Laundry Infection Control Air Pressure Differential Monitoring

If you’re looking for a cloud-based air pressure monitoring sensor solution that eliminates manual logging, improves compliance readiness and enhances healthcare laundry infection control through valuable air pressure differential monitoring, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts via text, email, push notifications and phone calls to protect your precious assets

- Compliance: Automated compliance reports

- Efficiency: Reduced Manual Logging and time spent on reports

And what makes us different?

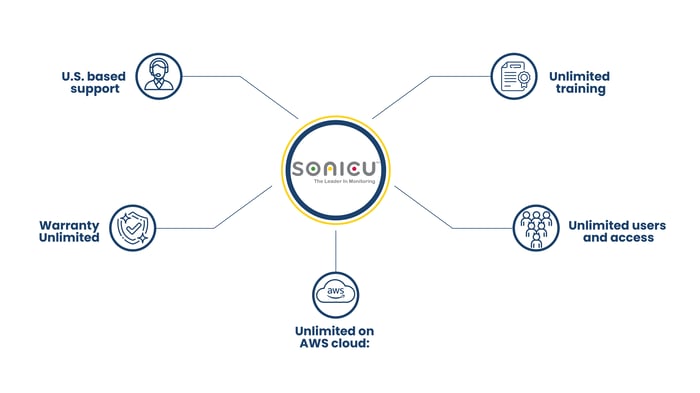

- Lifetime Warranty: Never buy hardware again!

- Unlimited Users: Scale across your entire organization

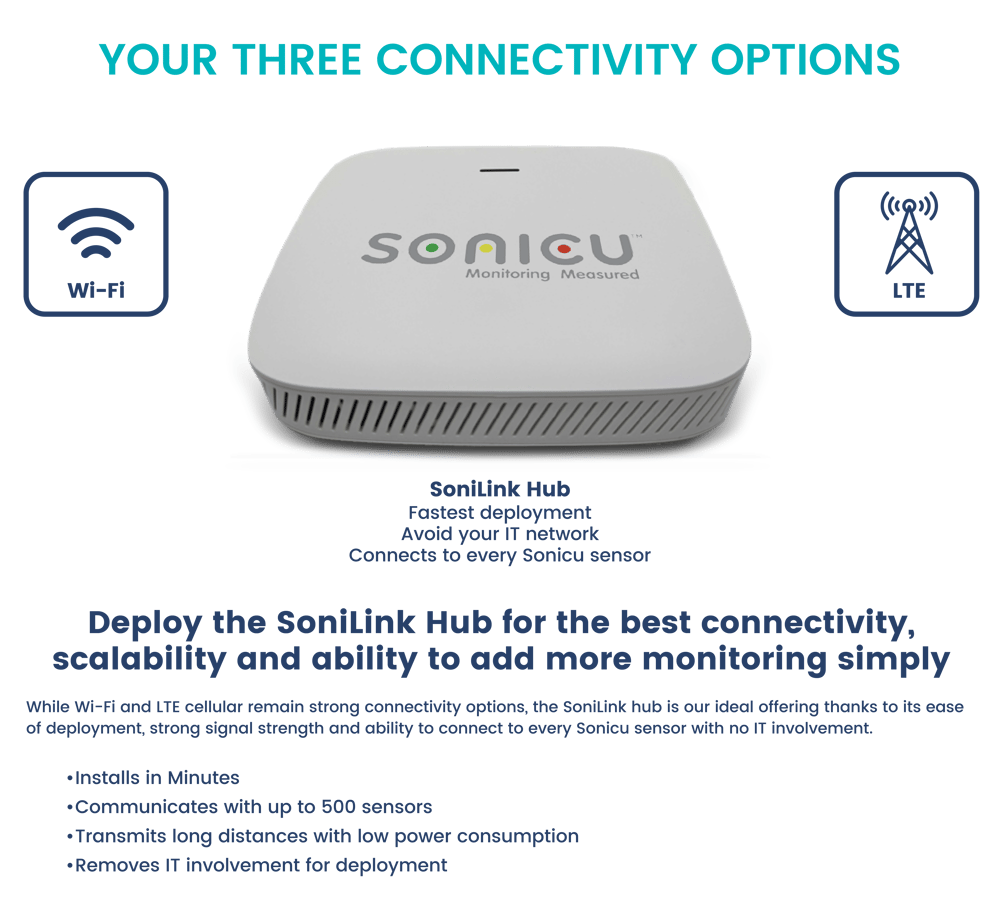

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

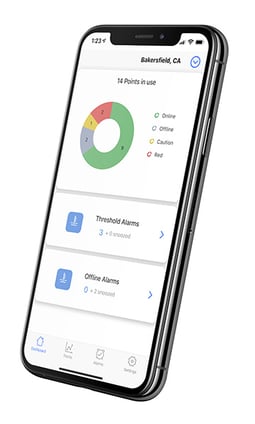

- Mobile App: 500 Freezers in your pocket

- Facility monitoring: Simple to add water leak, door open, occupancy, and even IAQ monitoring

Engineered in Indiana with U.S.-based support.

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

The Importance of Air Pressure Monitoring in a Healthcare Laundry Setting

With the laundering of clothes at healthcare facilities, it is possible to spread infectious matter.

While it may not seem as immediately obvious as controlling airflow in an operating room or compounding pharmacy, there is a role to play for infection control professionals in managing the risk from laundry facilities.

Facilities should strive to adhere to all regulatory agency guidelines by ensuring strong operational protocols are in place, including pressure monitoring in a laundry facility.

These protocols include the following:

- adequate laundry areas with proper air pressure monitoring

- proper laundry chute maintenance

- sorting areas & removal procedures

- post-wash infection prevention procedures.

One of the most important of these protocols is air pressure monitoring.

If there is an issue with air pressure, such as negative air pressure in the clean linen area or the latter with the dirty linen area, infections can spread both in and outside of the facilities.

This article will explore the threats associated with infection control in healthcare laundry facilities and show how simple and affordable pressure cloud-based pressure monitoring can play a part in decreasing hospital-acquired infections.

Importance of Adequate Laundry Areas and Operational Protocols

Laundry services for healthcare facilities are provided with three locational options:

- off-campus

- co-operatives

- and on-premise laundry

Laundry facilities are required by guidelines to have been constructed and operated in certain ways.

In regards to design, facilities must have two separate areas:

- a “” dirty area to receive and handle soiled laundry

- and a clean area for processing washed linens

To minimize the risk of re-contamination of cleaned laundry with aerosolized contaminated lint, receiving areas should practice protocols of laundry infection control through air pressure monitoring.

Air pressure in areas with soiled linens should be negative when compared to the opposing clean areas.

Contaminated textiles and fabrics are allowed to be transported by cart or chute.

With the use of chutes, there must be proper design, maintenance, and use that adheres to safety protocols.

By leveraging a remote wireless pressure monitoring system like Sonicu, infection control and facility management professionals enjoy an affordable and easy-to-deploy system trusted by some of the finest names in healthcare and life science.

Benefits of the Sonicu remote wireless monitoring system include:

- Asset Protection: Get alerts when a freezer is malfunctioning to protect assets like medicines, vaccines, blood, research, sperm/eggs

- Compliance Automation: Creates simple reports to satisfy local/state/federal regulations

- Operational Efficiency: Spend less time capturing data manually: Both temps/conditions and reporting

“We’re seeing a greater emphasis on air pressure differential monitoring throughout healthcare facilities following the lessons learned during the COVID-19 challenges,” said Bryan Mitchell, Vice President, Marketing, Sonicu. “From construction sites to laundry facilities, healthcare professionals are demanding a higher level of real-time and historical data to help them drive a culture of safety.”

ASHE continues to set the standards organizations look to, and include a long list of healthcare locations that require air pressure standardization.

According to ASHE, the following are examples of positively pressurized rooms:

- Operating rooms

- Delivery rooms

- Trauma rooms

- Newborn intensive care

- Laser eye rooms

- Protective environment rooms

- Pharmacy

- Laboratory, media transfer

- Central Medical and Surgical Supply Clean workrooms

- Central Medical and Surgical Supply Sterile Storage

Meanwhile, the following areas require negative pressure:

- ER waiting rooms

- Radiology waiting rooms

- Triage

- Toilet rooms

- Airborne infection isolation (AII) rooms

- Darkrooms

- Cytology, glass washing, histology, microbiology, nuclear medicine, pathology, and sterilizing laboratories

- Autopsy rooms

- Soiled workrooms or holding rooms

- Soiled or decontamination room for central medical and surgical supply

- Soiled linen and trash chute rooms

- Janitors’ closets

Laundry chutes that are not properly designed, used, and maintained increase the risk of propelling airborne microbial contaminants on both the linens and throughout the facilities.

Laundry chutes should also be maintained under negative air pressure to prevent the spread of dangerous microorganisms from floor to floor of the facilities.

Loose, contaminated pieces of laundry that increase the risk of laundry infection control should be closed or secured through both proper air pressure monitoring and the use of sealed bags and storage containers.

After the proper handling and cleansing of soiled laundry, healthcare facilities should have a point of sorting readily available.

Sorting after washing reduces the risk of exposure of laundry workers to infected materials in soiled fabrics, helps prevent potential injuries to personnel, and reduces airborne microbial contamination in the laundry area.

Sorting should occur before washing in order to protect both the fabrics and machinery from hard objects such as syringes, needles, and other unknown patients’ property.

You can learn more about how our software helps compliance professionals in these case studies:

Boy Scouts: Protecting Campers from a Temperamental Walk-in Cooler

Problem: An aging walk-in cooler failed at a remote campground in Ohio, causing significant food loss and logistical challenges for the Boy Scouts.

Solution: Sonicu provided a system that was easy to install, connected with a mobile app, affordable for a non-profit budget, and automated the required manual logging.

Hamilton County, Indiana Health Department: Vaccine Monitoring

Problem: The need to protect vaccines from temperature excursions and meet state compliance requirements with an outdated analog system.

Solution: Implemented a new monitoring system with a mobile app and robust support, enhancing the management of remote COVID-19 vaccination programs.

Katherine Shaw Bethea Hospital: Pharmacy Monitoring for Remote Clinics

Problem: After a freezer failure led to a loss of drugs, the pharmacy director needed a reliable and simple monitoring solution for multiple remote clinics.

Solution: Adopted Sonicu's temperature monitoring system, enhancing audit readiness and deploying a mobile app to employees across clinics in Illinois.

Proper Removal and Maintenance Protocols

With the dynamic challenges and volatile business of healthcare facilities, preventing hospital-associated infections is immensely difficult as there’s the risk of new strain of illness every day.

Hospitals present diverse types of specialized risks but a true risk is mishandled healthcare laundry.

Healthcare facilities often cleanse and reuse the same textiles between facilities.

Typical healthcare linens include towels, clothing, curtains, surgical drapes, reusable mop heads, and patient and staff bedding.

Hospital linens can harbor a significant mass of pathogenic organisms.

The most commonly isolated ones are gram-negative organisms such as Enterobacterales and Staphylococcus species. Seeing the risks for transmission of infection, there is a significant need for laundry infection control through proper procedures.

A strong procedure process includes three distinct sections:

- Removal;

- Cleaning;

- Storage.

When removing linens, there must be proper storage and safe transportation to the cleaning facilities.

Soiled linens pose a significant danger to healthcare staff and patients, who can be contaminated by staff.

All used linens, regardless of visible soiling, should be considered and handled as infectious. Used linens should not be shaken or disturbed in a way that could aerosolize infectious particles.

Air pressure monitoring from Sonicu can be a simple and affordable way to increase your organization’s focus on healthcare laundry safety.

Sonicu serves more than 600 customers nationwide and provides air press monitoring across a wide range of industries, indulging

- Healthcare: Nurses respond to our alerts to keep your medicine safe

- Life Science/Lab: Lab directors rely on our alerts to protect priceless research

- Universities: Research and science department heads

- Food Service: Food distributors rely on our technology to protect your dinner

Adequate cleaning and disinfection are essential when cleaning soiled linens. Previous CDC guidelines have strict guidelines for temperature and disinfection concentrations that ensured dangerous pathogens remained inactivated.

In order to prevent imbalance in laundry infection control, proper air pressure and temperature differential monitoring are crucial.

Failure to maintain proper intended cleansing times, temperatures, and disinfectant concentration minimums increases the risk of infection.

Following every protocol can be difficult without useful monitoring technology such as Sonicu.

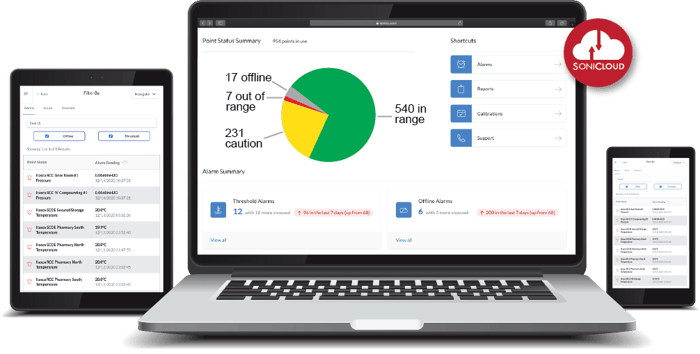

Sonic's technology allows for easy monitoring that requires little to no extra manual labor. Users can personalize their dashboards with their own customized settings and alerts that immediately notify everyone when there is a change outside of the determined settings.

Post-Wash Infection Prevention

Proper Laundering Aids In Infection Prevention

Washing alone is not enough to prevent infection.

Clean linen that becomes contaminated after the washing is just as dangerous as dirty linen before a wash. Potential contamination through textiles still remains after cleaning.

For example, linens can be exposed to contaminated air in laundry storage areas, lack of proper hand hygiene by workers, and contaminated transportation carts.

A 2015 study published in Infection Control & Hospital Epidemiology states that current infection prevention strategies for the laundering and handling of textiles are adequate in preventing healthcare-associated infections, provided that every step is taken.

Crucial steps include the following:

- Environmental cleaning

- Cart disinfection

- Airflow

Cleaning on-premise laundry area environments must also be done by themselves, regardless of incoming linens.

Regular disinfecting of services, lint control, blowdowns, and completed maintenance checklists are key to ensuring this.

While all of these systems and processes are essential to healthcare laundry safety, many organizations still follow the ASHE guidelines and invest in a cloud-based air pressure monitoring solution that can help track pressure over time.

This helps facility managers spot trends that pose a risk and provides a simple tool for compliance automation for agencies like the Joint Commission.

Some of the features of the Sonicu remote wireless monitoring system include:

- American-based Customer Service and Tech Support

- Redundancy of Power/Connectivity to protect data integrity

- SNAP calibration service for NIST compliance

- Hardware assembled in the United States

- Built on AWS Cloud for simplicity, speed, reliability and scalability

All carts, covers and liners, and containers must be properly disinfected and cleaned before each use.

This includes water splashing up from places such as the bottom of the cart or dirt and water from the corners of the transportation and storage containers.

Airflow is a crucial part of quality management that is often not paid enough attention.

Proper air quality management is achieved through the separation of air between the dirty and clean linen sides.

In order to prevent problems with laundry infection control, air pressure differential monitoring must be set up so that the clean side has positive air pressure and the dirty side has negative air pressure.

Conclusion: How to enhance your infection control practices

For easy-to-use air pressure differential monitoring that can enhance laundry infection control practice, healthcare professionals can turn to a trusted brand like Sonicu.

Sonicu’s technology is easy to install, configure, and use within any facility, regardless of the industry sector.

Users can have personalized wireless monitoring set up rapidly that sends out immediate alerts if air pressure is outside of the designated interval. And the system will make compliance reporting a snap.

Trusted by private and public labs, Sonicu delivers affordable and reliable temperature, humidity, air pressure and CO2 monitoring that protects virtually any environment.

Sonicu’s monitoring technology also automates many compliance requirements to ensure that all facilities meet regulatory agency compliance standards.

Every Sonicu customers has access to U.S.-based live phone support.

Laundry | Background | Environmental Guidelines | Guidelines Library | Infection Control | CDC

Sonicu Case Studies:

Indiana University Health: Enterprise Hospital For Temp, Humidity, Air Pressure

Problem: Server Based Monitoring Lacks Enterprise Visibility

Solution: One Window into all monitoring across dozens of facilities

Cryopoint: Ultra Low Cold Storage, Research, Lab

Problem: Too many hours spent on manual logging and calibration

Solution: Reduced Manual Logging and done-for-you calibration

Problem: Pharmacy Suffered Too Much Humidity In New Wing, impacting Compounding Pharmacy

Solution: Affordable Humidity Monitoring that Delivered Powerful data to prompt contractors to fix improperly sized air handler

Problem: Dining department struck with regulatory violations

Solution: Enterprise-wide monitoring that automates regulatory compliance across all departments

Cost competitiveness, great customer service, great control over the monitoring system, and low maintenance. You can't beat that.

Sonicu costs are considerably more reasonable than our historic system, as well as other competitors on the market. The equipment is robust but simple to learn and utilize.

Having safe and secure storage provides reassurance that any future family building efforts will be protected. Sonicu gave us the ability to more easily put our head on the pillows and sleep easier at night knowing we had invested in a strong monitoring system.”

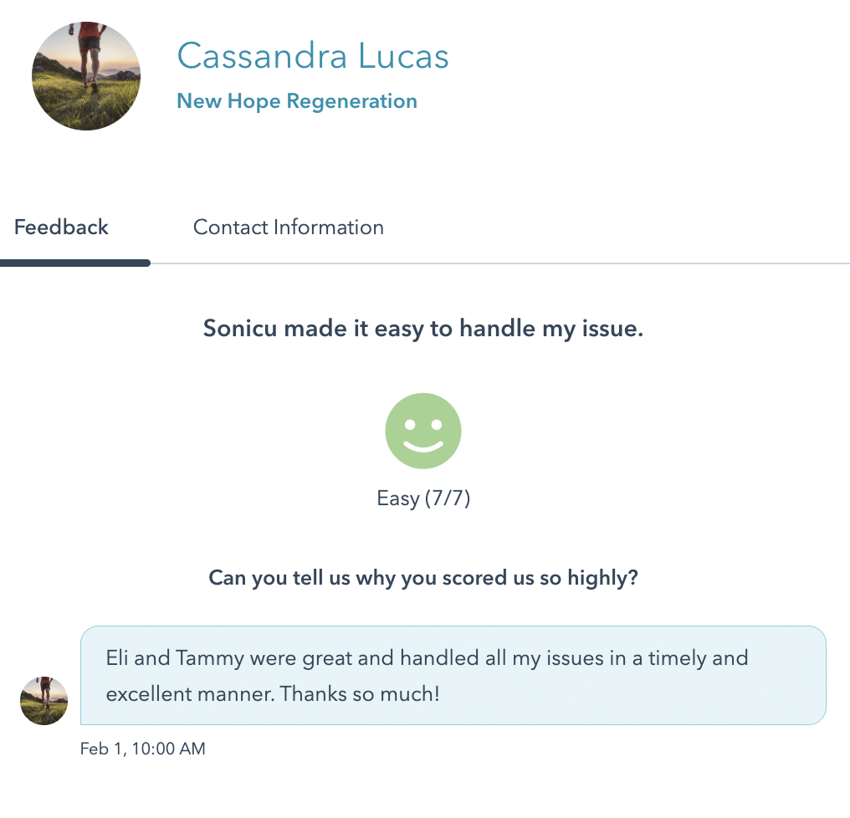

American-based Customer Support: Robust & Reliable High Touch Service

Software and technology is only as good as the people who stand behind it.

At Sonicu, that means our team of American-based customer success managers who are never more than a phone call away to help field and fix any service issues.

Our probes and sensors are placed in demanding frozen environments and our software literally sends billions bits of data monthly, meaning there’s always the potential for a hiccup on either the hardware or software.

We are committed to fielding every customer service request promptly and addressing our customer’s concerns promptly and professionally.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

We realized there had to be a better way and went in search of technology that could give us that level of monitoring that would keep our patients safe. Sonicu made it easy and we grew across the entire hospital.