as air volume, channel pressure, filter conditions, and air pressure can easily be monitored.

One method for air pressure differential monitoring for manufacturers is through a balanced utilization of real-time BAS data monitoring with a connected high-precision data logger.

There are various ways and methods of monitoring air pressure differential that include traditional data loggers connected by Ethernet and wireless data loggers with cellular or Bluetooth connectivity.

In manufacturing facilities, an Ethernet or Wi-Fi-connected data logger is the best choice due to its affordability and reliability.

A mobile application support strengthens these options as it allows for a 24/7 monitoring solution.

Air pressure differential monitoring tools for manufacturing that combine all of these crucial factors are the most helpful for companies all over the world.

Sonicu’s cloud is the ideal monitoring tool for every company in need of automating monitoring processes across all departments thanks to its dependability, affordability and simplicty.

With 24/7/365 continuous monitoring we help you:

- Protect Valuable Assets with instantaneous, customizable, and actionable alerts sent via phone, email, text or pager.

- Improve Operational Efficiency by eliminating manual monitoring and paper logs

- Adhere to Regulatory and Compliance requirements by providing unlimited data storage, timely reporting and NIST management.

Air Pressure Monitoring in Advanced Manufacturing

Slight changes in air pressure differential monitoring can severely impact an employee's health and well-being.

Accurate and continuous monitoring in a work environment is essential.

Unlike traditional manual monitors, wireless monitors provide continuous monitoring that does not require manual readings and recording or electric wiring.

Along with continuous monitoring, modern air pressure differential monitoring systems can alert staff of any issues via phone call, text or email.

This minimizes downtime and prevents workplace incidents and injuries.

With personalized user-defined alerts and an alarm system, the Sonicu program will notify all set users immediately to prevent conditions from becoming hazardous.

The system also allows Multi-Site access by users or restricts user access to a single site or zone.

The Sonicu system will help your team stay compliant with

- Joint Commission

- VFC

- CDC

- USP,

- FDA

- And other state and federal regulatory agencies.

Our platform provides 24/7/365 monitoring at desired intervals.

Each probe comes with a NIST certificate of traceability and is ISO 17025-compliant.

The Sonicu calibration program easily and cost-effectively helps you maintain compliance.

As a wireless tool of differential pressure monitoring, the platform can be utilized across many industries ranging from hospitals to restaurants to manufacturing warehouses.

The tool monitors filtered conditions in rooms to ensure there is positive-pressure overall, proper exhaust pressure, and many other conditions that are needed to ensure safety and compliance.

Best Air Pressure Monitoring for Manufacturing Sensor

According to a case study with a lab at Ohio University, an average of 40 hours monthly was saved in manual temperature logging and air pressure differential monitoring.

When searching for a partner, the university sought a temperature and environmental monitoring provider that could help reduce simple maintenance issues such as software hiccups such as:

- Too many security questions for each new log-in

- Changing batteries on sensors and probes too often

- And affordability concerns

They also searched for a monitoring provider that could perform annual probe and meter calibration.

The SNAP program from Sonicu mails pre-calibrated probes and sensors to customers for easy snap-in replacement and calibration or professional installation was the perfect solution to their problem.

Ohio University said: “The Sonicu system provided an easier, faster solution, compared to existing systems like radio wave transmission signals. Now the cloud-based system is available, and the signal is faster and way easier to maneuver and control.”

Room temperature and air pressure differential monitoring for manufacturing are important as it ensures that all rooms are protected from bacteria, viruses, and other materials used in the lab or clean room.

With Sonicu being so affordable and convenient, both of these diverse conditions can be easily monitored with one simple software system.

“You don't have to be in the lab, and you don't have to log into your computers. It’s just in my pocket,” the lab director explained.

“When the Sonicu system notifies you, you can address the issue immediately. It’s just convenient, and time-saving, and you can prevent large potential damage. That's obviously valuable.”

Conclusion

In conclusion, Sonicu is the place to go for air pressure differential monitoring for manufacturing and asset protection.

Sonicu ensures accurate records that eliminate the risks of errors from manual logging.

The system meets all compliance standards and regulatory agency requirements while also being affordable. Scores of manufacturing, healthcare and distribution companies turn to Sonicu for its affordability and robust customer service.

When using the system, facilities report saving dozens of hours of manual logging and compliance report drafting time.

Through a mobile app with personalized settings and alerts when there’s a problem, Sonicu ensures complete convenience right from your pockets.

That means you’re connected to your critical and sensitive environments from anywhere at any time.

Learn more about how Sonicu providers exemplary service for its customers in these case studies:

Sonicu has more than 500 customers in all 50 states and serves Healthcare, Health Sciences, Pharmaceutical and food service industries. Customers trust Sonicu to monitor cold storage temperature, ambient room condition temperature and humidity, air pressure differential and noise.

We deliver safety, compliance and efficiency. Simply.

If you care about receiving safe medicines from the pharmacist, safe vaccines from your doctor and safe food from your grocer, you care about temperature and conditions monitoring.

Our customers save on average about $80,000 per 100 beds while streamlining regulatory compliance from private and government agencies including the Joint Commission, FDA, CDC, VFC, State Boards of Pharmacy and local boards of health.

Indiana University Health: Enterprise Hospital For Temp, Humidity, Air Pressure

Problem: Server Based Monitoring lacking Enterprise Visibility

Solution: One Window into all monitoring across dozens of facilities

Cryopoint: Ultra Low Cold Storage, Research, Lab

Problem: Too many hours spent on manual logging and calibration

Solution: Reduced Manual Logging and Done For You Calibration

Problem: Pharmacy Suffered Too Much Humidity In New Wing, impacting Compounding Pharmacy

Solution: Affordable Humidity Monitoring that Delivered POwerful data to prompt contractors to fix improperly sized air handler

Problem: Dining department struck with regulatory violations

Solution: Enterprise wide monitoring that automates regulatory compliance across all departments

Problem: Release of lead particles in battery projects

Solution: Mobile, affordable air pressure monitoring solution

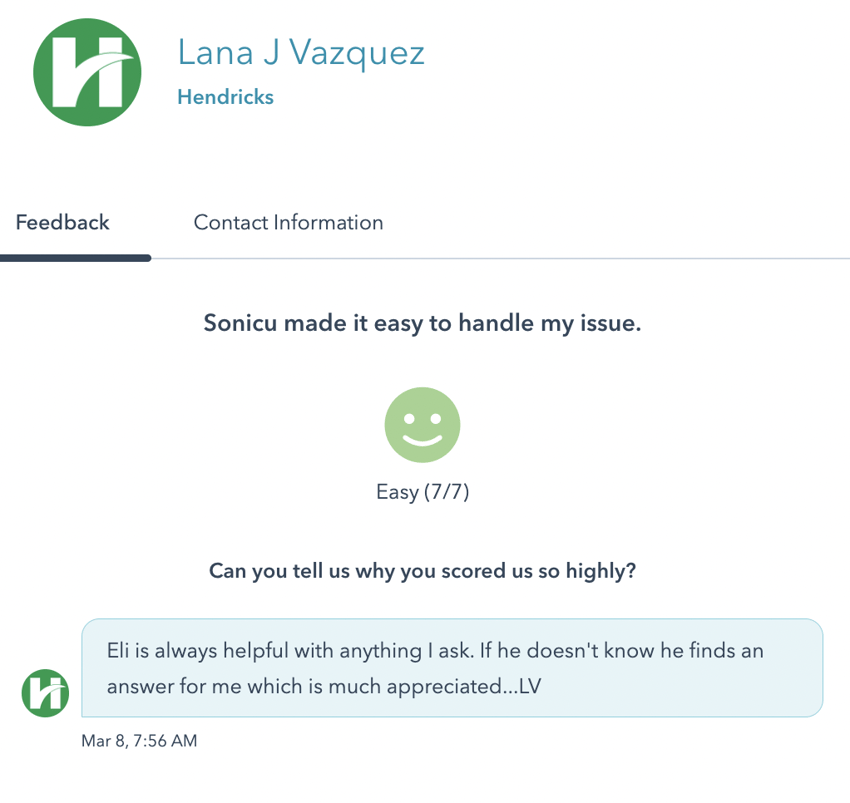

American-based Customer Support: Robust & Reliable High Touch Service

Software and technology is only as good as the people who stand behind it.

At Sonicu, that means our team of American-based customer success managers who are never more than a phone call away to help field and fix any service issues.

Our probes and sensors are placed in demanding frozen environments and our software literally sends billions bits of data monthly, meaning there’s always the potential for a hiccup on either the hardware or software.

We are committed to fielding every customer service request promptly and addressing our customer’s concerns promptly and professionally.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

How IU Health

consolidated all of its pharmacy monitoring needs

into one cloud-based platform serving dozen of locations.